Custom Spray Nozzle Solutions – Oil Quench in Ethylene Process

Application #071602

Industry: Refining/Chemical Processing

Application: Oil Quench in Ethylene Process

Product Description: Bete MaxiPass 1000N Lance

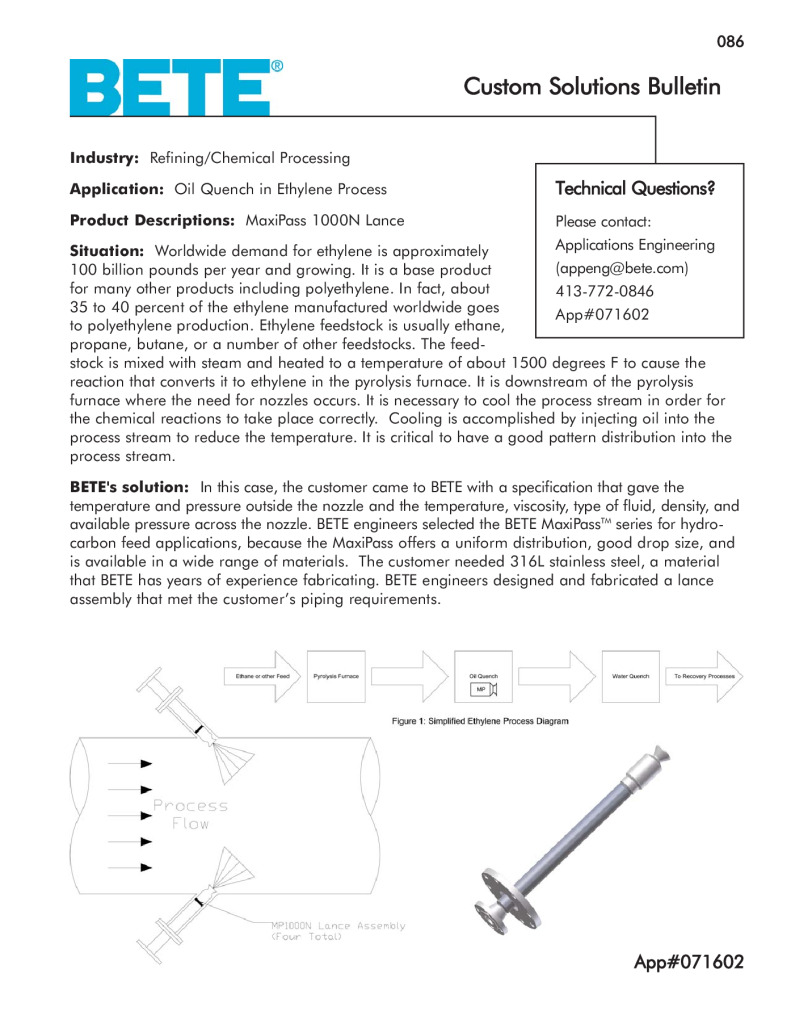

Situation: Worldwide demand for ethylene is approximately 100 billion pounds per year and growing. It is a base product for many other products including polyethylene. In fact, about 35 to 40 percent of the ethylene manufactured worldwide goes to polyethylene production. Ethylene feedstock is usually ethane, propane, butane, or a number of other feedstocks. The feedstock is mixed with steam and heated to a temperature of about 1500°F to cause the reaction that converts it to ethylene in the pyrolysis furnace. It is downstream of the pyrolysis furnace where the need for nozzles occurs. It is necessary to cool the process stream in order for the chemical reactions to take place correctly. Cooling is accomplished by injecting oil into the process stream to reduce the temperature. It is critical to have a good pattern distribution into the process stream.

Solution: In this case, the customer came to Bete with a specification that gave the temperature and pressure outside the nozzle and the temperature, viscosity, type of fluid, density, and available pressure across the nozzle. Bete engineers selected the Bete MaxiPass series for hydrocarbon feed applications, because the MaxiPass offers a uniform distribution, good drop size, and is available in a wide range of materials. The customer needed 316L stainless steel, a material that Bete has years of experience fabricating. Bete engineers designed and fabricated a lance assembly that met the customer’s piping requirements.

Custom Spray Nozzle Solutions – Oil Quench in Ethylene Process Drawings and Sketches: