Custom Spray Nozzle Solutions – Pond Cooling in Food Processing Industry

Application #091869

Industry: Food Processing

Application: Pond Cooling

Product Description: Bete TH Nozzles with Junction Boxes

Situation: A distiller of rum needed to cool process water in their distillery. They wanted to construct a cooling pond with a total capacity of 1760 gpm (6662 L/min) and had an available pressure of 7.5 psi (0.52 bar). The customer wanted to use right angle tangential nozzles because of their large free passage.

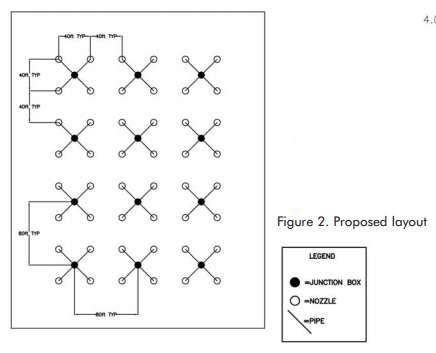

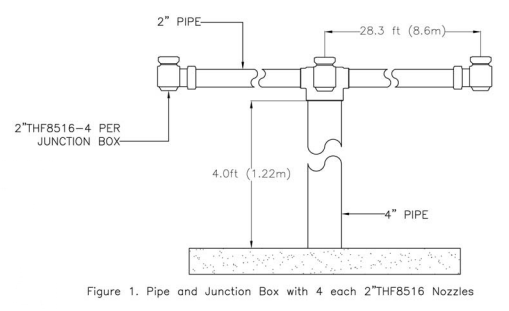

Solution: Using the Bete estimated trajectory program, Applications Engineering was able to estimate the coverage of a 2″THF8516 spraying upward at 7.5 psi to be approximately a 40′ (6.1 m) diameter. This meant that the nozzle spacing would need to be 40′ (6.1 m) to prevent the patterns from overlapping. Using 12 junction boxes with 4 nozzles each arranged as shown, worked out to a 6 x 8 nozzle array. Because clean water was being sprayed, brass was chosen as the material of construction for economic reasons.

Custom Spray Nozzle Solutions – Pond Cooling in Food Processing Industry Drawings and Sketches: