Custom Spray Nozzle Solutions – Humidification of Cabinet Door Facilities

Application #041793

Industry: Wood Products

Application: Humidification of Cabinet Door Facilities

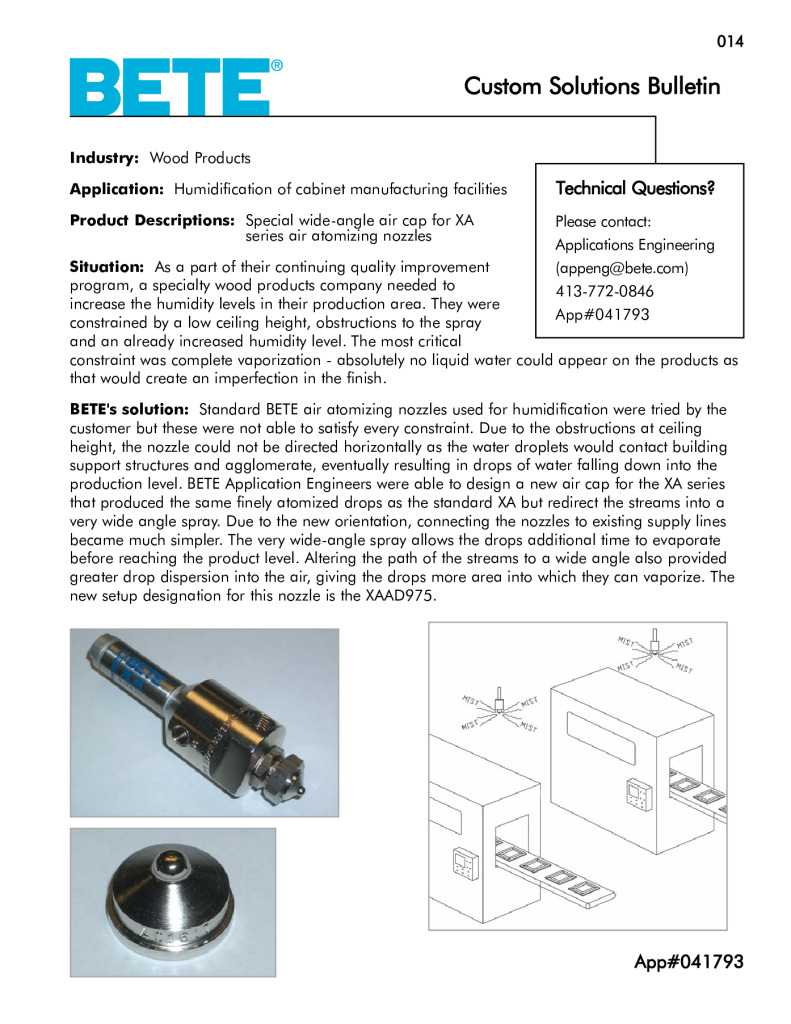

Product Description: Special wide-angle air cap for Bete XA series air atomizing nozzles

Situation: As a part of their continuing quality improvement program, a specialty wood products company needed to increase the humidity levels in their production area. They were constrained by a low ceiling height, obstructions to the spray and an already increased humidity level. The most critical constraint was complete vaporization – absolutely no liquid water could appear on the products as that would create an imperfection in the finish.

Solution: Standard Bete air atomizing nozzles used for humidification were tried by the customer but these were not able to satisfy every constraint. Due to the obstructions at ceiling height, the nozzle could not be directed horizontally as the water droplets would contact building support structures and agglomerate, eventually resulting in drops of water falling down into the production level. Bete Application Engineers were able to design a new air cap for the XA series that produced the same finely atomized drops as the standard XA but redirect the streams into a very wide angle spray. Due to the new orientation, connecting the nozzles to existing supply lines became much simpler. The very wide-angle spray allows the drops additional time to evaporate before reaching the product level. Altering the path of the streams to a wide angle also provided greater drop dispersion into the air, giving the drops more area into which they can vaporize. The new setup designation for this nozzle is the XAAD975.