How We Increased Production and Improved Operational Efficiency for Our Customer

The Challenge:

A leading egg processing company was challenged with the continuous breakdown of their CIP pumps in their clean-in-place sanitary process. The pumps were leaking and needed replacement every six months due to their inability to handle the caustic chemicals being used in the sanitation process, creating an increase in capital costs. The constant breakdowns and replacement requirements caused unscheduled downtime, production loss, and the leaks were a potential safety hazard.

The Solution:

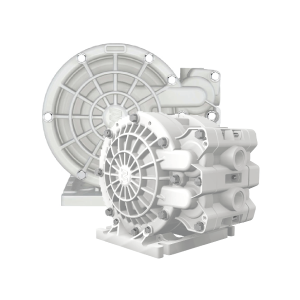

Our Application Expert – Chris Slawson – met with the Customer and after an evaluation of the process, found that the pumps being used were not suitable for pumping caustic chemicals, and recommended the Wilden Velocity AODD Pump as a replacement. This particular pump was chosen because of its competitive price, versatility, and reliability. The Wilden Velocity Pump consumed less air than the existing pumps and had fewer parts – reducing breakdown possibilities. Also, its bore-seal design eliminates leaks that result from torque decay. Since the installation of these pumps, the Customer has not had any problems.

AODD Pump Technology Used

The Wilden® Velocity Series compact air-operated double-diaphragm (AODD) pump was designed with versatility. Featuring a unique detachable mounting foot, Velocity Series pumps can easily be reoriented into a vertical or horizontal position with multiple inlet and discharge port options, a critical consideration for systems and skids.

Pump Specifications & Benefits

- 4.3 m (14.2′) dry suction lift for better priming

- Startup pressures as low as 1.03 bar (15 psi)

How Wilden AODD Pumps Work

An Air-Operated Double-Diaphragm pump (AODD) is a positive displacement (PD) pump. It has two flexible diaphragms that alternate filling and discharging two pumping chambers as they move. On opposite sides of the filling and discharging chambers, compressed air feeds into and vents from air chambers that create the pumping action.

Because of how the pump operates, it can self-prime, deadhead, and run dry with low shear. This allows it to quickly reach and maintain the desired flow rate throughout an entire production run and withstand the abrasion of the shear-sensitive fluids.

Wilden Velocity Compact Pumps for Skids, Systems and Dosing Applications

Wilden Velocity Compact Pumps are air-operated double-diaphragm (AODD) pumps – designed with...