Custom Spray Nozzle Solutions – High Turndown Injector

Application #041405

Industry: Utilities

Application: Injecting liquid hydrocarbon into gas stream

Product Description: High turndown injector

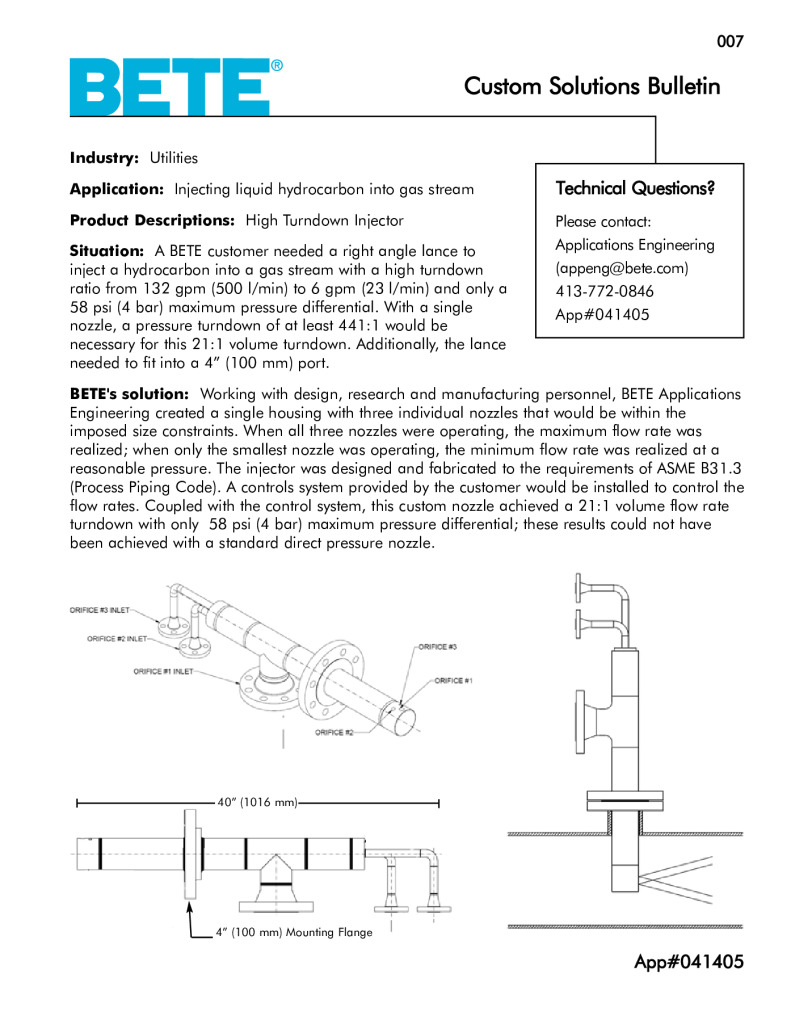

Situation: The customer needed a right angle lance to inject a hydrocarbon into a gas stream with a high turndown ratio from 132 gpm (500 L/min) to 6 gpm (23 L/min) and only a 58 psi (4 bar) maximum pressure differential. With a single nozzle, a pressure turndown of at least 441:1 would be necessary for this 21:1 volume turndown. Additionally, the lance needed to fit into a 4″ (100 mm) port.

Solution: Working with design, research and manufacturing personnel, BETE Applications Engineering created a single housing with three individual nozzles that would be within the imposed size constraints. When all three nozzles were operating, the maximum flow rate was realized; when only the smallest nozzle was operating, the minimum flow rate was realized at a reasonable pressure. The injector was designed and fabricated to the requirements of ASME B31.3 (Process Piping Code). A controls system provided by the customer would be installed to control the flow rates. Coupled with the control system, this custom nozzle achieved a 21:1 volume flow rate turndown with only 58 psi (4 bar) maximum pressure differential; these results could not have been achieved with a standard direct pressure nozzle.