Custom Spray Nozzle Solutions – Poaching Meat with Steam

Application #091169

Industry: Food Processing

Application: Poaching Meat with Steam

Product Description: ½” Bete WL Full Cone Whirl Nozzles

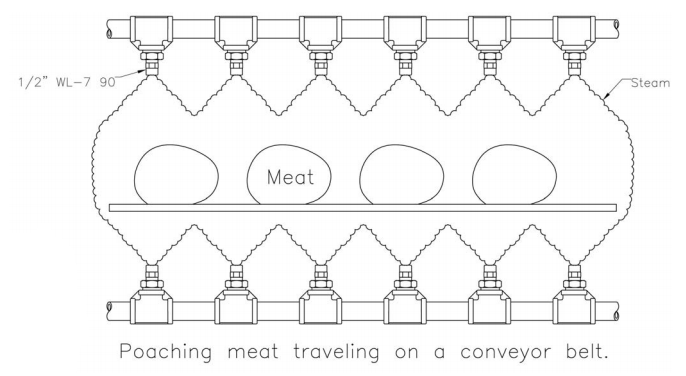

Situation: A Bete customer had large spiral oven in which meat is poached. The goal was to inject 1800 lb/hr (816.5 kg/hr) of steam at 60 psi (4.1 bar). The steam was to be sprayed from nozzles located above and below the meat. The meat would be traveling on a wire mesh conveyor belt through the oven.

Solution: Using proprietary software, Bete can estimate flow rates of various gases through a nozzle. The calculations take in to account vessel pressure, gas pressure, and gas temperature. Using the software, it was determined that twelve (12) ½” WL-7 90 nozzles made in 316 stainless steel would be enough to provide full coverage of the top and bottom of the belt and meet the required steam flow rate. Six (6) nozzles will be placed above the belt and six (6) nozzles will be placed underneath the belt. Bete also supplies clean-in-place nozzles for ovens of this type.

Custom Spray Nozzle Solutions – Poaching Meat with Steam Drawings and Sketches: