Liqui-Flux Ultrafiltration water modules represent an economical and reliable solution for your water treatment application.

Economy and Reliability in Liqui-Flux Ultrafiltration Water Modules

As an alternative to conventional treatment steps, such as flocculation, sedimentation and multi media filtration, Liqui-Flux Ultrafiltration modules reliably help remove turbidity, suspended solids from a raw water stream. Even if the inlet water quality is inconsistent, a very high quality outlet can be achieved using Liqui-Flux modules.

UltraPES and Multifiber P.E.T.™

UltraPES hollow fiber membrane is the heart of the Liqui-Flux module. It is made of polyethersulfone and consists of a distinctive 3-layer morphology that provides superior permeability and strength. To provide long-term durability the membrane is stabilized by our Multifiber P.E.T.™ Technology.

Our UltraPES Polyethersufone (PES) hollow fiber membrane provides a retentive layer on the inner side of the hollow fiber membrane.

It exhibits an extremely hydrophilic characteristic which reduces the potential of fouling. In addition UltraPES shows a high caustic resistance and free chlorine tolerance allowing Liqui-Flux modules to operate at pH values between 1 and 13.

3M’s PES membranes are known for their well defined pore structure. UltraPES demonstrates this with its distinctive three layer structure providing a highly porous support for the separation layer giving mechanical strength through thicker polymer ligaments and a protection layer on the outside with reduced pore-size to safeguard the overall membrane structure and integrity.

The pronounced asymmetric structure leads to an outstanding relation of permeability and retention rate. This allows UltraPES to achieve high volume flow at low transmembrane pressure and provides a unique way to reduce energy costs resulting in low operating costs particularly for larger filtration plants.

Features and Benefits

- Excellent permeability

- Narrow pore-size distribution

- Low pressure requirements

- Low fouling potential

- High temperature and chemical resistance (pH 1 – 13)

- Low energy consumption

Multifiber P.E.T.™ Technology

Throughout the module, 3M’s UltraPES membrane is stabilized by its Multifiber P.E.T.™ Technology.

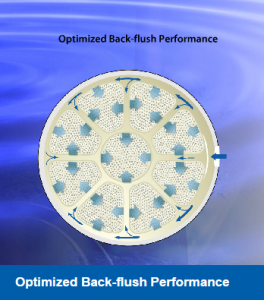

Groups of hollow fiber membranes are interlaced with a robust PET yarn, which is potted together with the membranes. This provides additional mechanical strength for the hollow fiber in the axial direction as well as during back-flushing when the fibers can experience some flexing. At the same time hydrodynamics during the back wash is improved as the yarn acts as spacer between small bundles of hollow fiber membranes. This ensures better access for the flushing water to reach all areas of the membrane sections even in the central area of a membrane segment.

Features and Benefits:

- Effective membrane stabilization

- Sustainable membrane fiber integrity

- Excellent membrane spacing

- Improves hydrodynamics during flushing

Liqui-Flux Ultrafiltration Module Design

Liqui-Flux filtration modules impress with a high membrane area and an advantageous design, allowing controlled hydrodynamic conditions through a compact size. As a stand-alone unit it features 9 discrete membrane segments each one inserted into a robust grated protection pipe, adding up to 91 m² of filtration area.

The space between the individual inserts is optimized to ensure low pressure drop during the back-flush operation making it more efficient than within a densely packed shell.

Through a moderate membrane length, Liqui-Flux modules allow for short inside flushing channels. Moreover, the introduction of back flush water from a narrowing outer ring ensures striking physical cleaning performance compared to a center tube design.

In addition all Liqui-Flux ultrafiltration modules do not contain o-ring sealing to separate the feed from the filtrate side and therefore particularly for long term applications the potential for microbiological cross-contamination is reduced.

The large surface area per module leads to reduced costs by reduced number of pipes and fittings as well as reduced mounting time particularly in larger units.

Features and Benefits:

- Optimized hydrodynamics

- Short back-flush channels

- Effective membrane cleaning

- Reliable in treating difficult feed water qualities

- No o-ring sealing to separate feed and filtrate

- Maximized filtration area – up to 91 m²

- Reduced foot-print

- Economic system costs

Liqui-Flux Ultrafiltration Module Sizes

The 91 m² Liqui-Flux® module features an advantageous design, which represents the largest ultrafiltration module of its kind with an inside-out (PES membrane) pressure driven technology. Liqui-Flux modules are available in different configurations and sizes for a range of applications:

| Liqui-Flux® W05-08N |

Liqui-Flux® W06-08N |

Liqui-Flux®; W08-07N |

Liqui-Flux® W10-08N |

Liqui-Flux® W20-08N |

| PVC | PVC | PVC | PVC | PVC |

| 8.7 m2 | 10 m2 | 66 m2 | 75 m2 | 91 m2 |

| Small-scale applications; pilot testing; sample module | Small-scale applications; pilot testing; sample module | Replacement for Ultra-Flux 55 | Large-scale industrial and drinking water applications | Large-scale industrial and drinking water applications |