How the Seepex BN Range Pumping Transport System increases productivity and saves up to 1 million dollars a year in transportation costs.

The Challenge:

The customer engages in the exploration and production of oil, natural gas, and sulphur and transports and wholesales petroleum and petroleum products.

Part of the customer’s process involves extracting heavy crude oil and produced water from the ground at the production wells and sending it into a hydrocyclone, which separates the oil from the produced water.

The produced water, which comprises water, sand, and chlorides, is then transported to multiple remote sites that are, on average, eight to twelve kilometres (four to eight miles) away from the production wells for treatment before it can be put back in the ground.

Trucking the produced water is extremely time consuming and expensive and can cost the customer between $500,000.00 to $1,000,000.00 per year in transportation costs.

The Solution:

Our application expert—Steve Jesudian—offered SEEPEX BN Range Pumps with equal wall stator technology and hydraulic motor to pump the produced water to the remote sites for treatment, replacing the need for trucking.

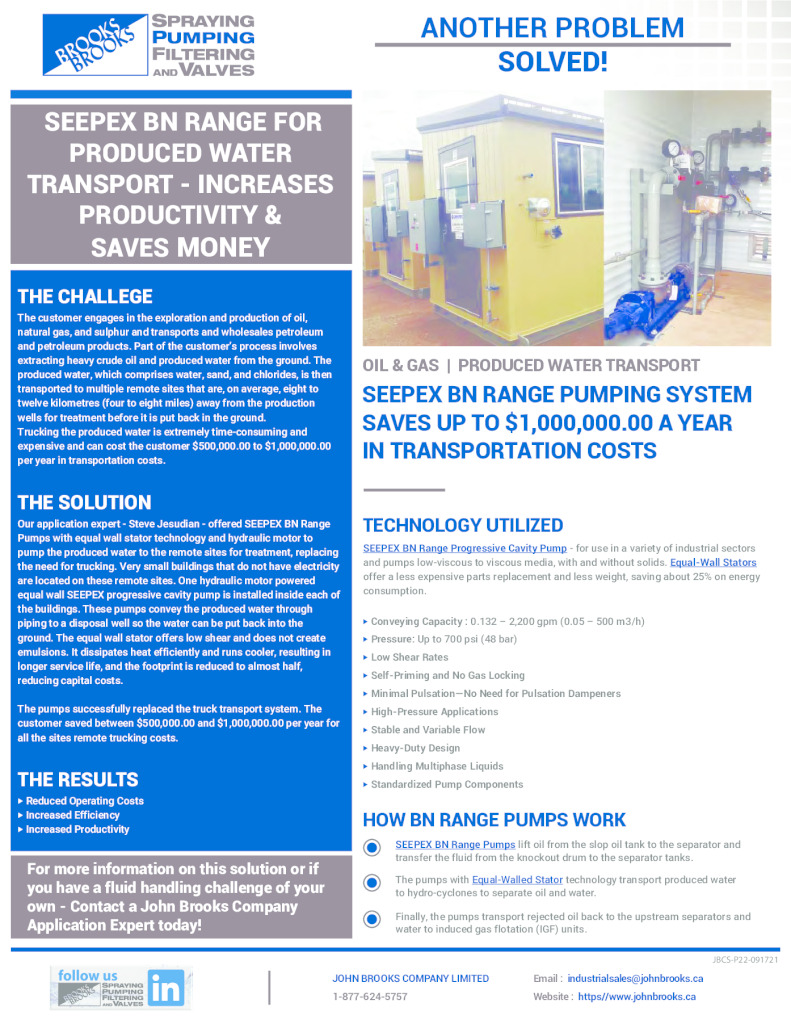

Very small buildings that do not have electricity are located on these remote sites. One hydraulic motor powered equal wall SEEPEX progressive cavity pump is installed inside each of the buildings. These pumps convey the produced water through piping to a disposal well so the water can be put back into the ground.

The BN Range of pumps are designed for the oil and gas industry and with the correct pressure, can tie in multiple remote wells at considerable distances. These pumps can operate with low NPSH requirements, eliminating the need for a separate booster pump.

The equal wall stator offers low shear and does not create emulsions. It dissipates heat efficiently and runs cooler, resulting in longer service life and, since less space is required for installation and essential maintenance, the footprint is reduced to almost half reducing capital costs.

The Result:

The pumps successfully replaced the truck transport system, which accomplished the customer’s goals of streamlining their water treatment process while reducing costs. The customer saved between $500,000 and 1 million per year for all the sites remote trucking costs.

Although the pumps have to transport water four to eight miles from the production wells, their high-pressure capabilities (up to 700 psi/48 bar) manage with no issue.

The equal wall stator also reduced their footprint by almost half, prompting them to reduce their building size to save even more money.

SEEPEX BN Range Pump Specs

- Conveying Capacity: 132 – 2,200 gpm (0.05 – 500 m3/h)

- Pressure: up to 700 psi (48 bar)

Benefits of SEEPEX BN Range Pumps

- Low shear rates

- Self-priming and no gas locking

- Minimal pulsation—no need for pulsation dampeners

- Stable and variable flow

- High-pressure applications

- Heavy-duty design

- Handling multiphase liquids

- Standardized pump components

How the Pumps Work for Produced Water Transport

- BN Range pumps lift oil from the slop oil tank to the separator and transfer the fluid from the knockout drum to the separator tanks.

- The pumps with equal walled stator technology transport produced water to hydro-cyclones to separate oil and water.

- Finally, the pumps transport rejected oil back to the upstream separators and water to induced gas flotation (IGF) units.

SEEPEX N – Standard Pumps

SEEPEX N – Standard Pumps SEEPEX N pumps are the basis for SEEPEX...

SEEPEX Stators

SEEPEX Stators – Individually Made SEEPEX stators are custom-made for every size...