Custom Spray Nozzle Solutions – Dust Suppression

Application #090368

Industry: Food Processing/Agriculture

Application: Dust Suppression

Product Description: 3/8″ TF8FCN

Situation: An offshore trading company contacted Bete Applications Engineering for advice on a dust suppression application. They had a problem with large amounts of dust being produced when sugar cane was offloaded from a truck. The trucks are unloaded from the side for fast transfer of the cane. The dust made work conditions hazardous and water in this area was limited and valuable.

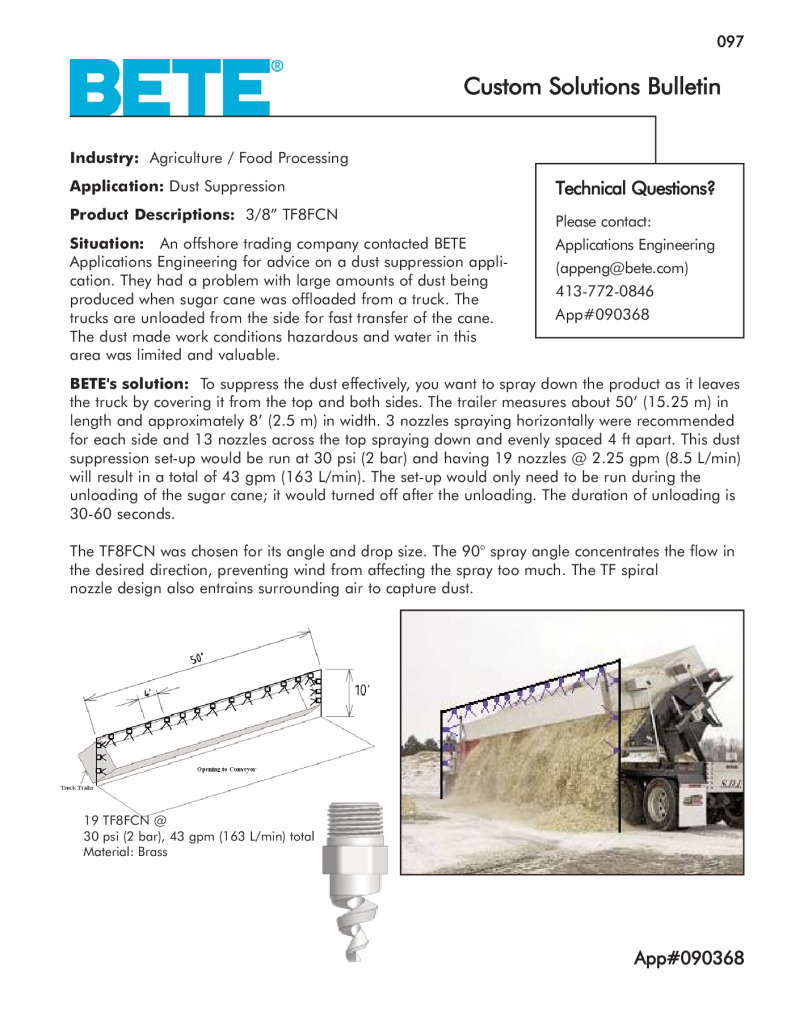

Solution: To suppress the dust effectively, you want to spray down the product as it leaves the truck by covering it from the top and both sides. The trailer measures about 50′ (15.25 m) in length and approximately 8′ (2.5 m) in width. 3 nozzles spraying horizontally were recommended for each side and 13 nozzles across the top spraying down and evenly spaced 4 ft apart. This dust suppression set-up would be run at 30 psi (2 bar) and having 19 nozzles @ 2.25 gpm (8.5 L/min) will result in a total of 43 gpm (163 L/min). The set-up would only need to be run during the unloading of the sugar cane; it would turned off after the unloading. The duration of unloading is 30-60 seconds.

The Bete TF8FCN in brass was chosen for its angle and drop size. The 90° spray angle concentrates the flow in the desired direction, preventing wind from affecting the spray too much. The TF spiral nozzle design also entrains surrounding air to capture dust.

Custom Spray Nozzle Solutions – Dust Suppression Drawings and Sketches: