SANDPIPER SA1 Metallic Heavy Duty Flap Valve Pumps are recommended for abrasive slurries, suspended and non-suspended solids and line-size solids requirements. All SANDPIPER® Heavy Duty Flap Valve Pumps are configured in bottom discharge porting arrangements and provide superior suction lift. Heavy Duty Flap Valve Pumps are thick wall constructed of Sand-Cast Aluminum, Cast Iron and Stainless Steel with elastomer, and TPE (thermal plastic elastomers) options in diaphragms and check valves. HDF pumps are enhanced with an extended wear package.

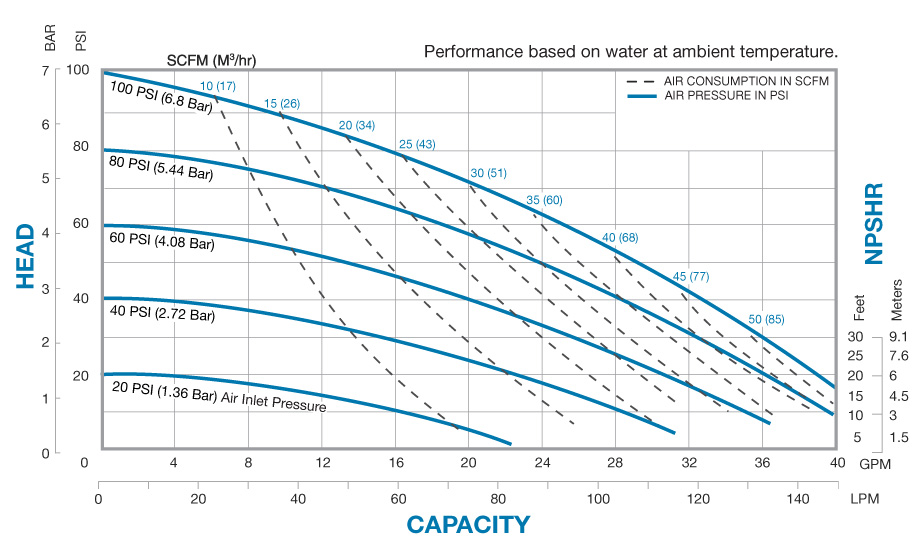

SANDPIPER SA1 Metallic – Performance Curve

SANDPIPER SA1 Metallic – Specifications

|

Port Size :

|

SA1: 1” NPT

SA25: 1″ BSP (Tapered)

|

| Capacity : |

0 to 42 gpm (159 lpm)

|

|

Air Distribution Valve :

|

No-lube, no-stall design

|

|

Solids-Handling :

|

Up to 1″ (25.4 mm)

|

|

Heads Up To:

|

125 psi or 289 ft. of water (8.6 bar or 88 meters)

|

|

Displacement/Stroke :

|

.10 gallons (.38 liters)

|

|

Max Operating Pressure :

|

125 psi (8.6 bar)

|

|

Shipping Weight :

|

Aluminum: 48 lbs. (21 kg)

Cast Iron: 76 lbs. (34 kg)

Stainless Steel: 79 lbs. (36 kg)

|

Features and Benefits of the Heavy Duty Flap Valve Pumps

SA1 BENEFITS

SA1 heavy-duty flap valve AODD pumps are:

- Recommended for abrasive slurries, suspended and non-suspended solids and line-size solids.

- Are configured with bottom discharge porting to prevent settling solids from shortening pump life and provide superior suction lift.

- Are thick-wall constructed of sand-casted aluminum, cast iron and stainless steel with elastomer and TPE (thermoplastic elastomer) diaphragms and check valves. See tabs below for a complete description.

SA1 HAS EXTERNALLY SERVICEABLE AIR DISTRIBUTION SYSTEM

When dirty air enters an AODD pump, it will require frequent servicing of the air distribution system. SANDPIPER is the only AODD pump manufacturer to offer an externally serviceable air distribution system (ESADS+), which allows complete access to the main air and pilot valves without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors), reducing your downtime by as much as 90%.