1-1/2″ | 38 mm Pro-Flo Series Clamped Metal Pump

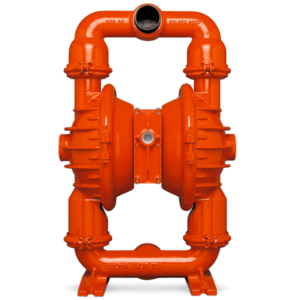

Wilden P8 Pro-Flo Clamped Metal AODD Pumps ensure reliability without sacrificing ease of maintenance. With simple installation and easy serviceability, it’s ready for rugged utilitarian applications that require a robust design. Featuring the Wilden original air-operated double-diaphragm pump design, clamped metal pumps offer a simple, rugged design for general industrial applications. Designed with ease of maintenance in mind, clamped pumps are simple to install and are made for quick serviceability, allowing the pump to be taken apart and put back together with only a single tool.

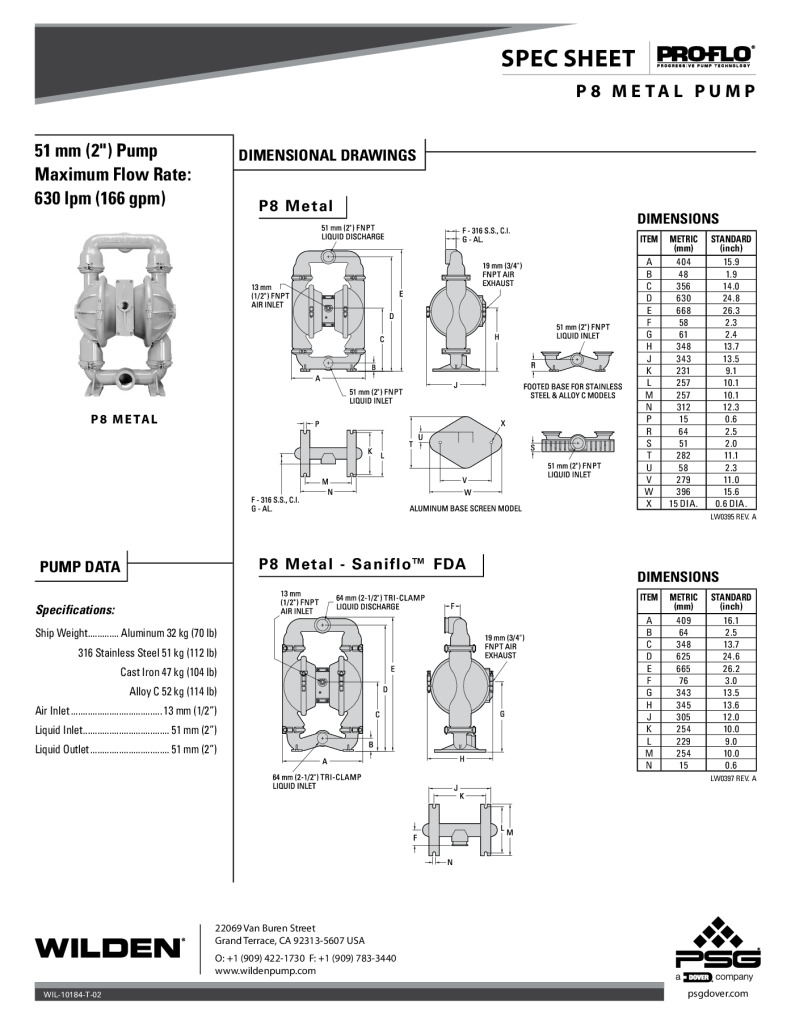

| AIR INLET: | 1/2″ FNPT |

| CONNECTION TYPE: | NPT/BSPT (Threaded) |

| MAX PRESSURE: | 125 psi (8.6 bar) |

| LIQUID INLET: | 2″ (51 mm) |

| LIQUID DISCHARGE: | 2″ (51 mm) |

| MAX FLOW RATE: |

Rubber = 165 gpm (623 lpm) |

| TPE = 166 gpm (630 lpm) | |

| PTFE – Full-Stroke = 163 gpm (618 lpm) | |

| PTFE – Reduced-Stroke = 131 gpm (496 lpm) | |

| Ultra-Flex™ = 139 gpm (526 lpm) | |

| MAX DIAMETER SOLIDS: | 1/4″ (6.4 mm) |

| MAX SUCTION LIFT CAPABILITY: |

Rubber = DRY – 22.70′ (6.9m) | WET – 28.4′ (8.6m) |

| TPE = DRY – 22.1′ (6.7m) | WET – 28.4′ (8.6m) | |

| PTFE – Full-Stroke – DRY – 22.10′ (6.7m) | WET – 29.5′ (9.0m) | |

| PTFE – Reduced-Stroke – DRY – 15.0′ (4.6m) | WET – 31.0′ (9.5m) | |

| Ultra-Flex™= DRY – 16.0′ (4.9m) | WET – 29.0′ (8.8m) | |

| DISPLACEMENT PER STROKE (1 cycle = 2 strokes): |

Rubber = 0.70 gal (2.6 L) |

| TPE = 0.75 gal (2.8 L) | |

| PTFE – Full-Stroke = 0.70 gal (2.6 L) | |

| PTFE – Reduced-Stroke = 0.44 gal (1.67 L) | |

| Ultra-Flex™ = 0.56 gpm (2.12 L) |

Benefits and Features:

- NPT and BSP threaded inlet/discharge liquid connections for quick disconnect/connect

- Decades of Proven Performance

- Clamped Connections for Faster Maintenance

- Low Cost

- Simple Installation

- Ease of Operation & Maintenance

Wetted Housings |

Non-Wetted Housings |

|||

| MATERIAL | SHIP WEIGHT | DESCRIPTION | MATERIAL | |

| Aluminum | 70 lbs (32 kg) | Center Block | Polypropylene | |

| Stainless Steel | 112 lbs (51 kg) | Air Valve | Polypropylene | |

| Cast Iron | 104 lbs (47 kg) | Air Chamber | Aluminum, PFA-Coated, Nickel-Plated, Stainless Steel, Halar-Coated Aluminum | |

| Alloy C | 114 lbs (52 kg) | |||

Elastomer Options

| Material | Temperature Limits |

|---|---|

| Buna-N | 10°F to 180°F (-12°C to 82°C) |

| EPDM | -60°F to 280°F (-51°C to 138°C) |

| FKM | -40°F to 350°F (-40°C to 177°C) |

| Neoprene | 0°F to 200°F (-18°C to 93°C) |

| PTFE | 40°F to 220°F (4°C to 104°C)

40°F to 300°F (4°C to 149°C) – 13 mm (1/2″) and 25 mm (1″) models only |

| Polyurethane | 10°F to 150°F (-12°C to 66°C) |

| Saniflex™ | -20°F to 220°F (-29°C to 104°C) |

| Wil-Flex™ | -40°F to 225°F (-40°C to +107°C) |

Certifications

CE Mark (Conformité Européene – European Conformity)

Wilden Pump & Engineering LLC has met the criteria for placing the CE mark on our product line. On December 3, 1999, Wilden fully self-certified its product line by meeting all the regulations of the Machinery and PED (Pressure Equipment) Directives. Every pump manufactured by Wilden will now receive the CE mark. Each pump box will also include a Safety Supplement manual in the eleven official languages of the European Community. This CE mark certification is indicative of Wilden’s pledge to providing our distributor network with all the sales tools necessary to excel in a global economy.