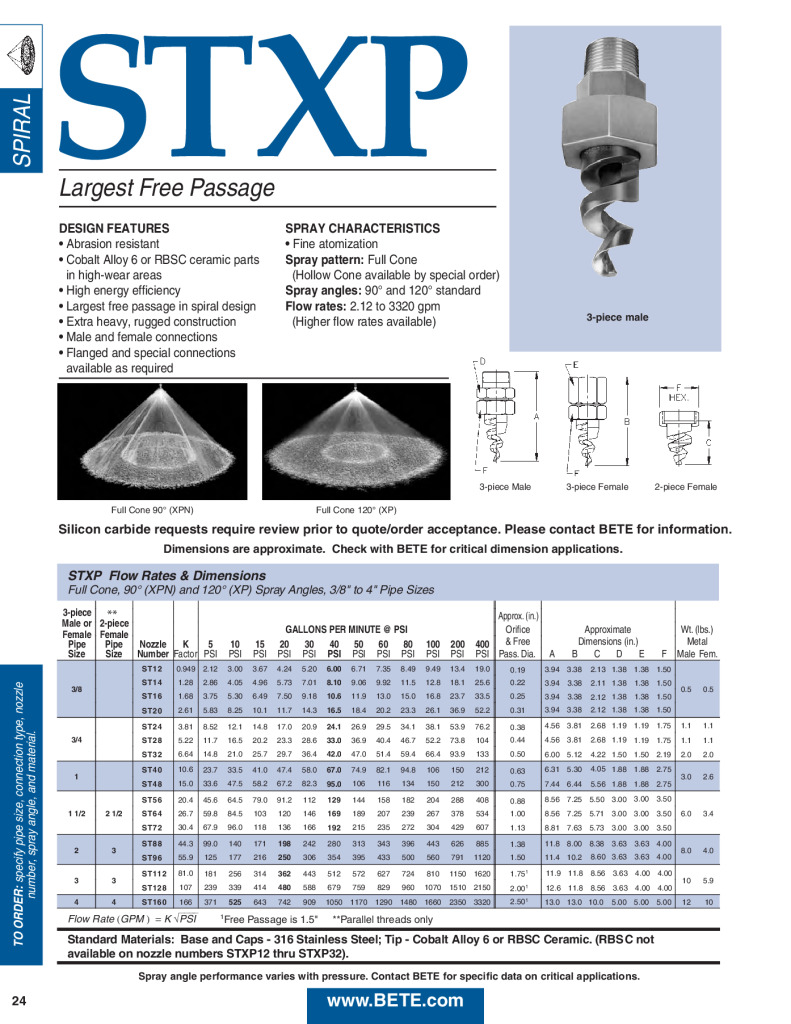

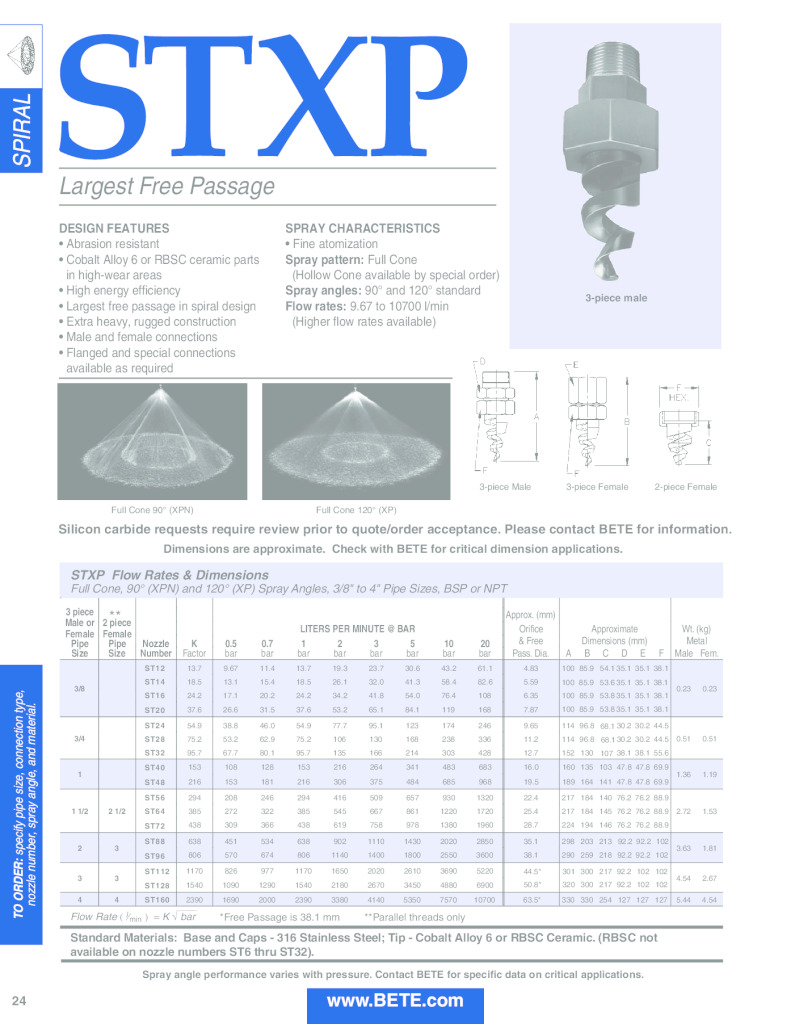

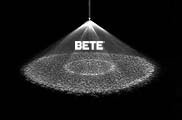

Bete STXP Spray Nozzle: Largest Free Passage Full Cone Spiral Spray Nozzle

The Bete STXP is one of the original spiral nozzles. It has a high discharge velocity and high energy efficiency. The Bete STXP spray nozzle is clog-resistant, with no internal parts.

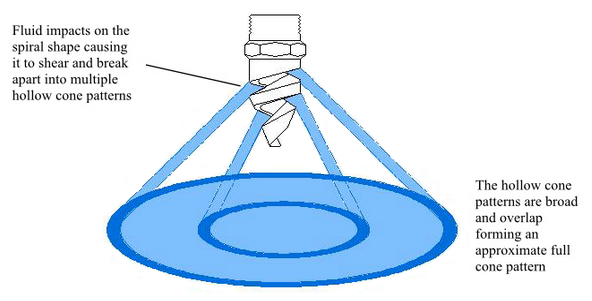

The spray pattern is formed by impacting the fluid onto a protruding helix after exit form the spray orifice. The liquid then shears off the helix, breaking into droplets and forming the spray pattern. The spirals actually produce concentric rings of multiple hollow cone spray patterns with a less uniform liquid distribution between the cones to produce an approximate full cone pattern. By varying the geometry of the helix, however, a hollow cone pattern can be achieved. Spiral nozzles will, for any given flow rate and pressure, produce a full cone spray with the smallest droplet size for any direct pressure nozzles.

Design Features of the Bete STXP Full Cone Spiral Spray Nozzle:

- Abrasion resistant

- Cobalt Alloy 6 or RBSC ceramic parts in high-wear areas

- High energy efficiency

- Largest free passage in spiral design

- Extra-heavy, rugged construction

- Male and female connections

- Flanged and special connections available as required

Spray Characteristics of the Bete STXP Full Cone Spiral Spray Nozzle:

- Fine atomization

- Spray pattern: Full Cone (Hollow Cone available by special order)

- Spray angles: 90° and 120° standard

- Flow rates: 2.12 to 3320 gpm (9.67 to 10700 L/min). Higher flow rates available.

- Standard Materials: Base and Caps – 316 Stainless Steel; Tip – Cobalt Alloy 6 or RBSC Ceramic. (RBSC not available on nozzle numbers ST6 thru ST32)

90° Spray Angle:

120° Spray Angle: