SANDPIPER HDF2 Metallic Heavy Duty Flap Valve Pumps are recommended for abrasive slurries, suspended and non-suspended solids and line-size solids requirements. All SANDPIPER® Heavy Duty Flap Valve Pumps are configured in bottom discharge porting arrangements and provide superior suction lift. Heavy Duty Flap Valve Pumps are thick wall constructed of Sand-Cast Aluminum, Cast Iron and Stainless Steel with elastomer, and TPE (thermal plastic elastomers) options in diaphragms and check valves. HDF pumps are enhanced with an extended wear package.

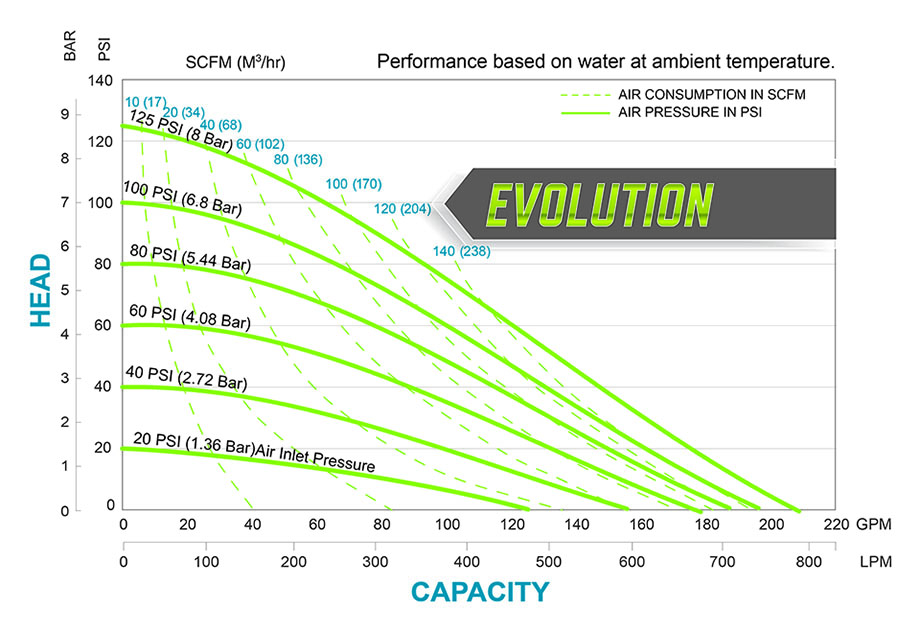

SANDPIPER HDF2 Metallic – Performance Curve

SANDPIPER HDF2 Metallic – Specifications

|

Port Size :

|

2″ NPT

|

| Capacity : |

0 to 208 gpm (787 lpm)

|

|

Air Distribution Valve :

|

No-lube, no-stall design

|

|

Solids-Handling :

|

Up to 2″ (50 mm)

|

|

Heads Up To:

|

125 psi or 289 ft. of water (8.6 bar or 88 meters)

|

|

Displacement/Stroke :

|

0.47 gallons (1.8 liters)

|

|

Max Operating Pressure :

|

125 psi (8.6 bar)

|

|

Shipping Weight :

|

Aluminum: 86 lbs. (39 kg.)

Cast Iron: 168 lbs. (76 kg)

Stainless Steel: 168 lbs. (76 kg)

|

Features and Benefits of the Heavy Duty Flap Valve Pumps

- Port size: 2″ NPT/BSP

- Capacity: 0 to 208 gpm (787 lpm)

- Suction lifts: up to 24 ft

- Air distribution valve: no-lube, no-stall externally serviceable air distribution system (ESADS+) design

- Solids handling: up to 2″ (50 mm)

- Heads: up to 125 psi or 289 ft of water (8.6 bar or 88 meters)

- Max operating pressure: 125 psi (8.6 bar)

The HDF2 pump has been optimized for performance as part of the SANDPIPER Evolution portfolio improvement. This efficient pump experienced a 49% flow rate increase, with a new maximum flow rate of up to 208 gpm (788 lpm).