Plenty Filtration: Filters | Strainers | Separators

Plenty Filtration: Filters

|

Backflush FiltersBackflushing filters are fully automatic and cover a large range of sizes and pressures with either metal or GRP bodies Principle of Operation:

|

|

Q15 Backflush FiltersQ15 Backflush Filters clean automatically without interrupting the liquid flow. Principle of Operation:

|

|

Compact Backflushing FiltersThe Plenty Filters compact type of backflush filters are specially designed for use where an automatic cleaning filter is required to ensure process continuity without manual labor.

|

|

High Pressure Self-Cleaning Filters – Manual & AutomaticSelf cleaning filters for liquid duties requiring continuous filtration without interruption to the flow during the cleaning process.

|

|

Low Pressure Self-Cleaning FiltersSelf cleaning filters for liquid duties requiring continuous filtration without interruption to the flow during the cleaning process. Self cleaning filters are available in either manual or automatic versions with standard design options for either low pressure (14 BARG) or high pressure (35 BARG) system. In operation the liquid enters the body and flows through the element from outside to inside. Debris is collected on the outside of the wedge wire element, which is cleaned without flow interruption by rotating the cylindrical element against twin scraper blades. The debris accumulated during element rotation is deposited into the bottom of the filter body from where it is periodically discharged, manually or automatically. |

|

Activated Carbon FiltersPlenty Carbon Bed Filters are of vertical fabricated construction generally mounted on skids. Works by the process of ‘absorption’ where one material adheres to another by means of physical or chemical attraction.The carbon media is extremely porous with a big internal surface area. The carbon bed removes mainly organic compounds. Features

|

|

Cartridge FiltersCartridge filters are used for removing fine contaminant from liquid flow. Principle of Operation:

|

|

Coalescer FiltersCoalescer Filters remove liquids from a gas stream with a single coalescing stage of elements. Principle of Operation: |

|

Fabricated Duplex FiltersFabricated Duplex Filter are an extremely compact design particularly suited to offshore applications. Principle of Operation: |

|

Dry Gas Filters – Horizontal & VerticalDry Gas Filters are designed to remove fine debris from a gas pipeline. Principle of Operation: Flow is inside-to-out with contaminant remaining inside the basket upon removal. Horizontal is most cost effective and maintenance friendly. Safety Interlocked quick opening closure gives quick access to the internals. |

|

Hi-Flow Filters

Size: 4″ to 60″ Bore (design pressures and flange ratings to suit requirements). Materials: Fabricated from carbon steel, stainless steel or special materials. E.g.: Cupro nickel alloy, 6Mo. Etc. Screen Material: mild steel, stainless steel or monel. |

|

Bag Filter HousingsPlenty Bag Filters houses bag type elements manufactured from man-made cotton fibre.

|

|

Filmet FiltersPlenty Filmet Filters for high flow rates requiring high efficiency.

|

|

Process Filter InternalsProcess Filter Internals are a complete range of liquid and gas elements.

|

Plenty Filtration: Strainers

|

Angle Basket StrainersAngle Basket Strainers are sized specifically to a pressure loss requirement. Principle of Operation

|

|

Bath Tub T-Type StrainersThe Bath Tub T-Type is a range of simple strainers intended for service similar to temporary conical strainers but with their own element housing.

|

|

Simplex T-Type Strainers – 2″ – 12″ NBSimplex T-Type Strainers extend the range of S-Type filters to higher pressures, suitable for both liquid and gas applications and available with bolted or quick release type covers.

|

|

Small D-Type Duplex Basket Strainers – 1″ to 8″A range of small Duplex strainers for use in pipelines operating continuously where a single (Simplex) filter can not be used as the flow would have to be interrupted to clean the element.

|

|

Large D-Type Duplex Basket Strainers – 10″ to 20″The Large D-Type Duplex Strainers offer continuous filtration during the cleaning process, for duties with large flow capacities.

|

|

Large H-Type Duplex Basket Strainers – 8″ to 36″Large H-Type Duplex Strainers offer a higher flow capacity than the same sized D Type, with sizes up to 36” connections. To complement the D Type large duplex range, the H Type offers a higher flow capacity than the same sized D Type and with sizes up to 36” connections. The H Type gives a very large capacity filter with continuous operation during basket cleaning.

|

|

Seaguard StrainersSeaguard Strainers are specially designed range of lightweight compact seawater strainers and tanker fuel handling strainers for the shipbuilding industry.

|

|

Simplus Fabricated Basket Strainers – 6″ to 20″Fabricated single basket filters incorporate a bolted or quick release cover design. Plenty offers a range of fabricated single basket filters incorporating a bolted or quick release cover design, the standard range covers sizes from 6″ (150mm) up to 20″ (500mm) class 150#, with larger sizes up to 24″ (600mm) and higher pressure rating up to class 900# also available.

|

|

Simplex S-Type Basket Strainers 1″ to 12″A general purpose cast single basket filter, suitable for use on liquid and gas, fitted with a quick-release cover for ease of maintenance.

|

|

Tanker StrainersThe Tanker range of basket filters and strainers are for use where flow can be interrupted to allow removal of element for cleaning. They have a very low profile and are well suited to situations where there is limited space to install filters.

|

|

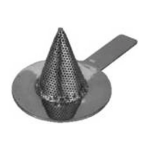

Temporary StrainersTemporary strainers are specifically designed for the filtration of debris, in the protection of fluid and gas handling equipment during the commissioning and start up periods.

|

Plenty Filtration: Separators

|

Filter SeparatorsFilter Separator units are constructed incorporating Plenty coalescing cartridges, vane units and/or cyclones to achieve the required solid and liquid removal efficiency. Designed to suit individual services and piping requirements, Plenty manufactures a comprehensive range of filter separators. Units are constructed incorporating Plenty coalescing cartridges, vane units and/or cyclones to achieve the required solid and liquid removal efficiency. Vertical Filter Separator These operating efficiencies apply over the entire flow range from maximum design down to virtually zero flow. |

|

Cyclone SeparatorsCyclone Separators are designed to remove solids and liquids from a gas pipeline. Cyclone Separators are designed to remove solids and liquids from a gas pipeline. Cyclone separators use multiple cyclone tubes to set the gas swirling. Liquids and solids are separated by centrifugal forces. Designed for a specific flow rate since reducing flows affect the cyclonic forces. The gas passing through the cyclone make them virtually self-cleaning. They operate with a relatively high pressure loss though no allowance for cleaning is necessary. Cyclone separators are virtually maintenance free. |