Eaton Industrial Filter Bags from John Brooks Company offer reliability and efficiency. Filter Bags are an economical choice for a wide range of filtration applications. Paired with the correct filter bag housing, you can minimize process downtime, reduce or eliminate waste disposal costs, limit worker exposure to the process liquid, reduce maintenance time and expense, and improve product quality.

|

APB Filter BagsWith efficiencies greater than 99%, each ABP filter bag model provides cost-effective filtration solutions for demanding applications. The four models ensure that users can efficiently remove particles ranging from 1 – 25μm while delivering a long service life. |

|

ABSORPTION INSERT for Standard Filter BagsABSORPTION INSERT filter elements combined with standard filter bags and a stainless steel charging ring provide the ultimate solution for increased dirt and oil removal capacity. The ABSORPTION INSERT filter element fits in ACCUGAF, DURAGAF, LOFCLEAR 100 (except LCR-130), Monofilament, Multifilament, SENTINEL, SNAP RING and UNIBAG filter bags. |

|

ACCUGAF Filter BagsFilter bags for application demanding efficiencies greater than 99%. |

|

BANDSEAL Filter BagsFilter Bags for open surface filtration |

|

CLEARGAF Filter BagsCLEARGAF Filter Bags meet the requirements for EC migration performance evaluated, tested and certified by independent food research institute. They are manufactured under special conditions to ensure that they contain no contamination. To keep the filter bags contamination-free, they are individually sealed in protective plastic packaging. Fully compliant and approved for pharmaceuticals, food and beverages. |

|

DURAGAF Filter BagsThe polypropylene or polyester needle felt construction of the DURAGAF extended-life filter bags, along with the increased thickness of the filter material, significantly increases the dirt holding capacity and extends the lifetime by two to five times longer than standard needle felt filter bags. These features significantly reduce operating costs. In addition, the needle felt material with smaller diameter fibers also provides a more porous filter material while maintaining the same low initial differential pressure. |

|

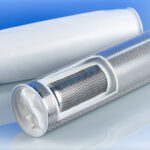

HAYFLOW Filter BagsEaton combines the benefits of a filter bag with those of a filter cartridge into a new, rugged filter element with optimum filtration performance. The filter area of HAYFLOW filter elements is up to 65% larger compared to a standard filter bag. Extended service life and long intervals between filter change-outs lead to reduced operating costs. Up to 65% more filter area in a compact, easy-to-use filter element. |

|

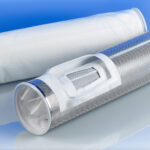

HAYFLOW Q Filter BagsHAYFLOW Q filter elements are a combination of proven DURAGAF extended-life filter material with precise nylon-monofilament woven material. While the DURAGAF extended-life filter material works as a high capacity pre- and depth filter, the outer mesh covers the needle felt and provides a final filter retention rating at 10 μm |

|

LOFCLEAR 100 Filter BagsLOFCLEAR 100 filter bags feature high-strength sewn, three-layer construction which is welded to the SENTINEL seal ring. These filter bags have efficiencies of greater than 99% over a wide range of particle sizes, with dirt-holding capacities of up to 0.55 lbs (250 g). |

|

LOFCLEAR 100 Filter Bags – AutomotiveEach of these four LOFCLEAR 100 filter bag models has a special function for paint and varnish applications in the automotive industry. |

|

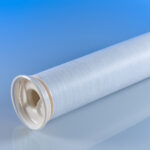

LOFCLEAR 500 Filter BagsLOFCLEAR 500 Filter Bags feature fully-welded, multi-pleated construction for high efficiency and long service life. This range has a pleated pre-filter and a complex arrangement of final filter layers, allowing the removal of difficult-to-filter gels and deformable particles with a high dirt-holding capacity. The webbed cover layer virtually eliminates any downstream fiber migration. |

|

MAX-LOAD Coreless Filter BagsMAX-LOAD coreless filter bags are manufactured from melt-blown media. Combined in a multi-graded configuration they provide an excellent dirt holding capacity. The rigid structure with a total media depth greater than 18 mm, provides a barrier to hard and metallic as well as deformable gel-type contaminants. |

|

MAX-LOAD Pleated Filter BagsMAX-LOAD pleated filter bags are manufactured from nominal rated polypropylene or polyester extended-life needle felt. The exceptional construction increases the filter bags dirt-holding capacity and lifetime by up to ten times more than standard needle felt filter bags. |

|

Monofilament Filter BagsSENTINEL and SNAP-RING monofilament filter bags feature a wide range of retention ratings. The different materials cover many applications with demanding chemical and thermal properties. These filter bags are designed for surface filtration to retain particles that are larger than the respective pore size. |

|

Multifilament Filter BagsSNAP-RING multifilament filter bags are designed for surface filtration to retain particles that are larger than the respective pore size. These filter bags are not absolute rated. |

|

PROGAF Filter BagsPROGAF filter bagsconstitute a new, high-performance alternative for applications requiring absolute filtration. The multistage filtration, with filter material that gets finer from layer to layer, provides optimum efficiency (greater than 99.9%) and a long operating life. |

|

SENTINEL Filter BagsSENTINEL filter bags comply with the industry standard of a bypass-free filter bag construction. They are available in polypropylene and polyester. |

|

SNAP-RING Filter BagsSNAP-RING filter bags are manufactured to the highest standards. Materials must meet stringent specifications for filtration performance and media purity. Production under ISO 9001: 2015 quality systems ensures reliability and repeatability from order to order, year after year. |

|

UNIBAG Filter BagsUNIBAG filter bags provide the value and reliability of a high performance filter bag seal in a fully-welded construction with the economy of a typical sewn filter bag. They are manufactured from needle felt material in polypropylene and polyester and comply with the industry standard for bypass-free filter bag construction. |