Custom Spray Nozzle Solutions – Specialized Gas Scrubbing Process

Application #040881

Industry: Refining

Application: Other Scrubbing

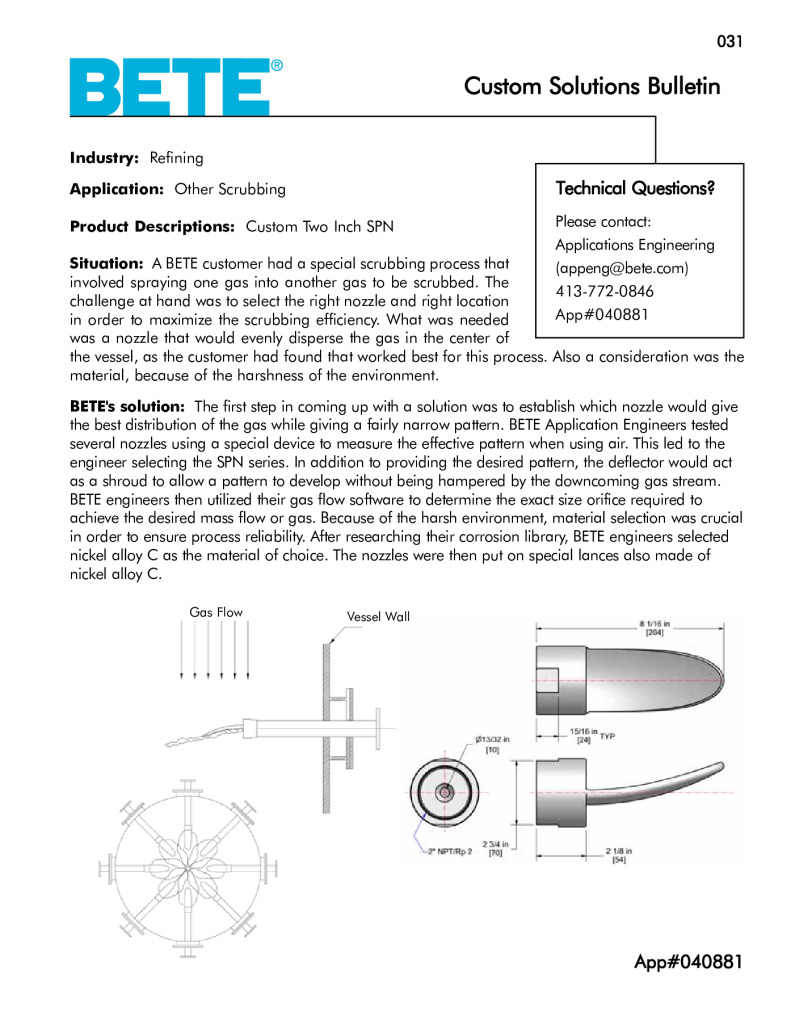

Product Description: Custom Two Inch Bete SPN

Situation: A Bete customer had a special scrubbing process that involved spraying one gas into another gas to be scrubbed. The challenge at hand was to select the right nozzle and right location in order to maximize the scrubbing efficiency. What was needed was a nozzle that would evenly disperse the gas in the center of the vessel, as the customer had found that worked best for this process. Also a consideration was the material, because of the harshness of the environment.

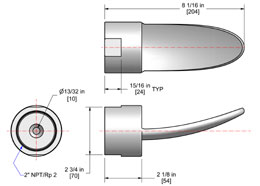

Solution: The first step in coming up with a solution was to establish which nozzle would give the best distribution of the gas while giving a fairly narrow pattern. Bete Application Engineers tested several nozzles using a special device to measure the effective pattern when using air. This led to the engineer selecting the SPN series. In addition to providing the desired pattern, the deflector would act as a shroud to allow a pattern to develop without being hampered by the downcoming gas stream. Bete engineers then utilized their gas flow software to determine the exact size orifice required to achieve the desired mass flow or gas. Because of the harsh environment, material selection was crucial in order to ensure process reliability. After researching their corrosion library, Bete engineers selected nickel alloy C as the material of choice. The nozzles were then put on special lances also made of nickel alloy C.

Custom Spray Nozzle Solutions – Specialized Gas Scrubbing Process Drawings and Sketches: