Custom Spray Nozzle Solutions – Tote Cleaning

Application #080805

Industry: Manufacturing – Paint

Application: Tote Cleaning

Product Description: 3/4″ Bete HydroWhirl S40

Situation: A manufacturer of primer paint called Bete regarding cleaning 350-gallon totes (or Intermediate Bulk Containers). Their current cleaning process took around two hours and used 10-15 gallons of solvent. Because the solvent produces fumes that are an explosion hazard, any cleaning nozzles with moving parts must operate in a way that would not create an ignition of this gas.

Solution: The Bete HydroWhirl S 40 was selected for its increased spray impact force and its ATEX certification. The ATEX certification states that the HydroWhirl S40 is safe to use in explosive environments. The use of the HydroWhirl S40 reduced the cleaning time to 1 hour and the amount of solvent needed to 7 gallons.

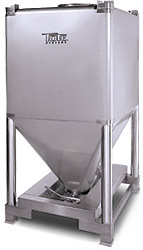

Background: Intermediate Bulk Containers

Intermediate Bulk Containers (IBCs) are product transport units made in a variety of shapes, materials, and styles. The most common sizes would be about 1 m3 but can be as large as 3 m3. The product stored in IBCs ranges from solids (grains, powders, frozen food) to liquids (chemicals, liquid food stuffs, glue) as well as other large products such as car part or flanges. IBCs are designed to be easily transported, which in many cases means features such as built in access for fork lifts, being easily stackable, and durable enough for reuse.

Overview of IBC cleaning and special considerations for cleaning nozzles:

There are four steps to a standard IBC cleaning process. The first step is a water rinse to remove dirt and dust, followed by a detergent wash. Then there is a final rinse to remove the detergent and the final step is an air dry. There are several types of IBC washing machines that range from simple drop-in set-ups to stationary machines, which are like IBC dishwashers or booth type. The IBC is placed in the machine that inserts a spray device into the IBC and washes, drains, and dries the IBC.

The typical size range of IBC for which the HydroWhirl would be applicable:

The HydroWhirl tank wash line is equipped to handle tanks up to 19ft in diameter. Most IBCs have diameters or widths around 3ft, therefore there is a HydroWhirl nozzle for nearly every size of IBC. The HydroWhirls recommended most for IBC cleaning are the HWS30, HWS40, HWRB30, and HWRB40.

Types of materials/industries that use IBCs:

The types of items stored in IBCs range from liquid chemicals to automotive parts. A manufacturer that is producing a product that easier to store (and/or move) in an IBC than it is to store on its own would use IBCs. BETE’s manufacturing and shipping departments uses simplified IBCs in the transport of smaller nozzles from one department to the next as well as storage in inventory.

Which applications are likely to be cleaned with HydroWhirl?

BETE HydroWhirl nozzles are best suited for dusts, powders, liquids, loosely caked on materials, and possibly some hardened substances. Most hardened substances would be reserved for the jet type tank washing nozzles. Obviously, the HydroWhirl would not be suited for chemicals that would react negatively with 316L SS. However, these applications may be an opening for HydroWhirl nozzles in Hastelloy.

Custom Spray Nozzle Solutions – Tote Cleaning Drawings and Sketches: