Bete WTX Spray Nozzle- Extended Life, Hollow Cone, and Tangential Whirl

In Bete tangential whirl nozzles, the liquid is introduced from the side of the chamber which causes the liquid to whirl; and produces a hollow cone pattern without the need for an internal vane. The hollow cone pattern is characterized by the heavy concentration of droplets around the edge of the spray cone. Little or no fluid is deposited in the middle of the cone. This spray pattern is a medium too low impact pattern being harder driving than the misting or full cone patterns but with less impact than flat fan or solid stream patterns.

The Bete WTX is primarily used as a dry scrubbing nozzle. With dry scrubbing, smaller amounts of fluid are sprayed into the gas flow but the volume of fluid is limited to that which can be evaporated from the gas flow. So the gas remains “dry”. This would be necessary if contamination by the scrubbing fluid is not desirable further down the process line. A fine balance needs to be found between the evaporation rate and the volume/ consistency of the spray.

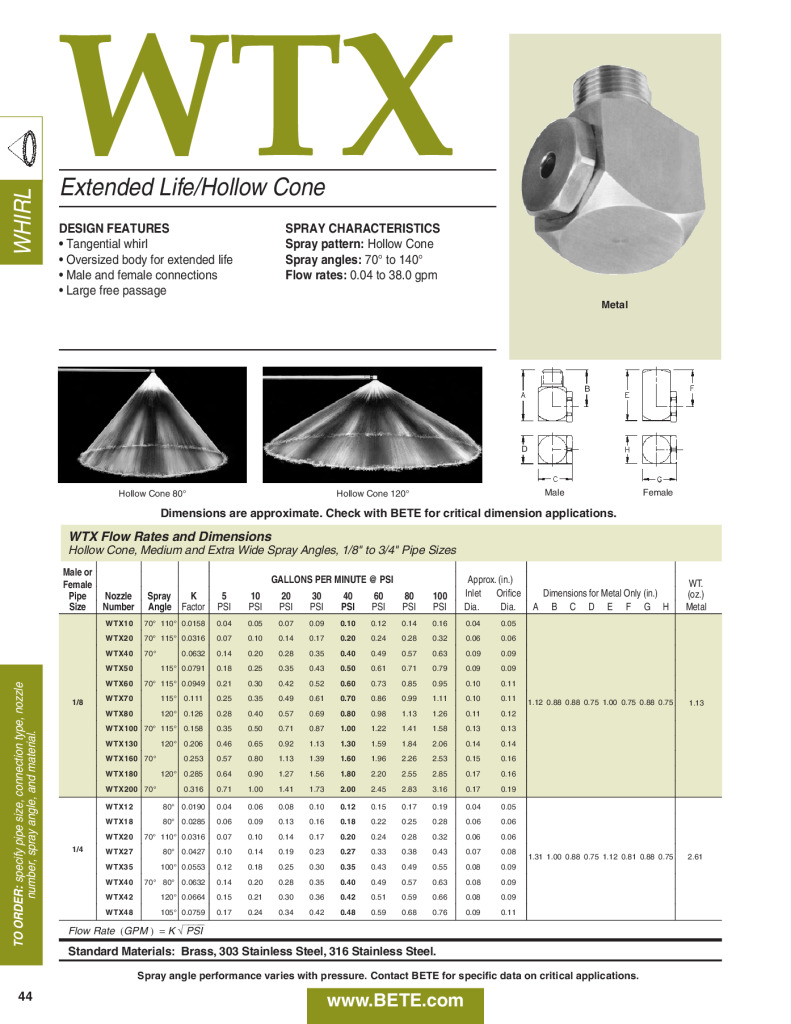

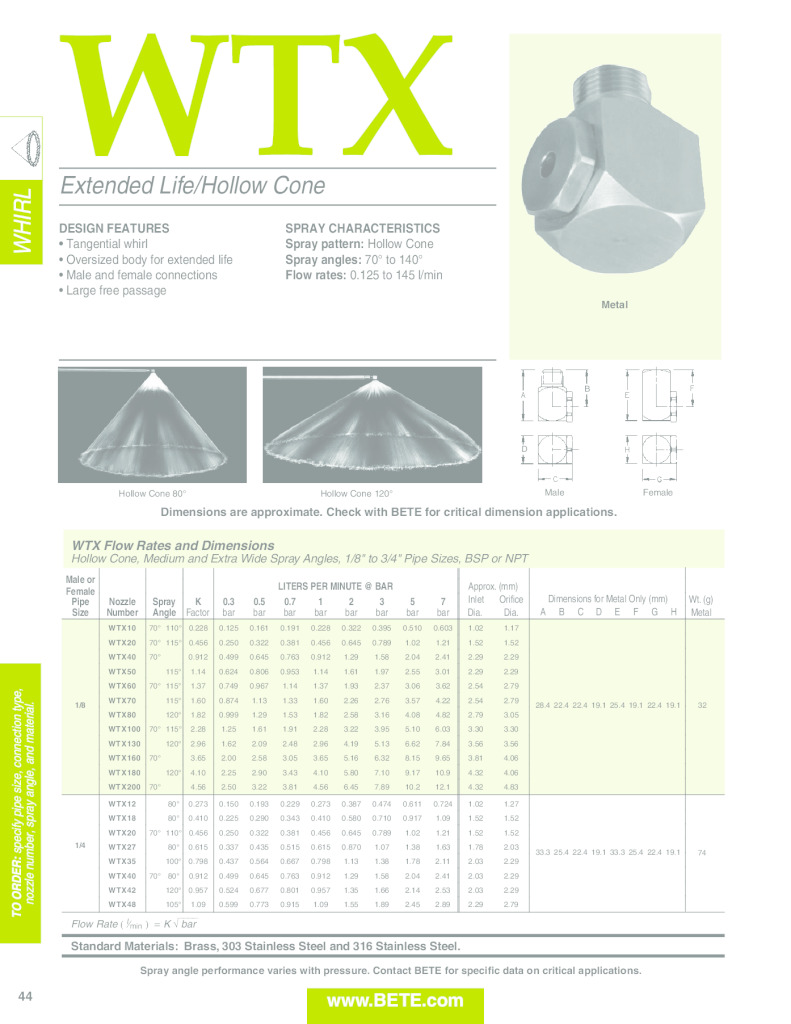

Design Features of the Bete WTX Spray Nozzle:

– Tangential whirl

– Oversized body for extended life

– Male and female connections

– Large free passage

Spray Characteristics of the Bete WTX Spray Nozzle:

Spray Patterns: Hollow Cone

Spray Angles: 70° to 140°

Flow rates: 0.04 to 38.0 gpm (0.125 to 145 L/min)

Standard Materials: Brass, 303 Stainless Steel and 316 Stainless Steel

Applications of the Bete WTX nozzle:

– Scrubbing: Dry (inject line slurry into dry scrubber)

Spay Angle Visual- Hollow Cone 80°

Spray Angle Visual- Hollow Cone 120°