Bete TDL Spray Nozzle – Hollow Cone Low Flow, Twist & Dry

Bete whirl nozzles provide uniform distribution of relatively large droplets. Tangential or axial whirl nozzles feature an internal vane within the nozzle body which cause the liquid to “whirl”. The Bete TDL (low flow, Tist & Dry) spray nozzle is part of the Bete Axial Whirl nozzle product line.

Design Features of the Bete TDL Spray Nozzle:

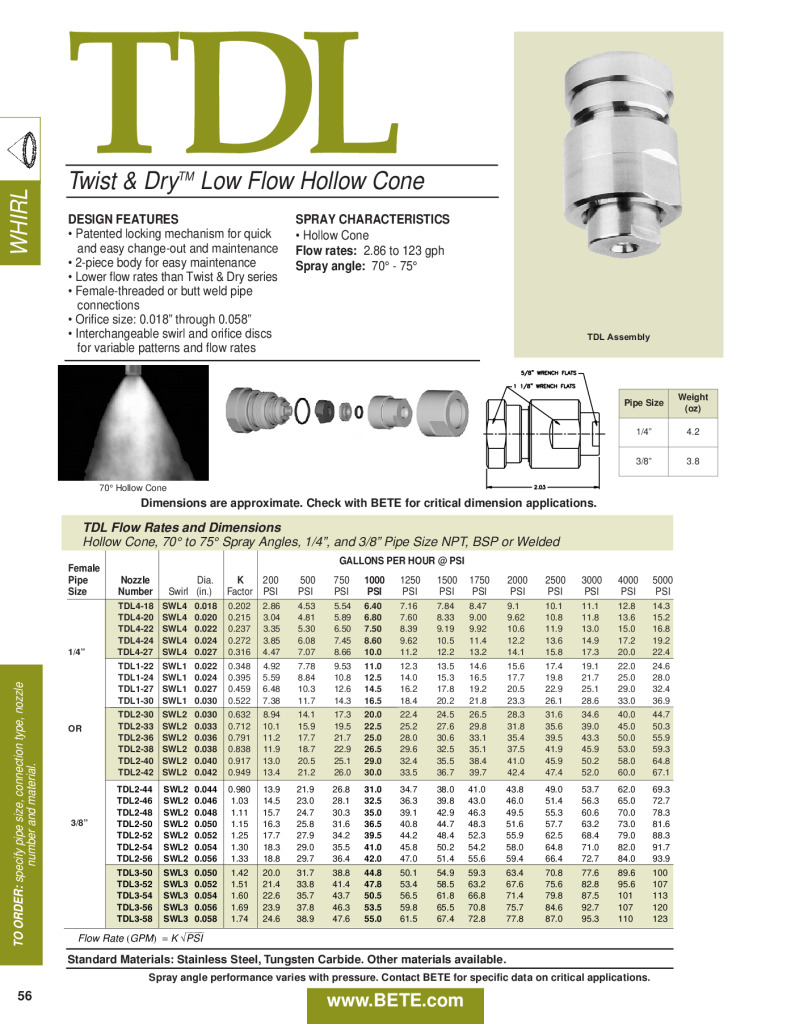

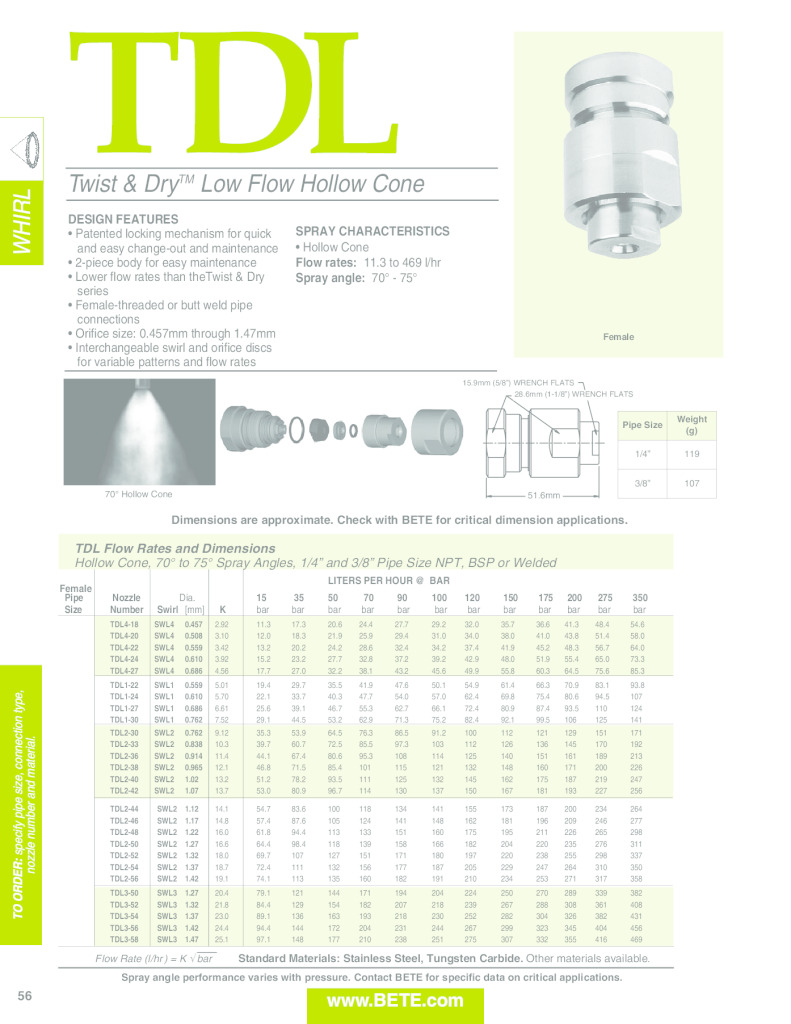

– Patent pending

– Locking mechanism for quick and easy change-out

– 2-piece body for easy maintenance

– Lower flow rates than Bete TD series

– Female threaded or butt weld pipe connections

– Orifice size: 0.018″ through 0.058″ (0.457mm through 1.47mm)

– Interchangeable swirl and orifice discs for variable patterns and flow rates

Spray Characteristics of the Bete TDL Spray Nozzle:

Spray pattern: Hollow Cone

Spray angles: 70° – 75°

Flow rates: 2.86 to 123 gph (11.3 to 469 L/h)

Applications for the Bete TDL Nozzle:

– Spray Drying (processing of milk, other foods and chemical products)