How We Saved a Rolling Mill Customer $130K per Year with Gorman-Rupp Pumps

The Challenge:

Reusing Process Water Containing High Solid Loads

The customer is a part of the world’s leading integrated steel and mining company. This rolling mill manufactures special-grade and merchant bars reinforcing steel bars (rebar) and various other semi-finished steel products. To minimize water consumption and reuse as much process water as possible in their manufacturing process, the customer sent all water back into a sump. This sump is separated by screens into various settling pits (basins) to prevent solids from being pumped back into the system (process).

The customer’s original pumps in hardened metals kept failing, causing significant downtime that reduced the productivity of the mill. Additionally, the cost to replace the pumps was incredibly high (up to $35K). They needed a reliable, durable pump solution that could withstand highly abrasive fluids.

The Solution:

Self-Priming Pumps with Additional Coatings to Increase Abrasion Resistance

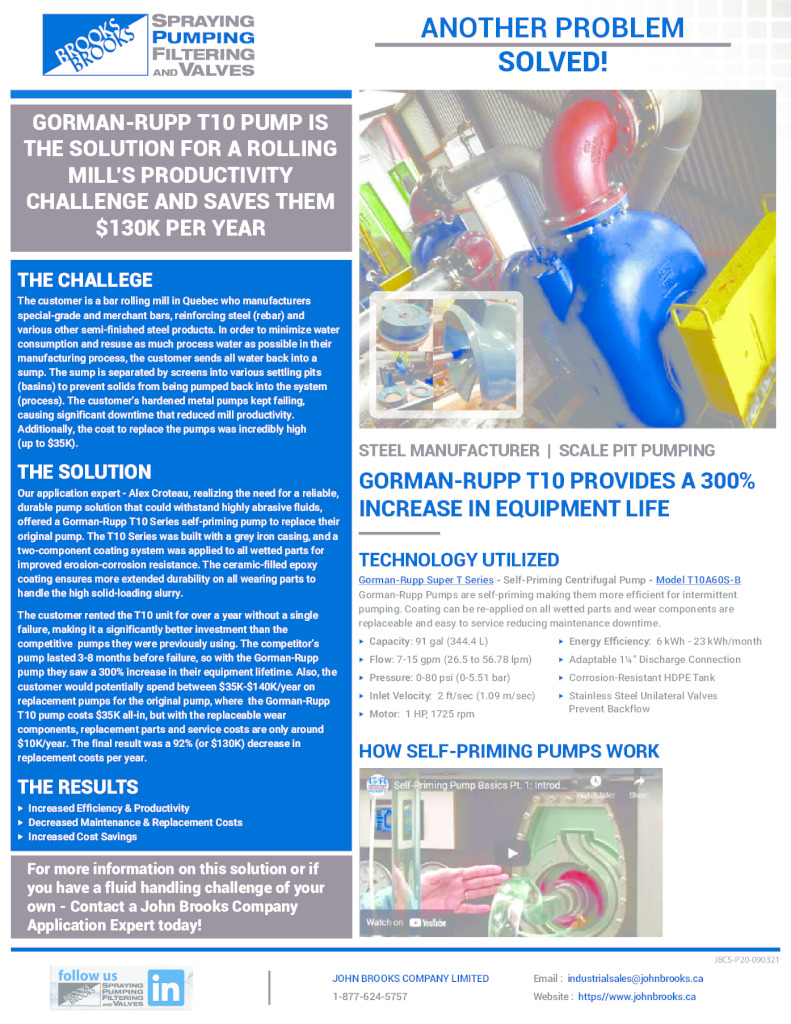

Our application expert—Alex Croteau—offered a Gorman-Rupp T10 Series self-priming pump to replace their original pump. The T10 series was built with a gray iron casing, and we applied a two-component coating system to all wetted components for improved erosion-corrosion resistance. The coating—a ceramic-filled epoxy—ensures longer durability on all wearing parts to handle this high solid-loading slurry.

Other advantages include:

- They are self-priming, making them more efficient for intermittent pumping.

- They are easier to service, which cuts down on maintenance downtime.

- The wear components are replaceable, so the customer doesn’t have to overhaul the pump regularly.

- Coating can be re-applied on all wetted components.

The Result:

A 300% increase in uptime and $130K cost savings per year

The customer rented the T10 unit for over a year without a single failure, making it a significantly better investment than the pumps they had been using from one of our competitors. The competitor’s pump lasted 3-8 months before failure, so they saw a 300% increase in their equipment lifetime.

The original pump cost $28-$35K, so the customer would potentially spend between $35K-$140K/year on replacement pumps. The GR T10 pump costs $35K all-in, but with the replaceable wear components, replacement parts and service costs are only around $10K/year. The final result was a 92% (or $130K) decrease in replacement costs per year.

Centrifugal Pump Technology Used

We solved the customer’s problems using a Gorman-Rupp Super T Series self-priming centrifugal pump Model T10A60S-B

Gorman-Rupp Super T Self-Priming Pumps

Gorman-Rupp Super T Self-Priming Pumps (SOLIDS & CORROSIVE LIQUIDS PUMPS) are designed...