EATON Y Strainers are a cost-effective solution for the mechanical removal of unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

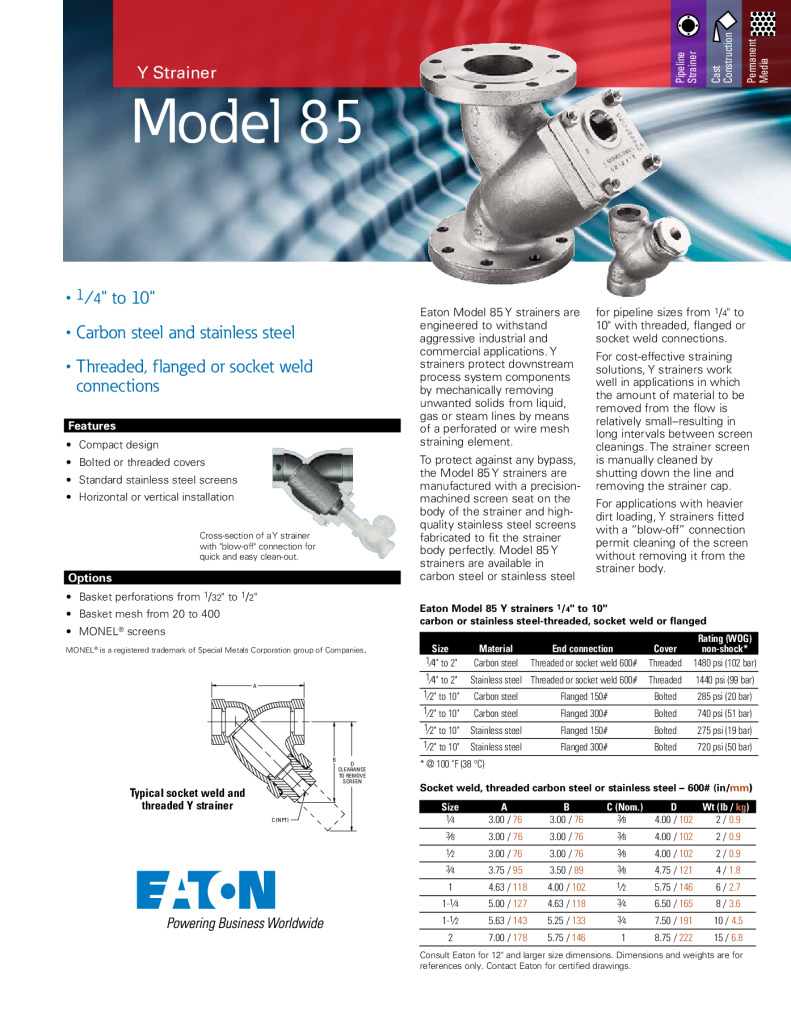

EATON Y Strainers Carbon Steel and Stainless Steel – Threaded, Flanged and Socket Welded, 1/4″ to 10″

EATON Y Strainers are typically used in applications where the amount of solids to be removed is small, and where frequent clean-out is not required. They are most often installed in gaseous services such as steam, air, nitrogen, natural gas, etc. The compact, cylindrical shape of the Y-strainer is very strong and can readily accommodate the high pressures that are common in this type of service. Pressures up to 6000 psi are not unusual. When steam is being handled, high temperature can be an additional complicating factor. A steam pressure of 1500 psi will often be found at temperatures of 1000°F.

EATON Y Strainers have the advantage of being able to be installed in either a horizontal or vertical position. However, in both cases, the screening element or “leg” must be on the “downside” of the strainer body so the entrapped solids can be properly collected and held for disposal. Eaton heavy-duty Model 85 Y Strainers are furnished with high quality stainless steel screens that are carefully fabricated to fit the strainer body perfectly. This, coupled with the precision machined screen seat on the body of the strainer, protects against any bypass.

Features

- Heavy Duty Construction

- Compact design

- Bolted or threaded covers

- Standard stainless steel screens

- Suitable for liquid, gas or steam

- Synthetic fiber gaskets

Options

- Monel screens

- Perforated stainless steel screens – 1/32” to ½”

- 20, 40, 60, 80, 100, 150, 200, 325 and 400 mesh stainless steel screens