SEEPEX Open Hopper Pump Increases Employee Safety & Improves Efficiency in a Vegetable Processing Plant

The Challenge:

A vegetable processing plant in Southern Ontario was having issues with potato peel trims. They were recycling the trims for animal feed and manually transferring it to outside bins. This process was labour-intensive and hazardous due to the water and potato trims accumulating on the floor, making the area slippery and dangerous. The customer needed a solution that would increase safety, reduce labour costs and operate without adding water, since they would not be able to use the trims for animal feed if they were too wet.

The Solution:

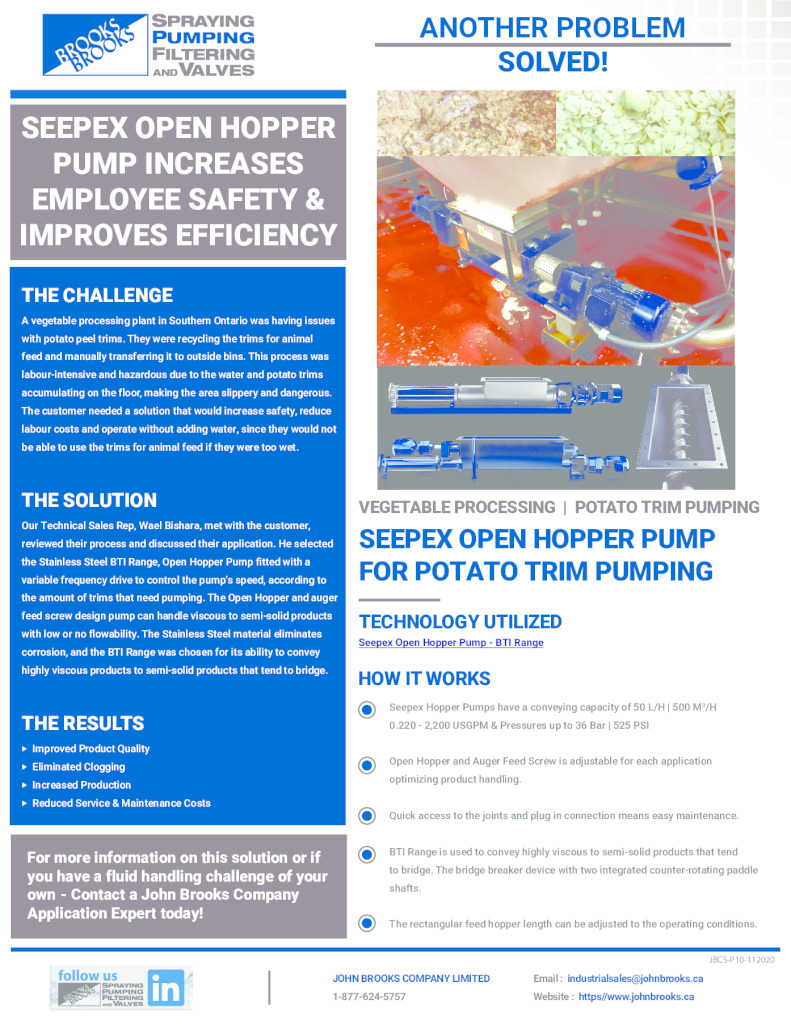

Our Technical Sales Rep, Wael Bishara, met with the customer, reviewed their process and discussed their application. He selected the Stainless Steel BTI Range, Open Hopper Pump fitted with a variable frequency drive to control the pump’s speed, according to the amount of trims that need pumping. The Open Hopper and auger feed screw design pump can handle viscous to semi-solid products with low or no flowability. The Stainless Steel material eliminates corrosion, and the BTI Range was chosen for its ability to convey highly viscous products to semi-solid products that tend to bridge.

The Results:

- Improved Product Quality

- Eliminated Clogging

- Increased Production

- Reduced Service & Maintenance Cost

Technology Used:

SEEPEX T – Open Hopper Pumps

SEEPEX T – OPEN HOPPER PUMPS SEEPEX T Open Hopper Pumps handle viscous...

How it Works:

- Seepex Hopper Pumps have

- a conveying capacity of 50 L/H | 500 M3/H

- 0.220 – 2,200 USGPM

- Pressures up to 36 Bar | 525 PSI

- Open Hopper and Auger Feed Screw is adjustable for each application optimizing product handling.

- Quick access to the joints and plug in connection means easy maintenance.

- BTI Range is used to convey highly viscous to semi-solid products that tend to bridge. The bridge breaker device with two integrated counter-rotating paddle shafts.

- The rectangular feed hopper length can be adjusted to the operating conditions.

For more information on this solution or if you have a fluid handling challenge of your own – Contact a John Brooks Company Application Expert today!