Custom Spray Nozzle Solutions – HF Mitigation System

Application #081656

Industry: Petroleum Processing

Application: HF Mitigation in the event of a leak

Product Description: 3/8″ Bete TF20FCN

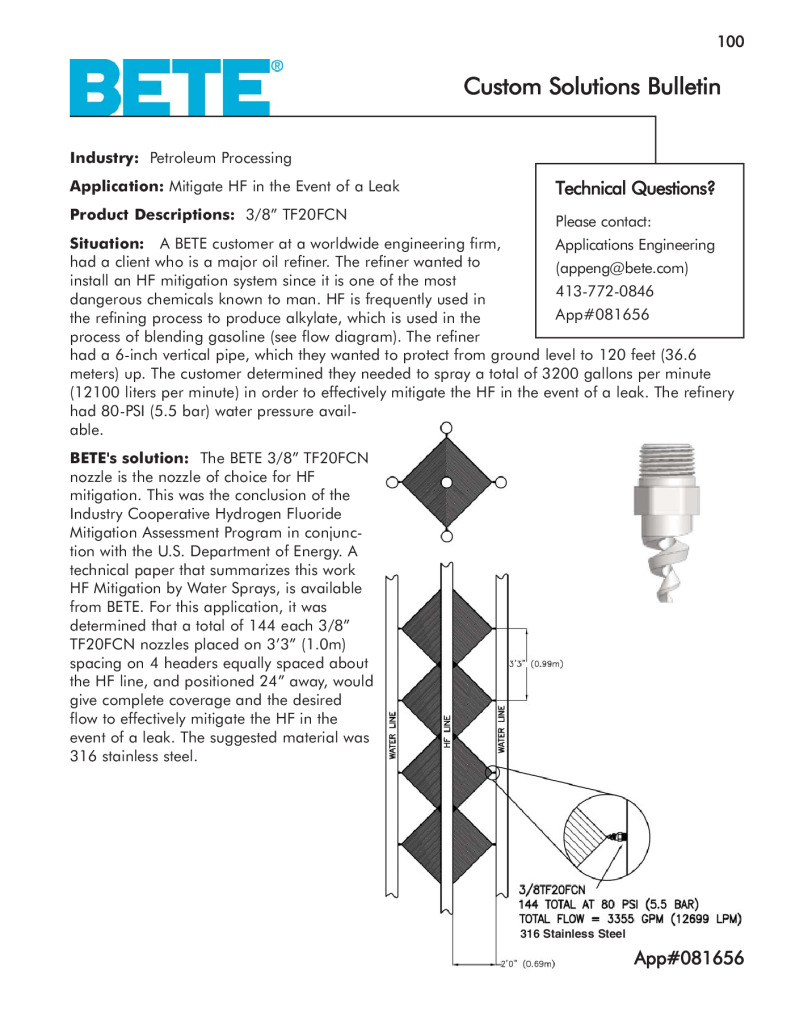

Situation: A Bete customer at a worldwide engineering firm, had a client who is a major oil refiner. The refiner wanted to install an HF mitigation system since it is one of the most dangerous chemicals known to man. HF is frequently used in the refining process to produce alkylate, which is used in the process of blending gasoline (see flow diagram). The refiner had a 6-inch vertical pipe, which they wanted to protect from ground level to 120′ (36.6 m) up. The customer determined they needed to spray a total of 3200 gallons per minute (12100 L/min) in order to effectively mitigate the HF in the event of a leak. The refinery had 80-PSI (5.5 bar) water pressure available.

Solution: The Bete 3/8″ TF20FCN nozzle is the nozzle of choice for HF mitigation. This was the conclusion of the Industry Cooperative Hydrogen Fluoride Mitigation Assessment Program in conjunction with the U.S. Department of Energy. A technical paper that summarizes this work HF Mitigation by Water Sprays, is available for download below. For this application, it was determined that a total of 144 each 3/8″ TF20FCN nozzles placed on 3’3″ (1 m) spacing on 4 headers equally spaced about the HF line, and positioned 24” away, would give complete coverage and the desired flow to effectively mitigate the HF in the event of a leak. The suggested material was 316 stainless steel.

Custom Spray Nozzle Solutions – HF Mitigation System Drawings and Sketches: