- Call: 1-877-624-5757

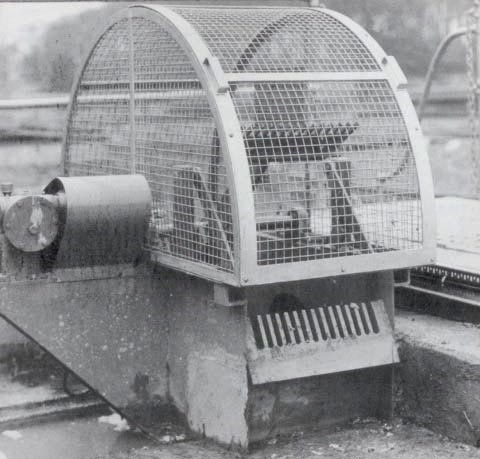

Centrifuges | Filter Press |Screw Press |Belt Press | Self-Indexing Media Filters

Dewatering equipment is designed to separate water from solids using force, including vacuum and centrifugal motion. Used widely in waste management, dewatering equipment can save money by reducing solids handling or disposal expenses that are charged on a unit weight basis. The weight percentage of water in landfill-bound solids and raw wastewater sludge can effectively double or triple the cost of removal or treatment services.

Depending on the type of solid and the size of the operation, dewatering can be more cost effective than heat drying systems for water removal because the energy cost to power an oven or microwave can be much higher than to power a motor or pump. It may also be easier to streamline dewatering methods into a process line. In applications demanding very high levels of water removal, dewatering is used generally as the preliminary method, and is followed by stages of heat drying or digestion.

Selecting a Dewatering Method:

Characteristics of dewatering equipment vary by method. However, the same performance specifications and design considerations are applicable to all dewatering technologies. Specifications that describe dewatering performance include cake dryness, solids recovery and drying time. Considerations for design and operation of this equipment include operating costs, chemical usage, and required maintenance.

The OR-TEC OSA Shaftless Screw Auger is ideal for transporting dewatered sludge,…

OR-TEC Rotary Brush Screens are perfect for MBR membrane bioreactors, the headwork’s…

OR-TEC Rotating Bar Screens are perfect for fine and coarse screening influent…