Custom Spray Nozzle Solutions – Odor Control Scrubbing

Application #071809

Industry: Food Processing

Application: Odor Control Scrubbing

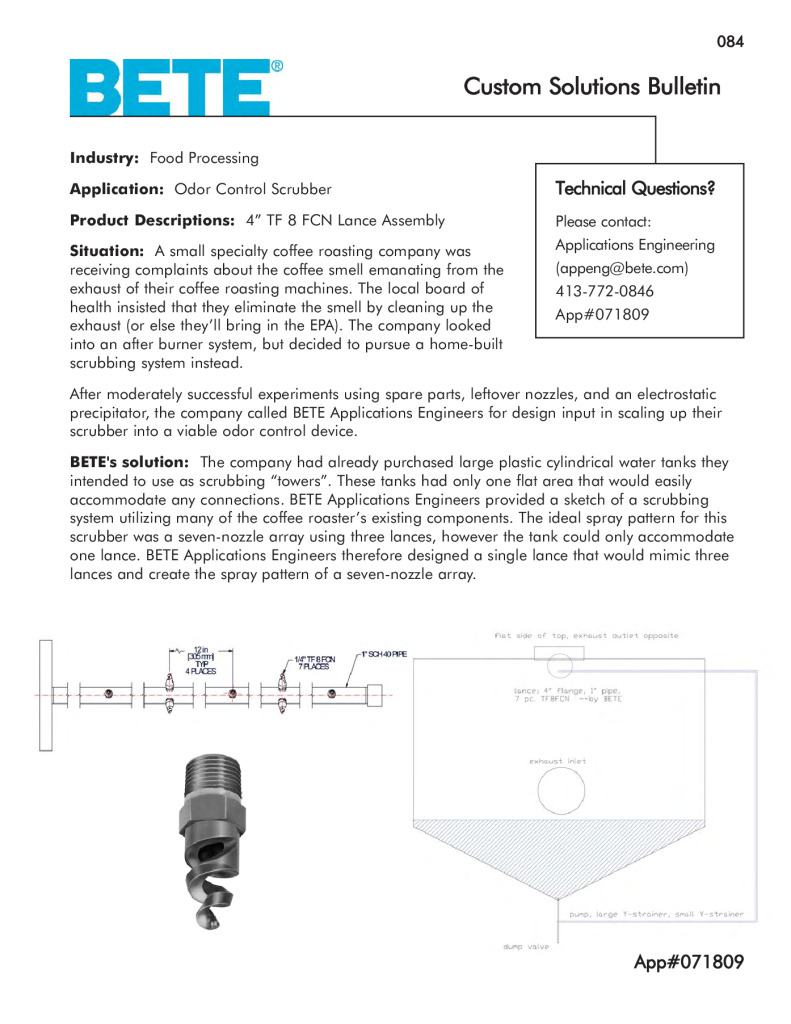

Product Description: 4″ Bete TF 8 FCN Lance Assembly

Situation: A small specialty coffee roasting company was receiving complaints about the coffee smell emanating from the exhaust of their coffee roasting machines. The local board of health insisted that they eliminate the smell by cleaning up the exhaust (or else they’ll bring in the EPA). The company looked into an after burner system, but decided to pursue a home-built scrubbing system instead. After moderately successful experiments using spare parts, leftover nozzles, and an electrostatic precipitator, the company called Bete Applications Engineers for design input in scaling up their scrubber into a viable odor control device.

Solution: The company had already purchased large plastic cylindrical water tanks they intended to use as scrubbing “towers”. These tanks had only one flat area that would easily accommodate any connections. Bete Applications Engineers provided a sketch of a scrubbing system utilizing many of the coffee roaster’s existing components. The ideal spray pattern for this scrubber was a seven-nozzle array using three lances of Bete TF nozzles, however the tank could only accommodate one lance. Bete Applications Engineers therefore designed a single lance that would mimic three lances and create the spray pattern of a seven-nozzle array.

Custom Spray Nozzle Solutions – Odor Control Scrubbing Drawings and Sketches: