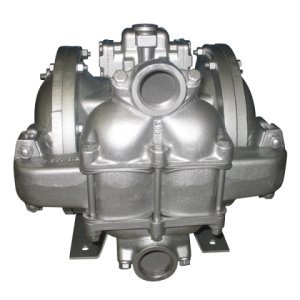

SANDPIPER HDB15 Metallic Heavy Duty Ball Valve Pumps are ideal for thin to highly viscous and small solids-laden fluids, while providing excellent suction lift capability and exclusive variable porting options (side, top, bottom and dual). Heavy Duty Ball Valve pumps are thick wall constructed of Sand Casted Aluminum, Cast Iron, Stainless Steel or Alloy C with elastomer, TPE (thermal plastic elastomers) and PTFE options in diaphragms and check valves. Heavy Duty Ball Valve pumps are enhanced with an extended wear package.

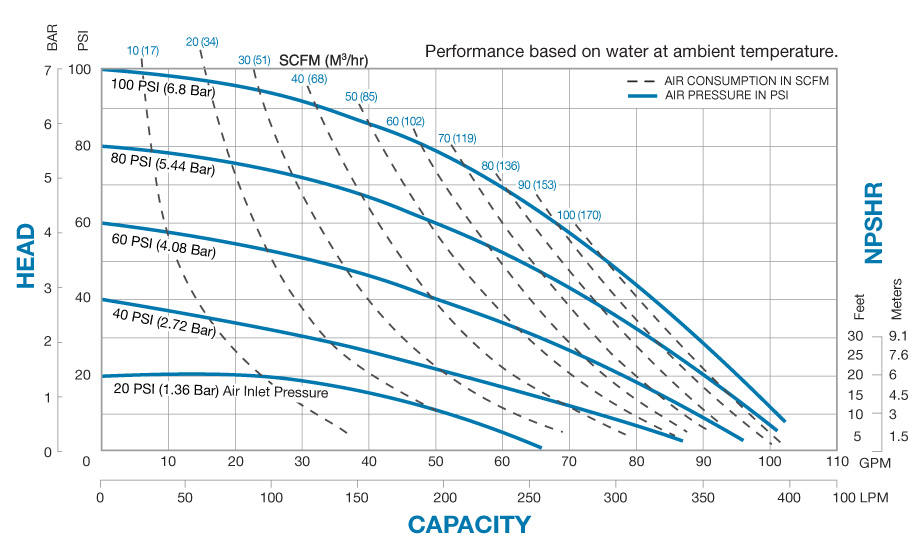

SANDPIPER HDB15 Metallic – Performance Curve

SANDPIPER HDB15 Metallic – Specifications

|

Port Size :

|

SB1: 1” NPT

SB25: 1” BSP (Tapered)

|

| Capacity : |

0 to 42 gpm (159 lpm)

|

|

Air Distribution Valve :

|

No-lube, no-stall design

|

|

Solids-Handling :

|

Up to .25″ (6.3 mm)

|

|

Heads Up To:

|

125 psi or 289 ft. of water (8.6 bar or 88 meters)

|

|

Displacement/Stroke :

|

.09 gallons (.34 liters)

|

|

Max Operating Pressure :

|

125 psi (8.6 bar)

|

|

Shipping Weight :

|

Aluminum: 31 lbs. (14 kg)

Stainless Steel: 45 lbs. (20 kg)

Alloy C: 45 lbs. (20 kg)

Stainless Steel with Cast Iron Center: 65 lbs. (30 kg)

Alloy C with Cast Iron Center: 65 lbs. (30 kg)

|

Features and Benefits of the Heavy Duty Ball Valve Pumps

- Light Weight & Portable – Weights as low as 31 lbs (14 kg).

- All Bolted Construction – Durable & High Pressure Capable

- Bottom or Top Discharge – For Pumping Out of Tough Areas

- Ball Check Valves – Provides Powerful, High Flow Pumping

- Diaphragm Connecting Rods – Reliable and Consistent Diaphragm Control

- ESADS + Plus Air Valve – Externally Serviceable Air Distribution System

- Dynamic Manifold Connections – Can be Vertically or Horizontally Mounted

- Certifications Available – CE, ATEX and ABS