EATON TS Vertical Gas Liquid In-Line Separators, formerly Wright Austin, with its cost effective design, is the vertical separator of choice for most applications that require clean, dry air, gas, or steam.

EATON TS Vertical Gas Liquid In-Line Separators Features

- Available from 1” to 24” in carbon steel or cast stainless steel construction sizes

- Designed for high liquid loading applications

- High efficiency over wide flow range

- When properly sized, installed, and drained, will remove up to 99% of all liquid and solid entrainment where particle size exceeds 10 microns

- No moving parts to wear out, no required maintenance

- Exclusive Vortex Containment Plate (VCP) System

EATON TS Vertical Gas Liquid In-Line Separators Options

- ASME UM or U code stamp

- Support legs

- Custom fabrication to fit exact requirements of applications requiring unique sizes or piping connections, or where weight is a concern

Exclusive Design

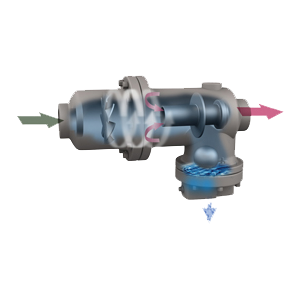

Centrifugal downward motion deflects moisture-laden gas as it enters the inlet of the separator. The entrained solids and moisture droplets separate from the gas by a reduction in velocity. Separated liquid and solids fall into a reservoir where Eaton’s exclusive Vortex Containment Plate (VCP) ensures that they cannot be re-entrained. The Vortex Containment Plate then directs the clean, dry flow to the outlet. The VCP eliminates the need for expensive, delicate baffles used in ordinary separators.

Vortex Containment Plate

Moisture laden gas enters the inlet of the separator where it is deflected by Eaton’s unique Cenpellar™ into a centrifugal motion. The entrained solids and moisture droplets are separated out by a reduction in velocity. Separated liquid and solids fall into the separators integral drain trap where Eaton’s exclusive Vortex Containment Plate (VCP) ensures that they cannot be re-entrained. The VCP is constructed with a series of carefully placed rings and plates that shield the separated liquid from the vortex action within the separator to prevent re-entrainment . The VCP also helps direct the liquid to the drain trap while at the same time moves the clean, dry gas to the separator outlet. With Eaton’s exclusive VCP the need for expensive, delicate baffles that are used in ordinary separators is eliminated.

Maintenance and Spare Parts

Eaton separators have no moving parts. All components are either bolted or welded into place. Therefore parts lists are not available. The separators are bolted, threaded, or welded into the lines. They are self-cleaning, and do not need lubrication or maintenance. For this reason, lubricating, operating and maintenance manuals are not available.

EATON TS Vertical Gas Liquid In-Line Separators Applications

- Steam drums

- Steam turbines

- Intercooler equipment

- Aftercooler equipment

- Gas well heads

- Deep well heads

- Oil extraction

- Chemical processing

- Scrubbing systems

- Evaporator

- Glycol dehydration

- Sulfur condenser

- Mist elimination

- Heat exchangers

- Reactors

- Landfill/waste gas