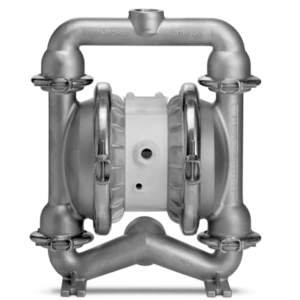

1-1/2″ | 38 mm Saniflo FDA Series Clamped Metal Pump

Wilden P4 Saniflo FDA Clamped Metal AODD Pumps ensure reliability without sacrificing ease of maintenance. With simple installation and easy serviceability, it’s ready for rugged utilitarian applications that require a robust design. Featuring the Wilden original air-operated double-diaphragm pump design, clamped metal pumps offer a simple, rugged design for general industrial applications. Designed with ease of maintenance in mind, clamped pumps are simple to install and are made for quick serviceability, allowing the pump to be taken apart and put back together with only a single tool.

- Tri-Clamp® connections with wingnut clamped design

- Quick breakdown/reassembly for cleaning

- Shear sensitive

- Robust durability

- Straight flow-through design

Wilden® Saniflo FDA Series Pumps for Hygienic and Sanitary Applications

Wilden Saniflo™ FDA Series pumps are designed for standard food applications that don’t require the Hygienic™ Series (HS) design or clean-in-place (CIP) capability. They are well suited for sanitary applications moving high-acid, high-sugar and high-fat media. With simple installation and robust design, FDA pumps comply with FDA, CE, EC 1935/2004 and ATEX requirements.

Applications Include:

- Food and Beverage

- Prepared Food and Sauces

- Poultry and Dairy

- Sweeteners and Acids

|

|

|

|

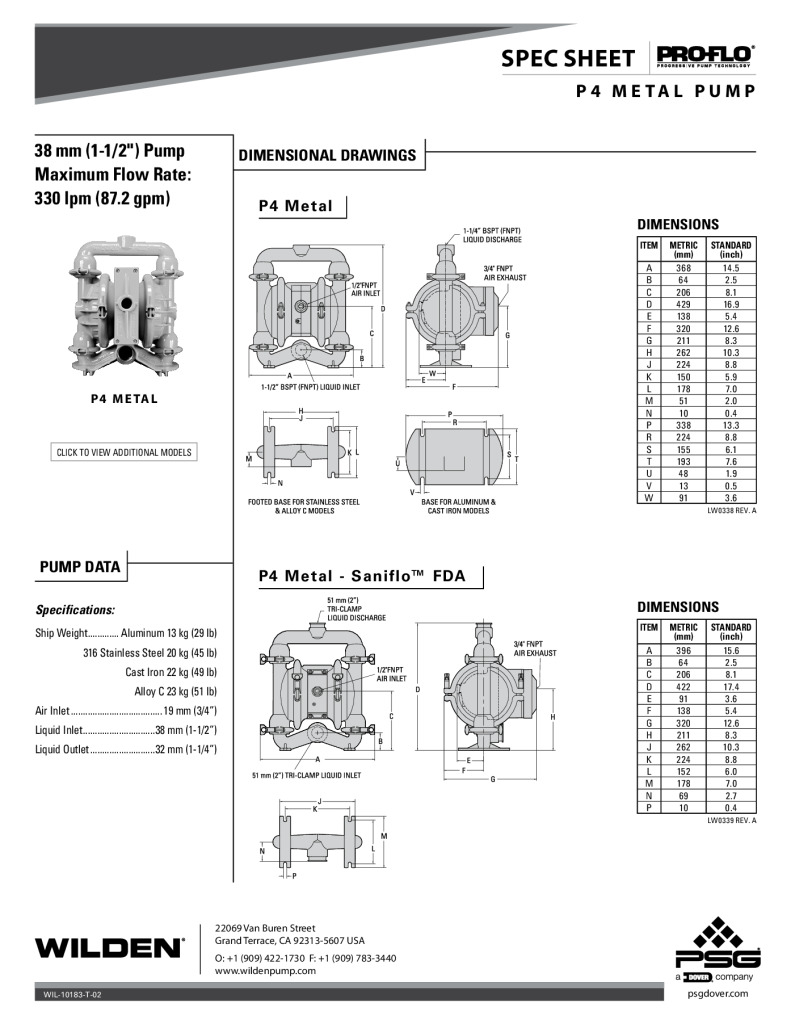

| AIR INLET: | 1/2″ (13mm) | |

| LIQUID INLET: | 1/2″ (13mm) | |

| LIQUID DISCHARGE: | 1/2″ (13mm) | |

| CONNECTION TYPE: | Tri-Clamp® | |

| MAX PRESSURE: | 125 psi (8.6 bar) | |

| MAX DIAMETER SOLIDS: | 3/16″ (4.8 mm) | |

| MAX FLOW RATE: |

Rubber: 76 gpm (76 lpm) | |

| TPE: 81 gpm (81 lpm) | ||

| Full-Stroke PTFE: 87.2 gpm (330 lpm) | ||

| Reduced-Stroke PTFE: 78 gpm (295 lpm) | ||

| Ultra-Flex™: 71 gpm (269 lpm) | ||

| MAX SUCTION LIFT CAPABILITY: |

Rubber: DRY – 19.0′ (5.8m) | WET – 26.0′ (8.0m) | |

| TPE: DRY – 17.0′ (5.2m) | WET – 29.0′ (8.8m) | ||

| Full-Stroke PTFE: DRY – 21.0′ (6.4m) | WET – 30.6′ (9.3m) | ||

| Reduced-Stroke PTFE: DRY – 12.0′ (3.7m) | WET – 28.0′ (8.5m) | ||

| Ultra-Flex™: DRY – 17.0′ (5.2m) | WET – 28.0′ (8.5m) | ||

| DISPLACEMENT PER STROKE (1 cycle = 2 strokes): |

Rubber: 0.26 gal (0.98 L) | |

| TPE: 0.29 gal (1.1 L) | ||

| Full-Stroke PTFE: 0.29 gal (1.1 L) | ||

| Reduced-Stroke PTFE: 0.14 gal (0.53 L) | ||

| Ultra-Flex™: 0.20 gpm (0.76 L) |

Wetted Housings |

Non-Wetted Housings |

|||

| MATERIAL | SHIP WEIGHT | DESCRIPTION | MATERIAL | |

| Stainless Steel | 45 lbs (20 kg) | Center Block | Polypropylene | |

| Air Valve | Polypropylene | |||

| Air Chamber | Aluminum, PFA-Coated, Stainless Steel, Halar-Coated | |||

Elastomer Options

| Material | Temperature Limits |

|---|---|

| Buna-N | 10°F to 180°F (-12.2°C to 82.2°C) |

| EPDM | -60°F to 280°F (-51°C to 138°C) |

| FKM | -40°F to 350°F (-40°C to 177°C) |

| PTFE | 40°F to 220°F (4°C to 104°C)

40°F to 300°F (4°C to 149°C) – 1/2″ (13mm) and 1″ (25mm) models only |

| Saniflex™ | -20°F to 220°F (-29°C to 104°C) |

| Wil-Flex™ | -40°F to 225°F (-40°C to 107°C) |