Custom Spray Nozzle Solutions – Venturi Scrubbing Doubling Capacity

Application #060800

Industry: Pollution Control

Application: Venturi Scrubbing

Product Description: Special Bete SpiralAir Lance

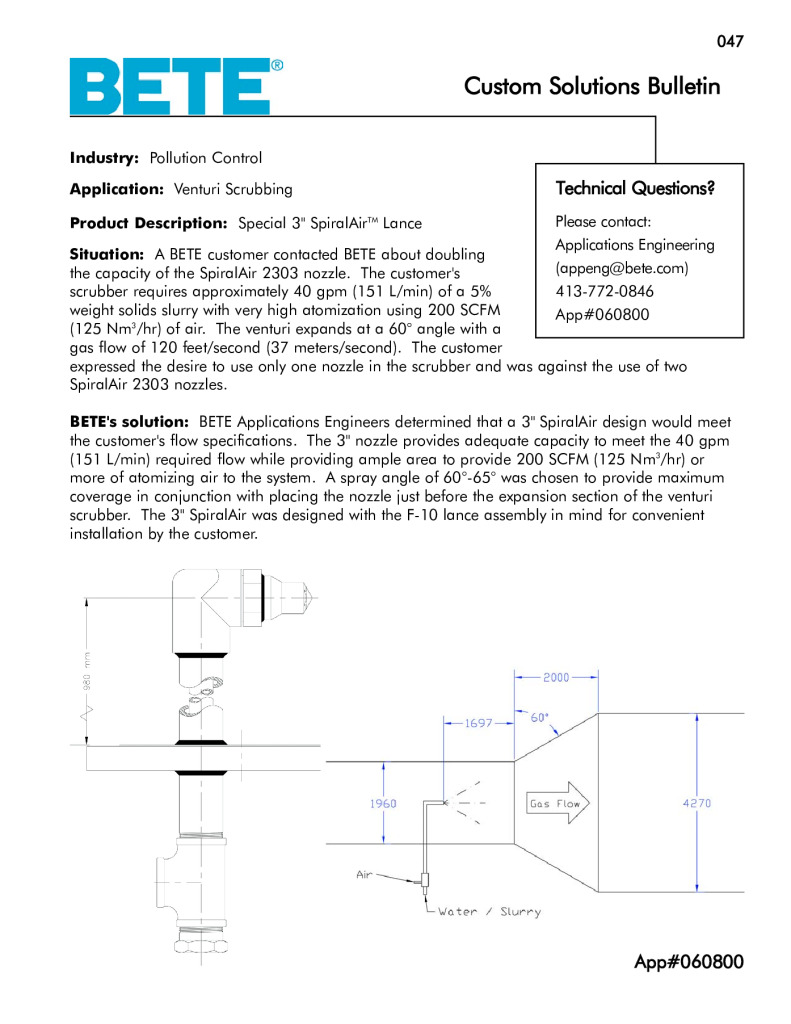

Situation: A Bete customer contacted Bete about doubling the capacity of the SpiralAir 2303 nozzle. The customer’s scrubber requires approximately 40 gpm (151 L/min) of a 5% weight solids slurry with very high atomization using 200 SCFM (125 Nm³/hr) of air. The venturi expands at a 60° angle with a gas flow of 120 feet/second (37 meters/second). The customer expressed the desire to use only one nozzle in the scrubber and was against the use of two SpiralAir 2303 nozzles.

Solution: Bete Applications Engineers determined that a 3″ SpiralAir spray nozzle design would meet the customer’s flow specifications. The 3″ nozzle provides adequate capacity to meet the 40 gpm (151 L/min) required flow while providing ample area to provide 200 SCFM (125 Nm³/hr) or more of atomizing air to the system. A spray angle of 60°-65° was chosen to provide maximum coverage in conjunction with placing the nozzle just before the expansion section of the venturi scrubber. The 3″ SpiralAir was designed with the F-10 lance assembly in mind for convenient installation by the customer.

Custom Spray Nozzle Solutions – Venturi Scrubbing Doubling CapacityDrawing and Pictures: