SANDPIPER S30 Non-Metallic Standard Duty AODD Ball Valve Pumps are ideally suited for intermittent, on-demand, portable, moderately abrasive fluids, and suspended solids. Standard duty pumps are constructed in Aluminum, Cast Iron, Stainless Steel and non-metallic materials such as PTFE, Polypropylene, and PVDF with Elastomer TPE (thermal plastic elastomers) and PTFE options in diaphragms and check valves.

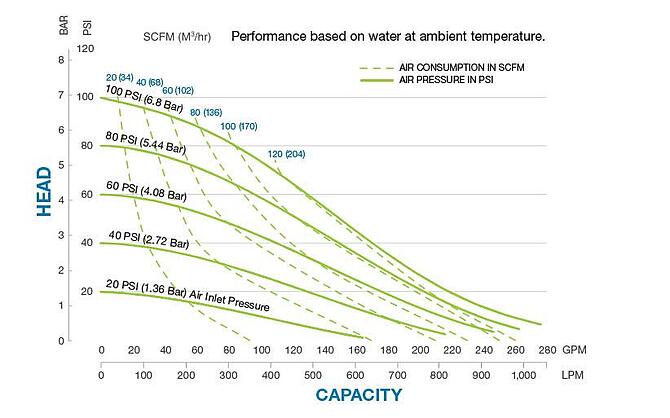

SANDPIPER S30 Non-Metallic – Performance Curve

SANDPIPER S30 Non-Metallic – Specifications

|

Port Size :

|

3″ ANSI Flange or 80mm DIN Flange

|

| Capacity : |

0 to 280 gpm (1,060 lpm)

|

|

Air Distribution Valve :

|

No-lube, no-stall design

|

|

Solids-Handling :

|

Up to ¾” (19 mm)

|

|

Heads Up To:

|

100 psi or 231 ft of water (7 bar or 70 meters)

|

|

Displacement/Stroke :

|

1.0 gallon (3.8 liters)

|

|

Max Operating Pressure :

|

100 psi (7 bar)

|

|

Shipping Weight :

|

Polypropylene:165 lbs. (75 kg)

PVDF: 271 lbs (123 kg)

|

Features and Benefits of the Standard Duty Ball Valve Pumps

- Available in corrosion-resistant polypropylene or PVDF

- Class-leading maximum flow rate and efficiency

- ESADS+ air distribution system: the only pump in its class with an externally serviceable air distribution system (see below)

- Bolted construction with stainless steel fastenersServiceability: The air distribution system (ADS) is one of the most frequently serviced parts of any AODD pump. Only SANDPIPER’s ESADS+ feature allows access to the complete ADS without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors).Simplicity: SANDPIPER’S original ADS is fully interchangeable, repairable and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership.