Dollinger precision-engineered air intakes, fuel/oil filtration packages and oil exhaust eliminators are products you can depend on. Our customers have much invested in their hi-speed turbo compressors, turbines and blowers. That is why you’ll find these systems protecting critical air intake, fuel and lubrication systems around the world. When shaft speeds approach 70,000 rpm and environments range from arctic snow to desert sands, Dollinger quality and performance helps everyone breathe easier.

|

Dollinger Air Intake FiltersContaminants at the intake of compressors, blowers and turbines dramatically affect the cost of supplying compressed air. Inefficient intake filtration permits contaminants to corrode, erode and foul internals. Dollinger air intake filters will deliver optimum performance, energy savings and protection to gain long component service life. |

|---|---|

|

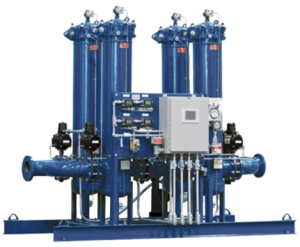

In-Line FiltrationAir Gas and Liquid Pipeline – High performance in-line filtration products are designed to selectively target & remove unwanted contaminants like dirt, rust, pipe scale, oil and water. Unlike conventional multiple-cartridge filters, the Dollinger Element Design Concept maximizes the effective filtration area for a given vessel size resulting in lower differential pressure and extended service life. In addition to the standard range of filters, Dollinger is able to offer customized filter designs and capacities to suit the particular process / application demands of the customer. |

|

Filter ElementsA wide range of filter media Panel and Radial Fin with components including: natural and synthetic materials, PTFE, cotton and stainless steel. Dollinger offers an extensive range of synthetic and natural fiber filter media suitable for use in most processes. In addition, stainless steel mesh media can be incorporated in the existing element design for more demanding applications. In most instances the Dollinger filter element can be cleaned and reused many times. This feature is especially beneficial in applications having high levels of contaminant. |

|

Dollinger Oil Exhaust Filters – Oil Mist EliminatorsDesigned to recover fugitive oil mist emissions to lower operating costs, promote good health and improve safety. Large high speed rotation equipment such as gas turbines, steam turbines, axial and centrifugal compressors, requires a large volume of oil for lubrication, cooling, and sealing of the bearings. The lubricating oil can be either mineral based or synthetic. The Dollinger Oil Mist Filter Eliminator is a filtration system of superior efficiency – it collects 99.97% of oil droplets 0.3 micron and larger, thus removing virtually 100% of oil mist emissions. This performance places Dollinger at the very forefront of oil mist elimination technology. |