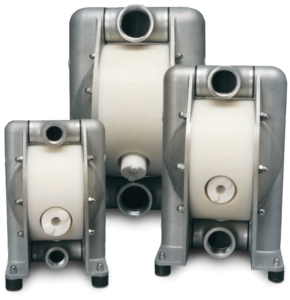

Stainless Steel Air-Operated Double-Diaphragm Pumps

The Almatec® CHEMICOR Series Stainless-Steel Air-Operated Double-Diaphragm (AODD) Pumps, are designed with special attention paid to the shape of the product chambers. The result is a pump design that offers soft changes in direction, smooth flows and no dead corners.

CHEMICOR Series pumps are manufactured from stainless steel 1.4408/SS316 (G-X 6 CrNiMo 18 10), which is a cast steel that is resistant to corrosion and acids, and is frequently used for fittings and pump casings because of its good general chemical stability. This material in a precision lost-wax casting is used for the wetted housing parts of the CHEMICOR Series. The lost-wax process is a complex casting process yielding a smooth and dense surface with increased resistance to corrosion.

Features:

- Three sizes: AD 20, AD 32, AD 50

- Max. capacities: 4.5 / 9 / 24 m3 /h (19 / 38 /105 gpm)

- Wetted housing parts made of stainless-steel precision casting 1.4408

- Special shape of the product chambers

- Pump casing with only two joint faces

- Freely turnable suction and discharge ports

- No drives, rotating parts or shaft seals

- Ball valves for liquids containing solids

- Maintenance-free PERSWING P® air control system without dead center

- Composite diaphragms with integrated metal core and no diaphragm discs

- Self-priming and dry running

- Gentle displacement

- Can be infinitely controlled via the air volume

- Unattended operation with long service life

- Compact design

- Easy to startup

- Integrated muffler

- Optional equipment available

Materials

| PART | MATERIALS |

|---|---|

| Wetted Side Housings | 1.4408 (SS316) |

| Non-Wetted Center Block | PA, PE Conductive (ATEX) |

| Diaphragms | EPDM, PTFE/EPDM, PTFE modified/EPDM, NBR, ATEX variations |

| Ball Valves | EPDM, PTFE, NBR |

Technical Data

| PUMP SIZE | AD 20 | AD 32 | AD50 | |

|---|---|---|---|---|

| Dimensions | Length, mm (inch) | 154 (6.1) | 203 (8.0) | 278 (10.9) |

| Width, mm (inch) | 150 (5.9) | 200 (7.9) | 270 (10.6) | |

| Height, mm (inch) | 241 (9.5) | 325 (12.8) | 450 (17.7) | |

| Nominal port size | BSP | 3/4″ | 1 1/4″ | 2″ |

| Air connection | BSP | 1/4″ | 1/4″ | 1/2″ |

| Weight | kg (lbs) | 6 (13) | 13 (29) | 29 (64) |

| Max. particle size of solids | mm (inch) | 9 (0.35) | 12 (0.47) | 14 (0.55) |

| Suction lift, dry: – EPDM ball valves – PTFE ball valves |

mWC (ftWC) | 2 (6.6) 1 (3.3) |

2 (6.6) 1.5 (4.9) |

3 9.8) 2 (6.6) |

| Suction lift, wet | mWC (ftWC) | 9 (29.5) | 9 (29.5) | 9 (29.5) |

| Max. operating temperature (with center block of PE conductive) |

°C (°F) | 130°(266°) 80° (176°) |

130°(266°) 80° (176°) |

130°(266°) 80° (176°) |

| Max. driving and operating pressure | bar (psig) | 7 (100) | 7 (100) | 7 (100) |

| Max. Capacities | m³/h | 4.5 | 9 | 24 |

| l/min | 75 | 150 | 400 | |

| gpm | 20 | 40 | 106 | |