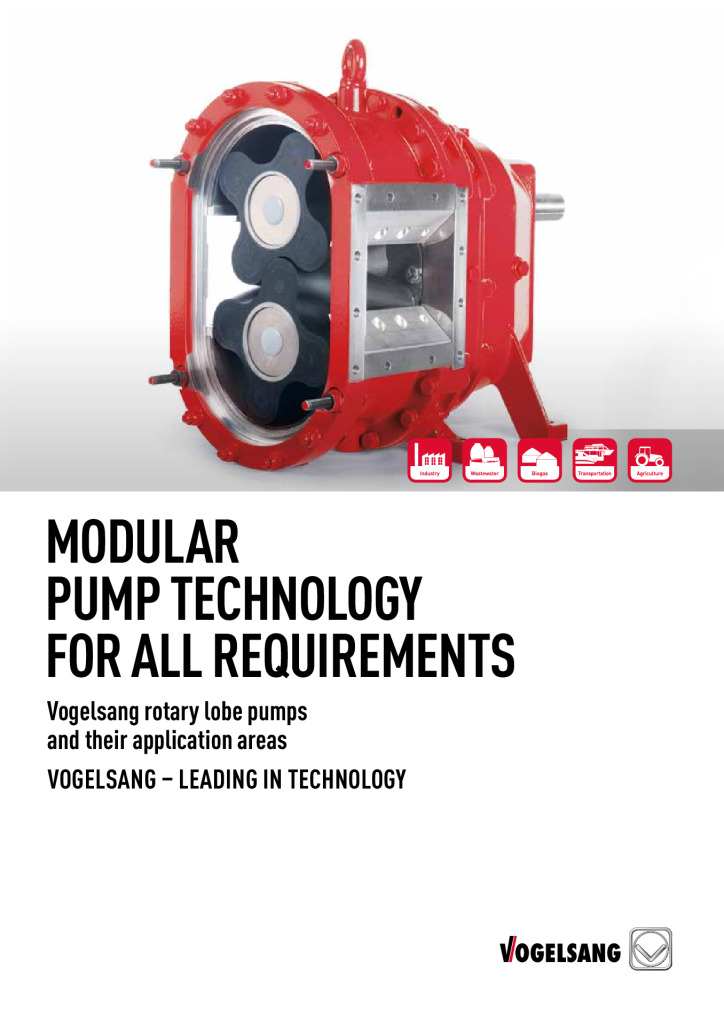

Rotary Lobe Pumps for Every Application

The VX series is the all-rounder from Vogelsang. Currently comprised of five models, more than 25 different sizes, a wide variety of drive variants, and a comprehensive range of features and options, the rotary lobe pumps in the VX series are unbeatable. They can be individualized, custom-fit and installed in almost any application. Whether as a pump in agriculture, for applications in industry, in a sewage treatment plant or biogas plant, or for supply and disposal solutions in the transport sector – decades of experience from the inventor of the rotary lobe pump flow into the continuous improvement process for our pumps, ensuring satisfied customers across industries, now and in the future.

Thanks to key technical innovations, such as the InjectionSystem, our pumps are improved continuously. As proven in field trials, the InjectionSystem further expands resistance to foreign matter, extending the already long service life of the pumps by a factor of up to 2.5. At the same time, the innovative InjectionSystem has a positive impact on the suction of the rotary lobe pump and on its efficiency.

Optionally, Vogelsang rotary lobe pumps can also be installed in compliance with ATEX or the TA-Luft air quality control guidelines.

There are currently five models in the Vogelsang VX series:

- VX100: The small VX100 pumps media with capacities of up to 50 m³/h at pressures of up to 10 bar, making it suitable for either simple or very specific applications.

- VX136: Compact and easy to maintain, the VX136 achieves capacities of up to 364 m³/h and enables pressures of up to 16 bar – the perfect solution for all industries.

- VX186: Powerful and sturdy rotary lobe pump technology is provided by the pumps in the VX186 series. If you need to pump abrasive, viscous or aggressive media, for example, it provides the ideal solution, with capacities of up to 1,025 m³/h and pressures of up to 16 bar.

- VX215: The VX215 is particularly well suited to applications that demand maximum capacities and a large free passage. It pumps media at up to 1,417 m³/h and pressures of up to 8 bar.

- VX230: The VX230 features a high capacity combined with the advantageous characteristics of the VX series. With capacities of up to 1,234 m³/h at pressures of up to 12 bar, the VX230 rotary lobe pumps are mainly used in the waste water segment and in industry.

The VX series can be serviced quickly and easily on site with the QuickService design – without having to dismount the pump. Only the cover of the rotary lobe pump has to be removed to provide access to the most important components, such as the patented HiFlo lobes, the axial wear plates or the adjustable pump housing segments.

Maintenance of the VX Pump

1. Open the Cover: Unfasten four nuts, remove the cover and you have free access to the pumping chamber. If necessary, you can also replace the wear plate of the cover at this stage.

2. Dismount the rotary lobes: Unfasten the strain bolts, remove the pressure discs on the lobes. Then place the puller on the lobes and dismount them.

3. Remove the wear plates: After you have removed the lobes, all you have to do is remove two screws and you can remove the wear plate at the gearbox side.

4. Remove the Quality Cartridge mechanical seal: Using a simple pull-out device, you can now pull out the Cartridge mechanical seal and then replace it just as easily.

5. Assembly: Insert the wear plate at the gearbox side, fasten it with two screws, install the lobes and fasten them on the shaft with pressure discs, and put the cover in place.

Shaft Warranty

A large cross-section, no recesses – the result: Vogelsang pumps have break-resistant shafts! And thatʼs how we can – under the normal conditions of use in accordance with our terms of warranty – provide a five-year warranty against internal shaft breakage for all pumps in the VX series.

Special Designs

Upon request, Vogelsang can also develop special designs in-house to meet your specific requirements.

For Example:

- Multi-chamber pumps

- Long-shaft pumps

- Submersible pumps

- Mobile pump units

- Combinations of drives

- TA Luft-compliant (German Air Pollution Control Regulation)

- ATEX-compliant