The MYCO media filter provides a highly efficient and reliable means of removing solids from process liquids. The MYCO media filter is a non pressurized system which is economical and easy to operate. It can handle occasional system upsets or overloads without blinding the filter media.

The MYCO media filter is a fully automatic system that ensures efficient cleaning of any process fluid while optimizing the amount of media used. The solids are discharged as a cake for easy handling and disposal. The innovative compact design of the MYCO Media filter allows for easy integration into the following:

- Newly designed equipment

- Existing equipment

- O.E.M. systems

- Machine Tool Coolants

- Spray Booth Effluent

- Phosphating Solutions

- Parts Washing Chemicals

- Mining

- Steel

- Cooling and Heating

- Quenching Oils

- Rolling Oils

- Scrubbers

- Pulp and Paper

- Bio Diesel

- Automotive

- Agriculture

- Food and Beverage

- Machine Automation

- Water and Wastewater

Principle of Operation:

A roll of media filter paper is loaded/fed into the rear of the machine and held in place between the Sea Wheel and the stainless Steel Conveyor by conveyor belt tension force. The liquid to be filtered is pumped or fed into the inlet port and is distributed into the floodbox.

The floodbox slows the velocity of the impure liquid and spreads it over the entire width of the filter media paper forming a trough between two seal wheels. The impure liquid gravity feeds through the filter media paper removing impurities from the liquid suspension leaving a solid “cake” on the surface of the filter media paper eventually blinding off and blocking liquid passages. Clean liquid is discharged through outlet into a tank or discharged into an open system. As the solid “cake” blinds off the filter media paper the liquid level rises.

The machine automatically controls the liquid level in the machine, using a simple float probe or conductivity sensor. When the liquid level rises and the float probe contact has been made, an index cycle is initiated advancing the conveyor drive motor forward. Clean filter media paper moves forward through the machine which increases the liquid flow rate and lowering the liquid level. The “spent” media is discharged to a waste container.

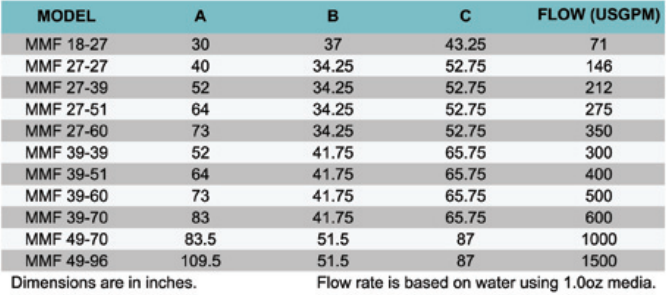

Specifications:

- – Epoxy Coated, Carbon Steel Construction

- – Conveyor Belt- 304 Stainless Steel

- – Seal Rings- neoprene

- – Steel Wheel- Aluminum or 304 Stainless Steel

Options:

- – Cover

- – Spent Media Windup

- – All Stainless Steel Construction or to Supplied Specifications

- – Custom Designed to suit application