Albin Pump ALP pumps are suitable for pumping and dosing low or high viscous, pasty, pure, neutral, aggressive, or abrasive liquids, those containing gases or which tend to froth. Good for those containing solids in the following industries: Paint, dairy and beverage, meat and fish processing, pharmaceutical and cosmetics, waste water and water treatment, chemical and petrochemical industries, pulp and paper, textile, soap and fats, building, ceramics.

Albin Pump ALP Reliability and Cost Savings:

- Accurate and repeatable dosing and metering

- Long life

- Self-Priming

- Continuous dry running

- Lowest cost of ownership

- Quick and easy maintenance

SELF-PRIMING AND DRY-RUNNING

It is not always possible to position a pump in the ideal location, and often self-priming and dry-running performance is required. These conditions can cause wear in conventional pumps, resulting in loss of flow and premature failure. ALBIN pumps can self-prime up to 27 ft. and run dry indefinitely.

LOWEST COST OF OWNERSHIP WITH QUICK AND EASY MAINTENANCE

Leakage, clogging or blockage of conventional positive displacement pumps which incorporate seals, valves, lobes, rotors or vanes can be a regular occurrence and expensive to rectify. Albin Pumps contain the fluid in a tube or hose, requiring only one component to be changed, which means that maintenance costs are considerably lower than other pump types. Increased plant productivity and lower repair costs means pump payback is over months rather than years.

ACCURATE AND REPEATABLE DOSING AND METERING

Some industries require repeatable pump control for accurate dosing. Many traditional positive displacement pumps deliver varying flow rates, resulting in scrapped product and increased costs. Albin Pumps are accurate up to ±0.5% across their total speed range, with the additional benefit of process control capabilities which allows easy installation. Less waste means increased profits.

LONG LIFE AND GREATER RELIABILITY

Pump failure cannot be tolerated. Albin Pumps have no seals, valves, diaphragms, glands or immersed rotors to leak, clog, or replace. Abrasive, corrosive, and aggressive liquids are handled with ease because the fluid stays within the tube and never comes into contact with moving parts of the pump. The ALP range is designed and manufactured for heavy duty industrial use. The advanced elastomer technology ensures accurate and repeatable performance that truly outperforms all other pumps.

USING A PROVEN DESIGN

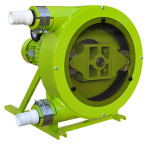

Two rollers mounted at 180° on a rotor, compress alternatively a thick-walled hose in a patented concentric guide and push the pumped liquid from the suction to the discharge side. Roller movement compresses the hose along the casing wall and creates a constant vacuum at the suction side of the pump. In this way, liquids are conveyed within the hose and do not get in contact with any metal part.

ALBIN pumps clearly outperform other pumps which rely on seals, valves, or vanes for their operation. These components are repeatedly the cause of pump failure and high maintenance. No other positive displacement pump offers this unique separation of pump and fluid. In sizes ALP 09 – ALP 25, the rotor is supported by over-sized ball bearings located within the pump casing. In sizes AL P30 – ALP 45 the rotor is supported by the heavy-duty bearings of the flanged drive unit.

The ALBIN PUMP ALP range provides flow rates from microlitres per minute to 10 cubic meters per hour and pressures up to 5 bar. Fixed, variable, flameproof, and air operated drives, with comprehensive control options to enable pumps to be configured to your requirements.

WITH EXPERT ADVICE TO GIVE THE BEST SYSTEM AND INSTALLATION… TO DELIVER THE PROMISED RESULTS

Our customers have made major improvements in process performance, maintenance and product quality, resulting in cost savings previously thought unavailable.

Albin Pump ALP Typical Applications

Water/Wastewater Treatment

Pumping / transfer / dosing of sewage thickened, sludge dewatered, sludge clarifier, waste activated sludge, digested sludge, primary sludge, lime milk, raw sludge, sodium hypochlorite, ferric chloride, sodium bisulphite, fluoride, polymers

Chemical Industry

Pumping / transfer / dosing various acids, PVDF latex, alcohol, soap, nonaromatic solvents, acids, alkalis, suspensions, stabilizers, glue, crude oil, solvents, heavy oils, cleaning of petroleum sludge food industry, in drilling plants

Food Industry

Pumping / transfer / dosing egg white & yolk, eligible fat, semolina, natural flavoring, cream, milk and yogurt, water & salt mixtures, natural flavorings, fats, fruit cake dough/mixture

Pharmaceutical

Pumping / transfer / chemical dosing, liquid protein, vaccines, serum, plasma, syrups, lotions, shampoo, liquid soap, soap emulsions, perfume, deodorants, alcohol, glycerin, sweeteners

Paint & Pigments Industry

Pumping / transfer / dosing paint, water based paint, acrylics, pigments, ink, wall coating, Solvents, paint, preservatives, glue, varnish, stains, latex, acetone, turpentine, resin