Price Pump Mag-Drive Pumps Models including: HPMD; 2MS75MD; CDMD; CL150MD; XLMD and XTMD

Price Pump Mag-Drive Pumps are ideal for any application that requires leak-free pumping, high reliability, safer operation handling hazardous or expensive fluids and low cost of operation. Price® Pump Co. is a premier manufacturer of Magnetically Driven Centrifugal pumps with over 82 years of experience who specializes in addressing the needs of custom applications for industrial and OEM users. Price Pump’s world-class engineering support, customer care and standard 2-year warranty, will provide you with a pump that meets your needs.

|

|

|

HP MAG-DRIVE65 GPM (246 LPM) See More |

2MS75 MAG-DRIVE60 GPM (227 LPM) See More |

CD MAG-DRIVE190 GPM (719 LPM) See More |

|

|

CL150 MAG-DRIVE320 GPM (1211 LPM) See More |

XL XT MAG-DRIVE400 GPM (1514 LPM) See More |

Why Choose Price Pump Mag-Drive Pumps

While magnetic drive pumps have been available for many years, the increased demand for these pumps has resulted from more stringent application requirements, advancements in magnet technology, the shortcomings of mechanical seals and legislation enactment regarding fugitive emissions.

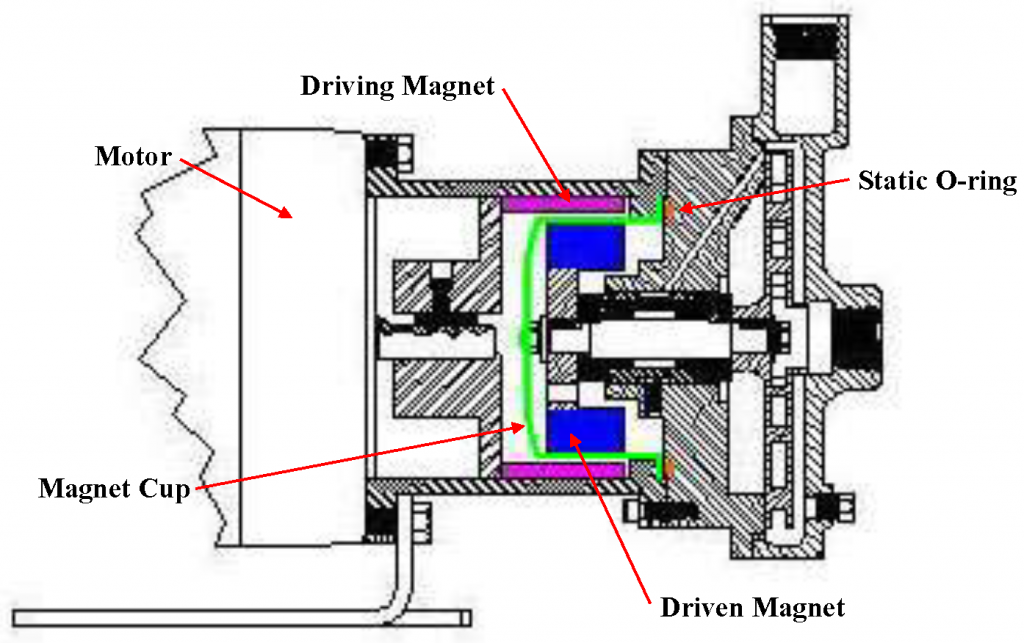

When we speak of a magnetic drive pump, we’re almost always speaking of radial aligned magnets that ‘couple’ a motor (typically electric) to a pump – see figure below.

A magnetic drive consists of three basic components:

- Driving Magnet

- Driven Magnet

- Magnet Cup (Static barrier between the magnets)

The driving magnet (connected to the motor) is radially aligned with the driven magnet (connected to the pump) with the two magnets being separated by a (non-magnetic) cup, which seals the pumped fluid from the atmosphere, typically via a static o-ring, also referred to as a hermetic seal. When the driving magnet rotates (as power is applied to the motor), the driven magnet follows (due to strong magnetic attraction) thereby turning the input shaft of the pump. A magnetic drive pump is also referred to as a ‘seal-less’ pump due to the fact that the traditional ‘mechanical seal’ is no longer utilized.

Magnetic drive pumps have many advantages with the most common being:

- Seal-less design, which eliminates potential problems with mechanical seals.

- Zero leakage / 100% emissions free.

- High reliability / Lower maintenance.

- Safer operations pumping hazardous fluids.

Seal failure, fluid or emissions leakage, and safety concerns are still primary drivers for the adoption of magnetic drive pump technology, but the increase in reliability and lower cost of ownership have become equally important reasons for their acceptance.

So, if your application requires leak-free pumping, high reliability, safer operation handling hazardous or expensive fluids and low cost of operation, you should consider a magnetic drive pump from Price Pump Company.