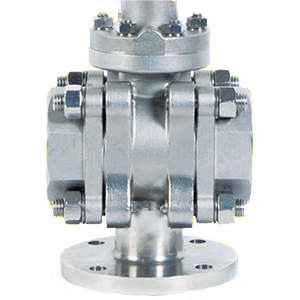

Gosco S-Class 3-Way Diverter Valve Overview

Gosco S-Class 3-Way Diverter Valves offer unrivalled quality and reliability, coupled with customization options that make them the perfect valve for your application. They are bottom entry with flow to the left or right ports and options include a Single “L” Port ball for 180° applications, and a Double “L” Port ball for 90° applications. They have all the features of a standard S-Class valve and the seats are live-loaded so they don’t rely on the process pressure to assist with sealing.

Ball Configurations

Single “L” (Looking at the ball from the top) Flow direction is bottom entry to the left. Turn 180° and flow direction is bottom entry to the right. A single “L” configuration allows you to have a shut off position at 90°.

Double “L” (Looking at the ball from the top) Flow direction is bottom entry to the left. Turn 90° and flow direction is bottom entry to the right. With a double “L” configuration, there is always flow going to one side or the other with a mix between.

Shaft Sealing System

The core of our patented shaft sealing system is the dual live-loaded packing. To eliminate side loading on the packing, we’ve added two shaft guides to support the shaft at the bottom and the top. For a third layer of protection, a fugitive emissions port can be drilled to monitor the areas between the packing sets. Our shaft sealing system has been tested by TUV, and exceeds all current and projected fugitive emission standards.

Encapsulated “Soft” Seats

Gosco S-Class encapsulated soft seats are used for high cycle, abrasive, and high pressure/temperature applications. Our proprietary live-loaded design allows us to completely encapsulate the insert on all four sides, leaving only a small section of the “Soft” material exposed for sealing. The insert is held in place with “barbs” that prevent it from extruding out of the carrier. A special fixture compresses the seat assembly to 3 times the max pressure rating of the valve, so that the insert takes a compression set. The seat profile is then machined in to the insert, and it is match lapped to the ball. For abrasive applications, it can be used in conjunction with a boronized, arcuate cut ball.

Extended Bonnet

The extended bonnet is perfect for insulated lines as there is at least 2″ between the top of the flange and the bottom of the Clearview mounting pad. This allows you to fully insulate the valve and still have access to make packing adjustments, without having to remove the actuator or insulation. The valve shaft flats are also visible, and the actuator is raised away from the elevated process temperatures, preventing damage to the actuator seals.

Clearview Mounting Pad

The Clearview mounting pad is a combination of an ISO 5211 mounting pad for easy installation of valve accessories, and a CNC machined/cast bracket that guarantees accurate actuator alignment. Packing adjustments can be performed in-line without removing the actuator, and the double “D” shaft gives you a visible indication of the position of the valve. Clearview also raises the actuator away from the valve, and acts as a heat sink to protect it from high temperatures.

-

3-Way Valve Sizes

NPS ½ FP to NPS 16 SP

½″ FP to 16″ SP -

3-Way Valve Connections

150# to 4500#, NPT, SW,

BW, Graylock and Custom -

3-Way Valve Applications

Low temperatures, exotic

alloys, and custom designs -

3-Way Valve Temperatures

-50°C to 260°C

-58°F to 500°F