Custom Spray Nozzle Solutions – Deluge Tank Cooling System

Application #090554

Industry: Chemical Processing

Application: Deluge Cooling

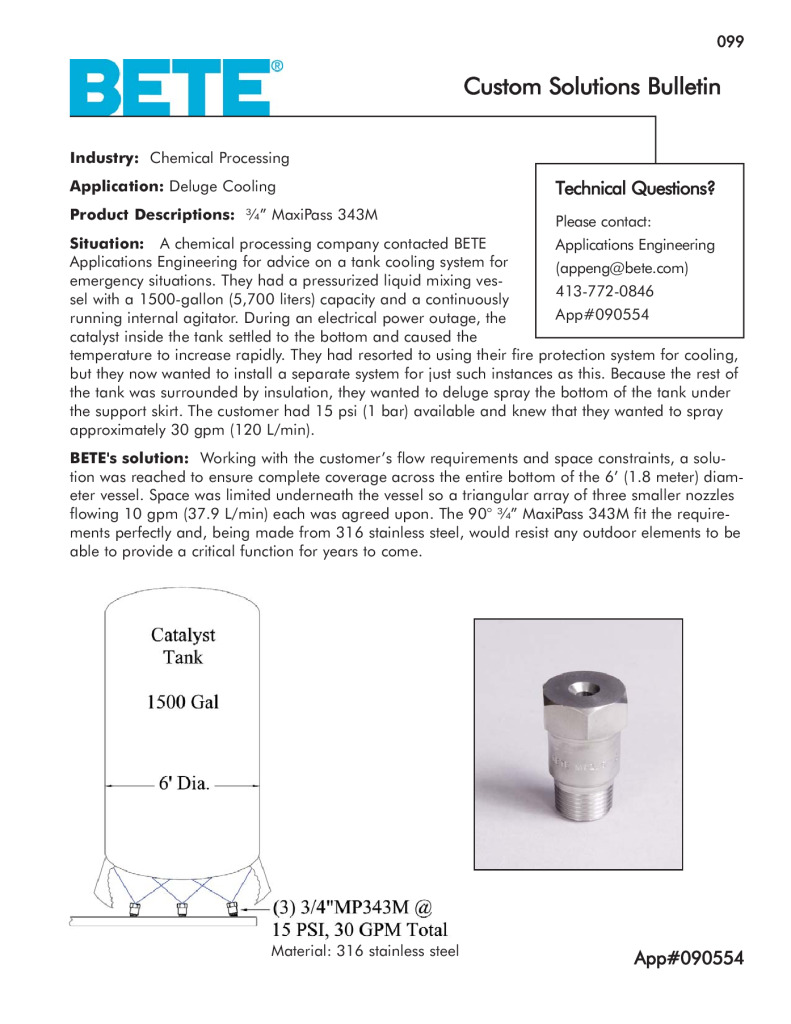

Product Description: Bete ¾” MaxiPass 343M

Situation: A chemical processing company contacted Bete Applications Engineering for advice on a tank cooling system for emergency situations. They had a pressurized liquid mixing vessel with a 1500-gallon (5,700 liters) capacity and a continuously running internal agitator. During an electrical power outage, the catalyst inside the tank settled to the bottom and caused the temperature to increase rapidly. They had resorted to using their fire protection system for cooling, but they now wanted to install a separate system for just such instances as this. Because the rest of the tank was surrounded by insulation, they wanted to deluge spray the bottom of the tank under the support skirt. The customer had 15 psi (1 bar) available and knew that they wanted to spray approximately 30 gpm (120 L/min).

Solution: Working with the customer’s flow requirements and space constraints, a solution was reached to ensure complete coverage across the entire bottom of the 6′ (1.8 m) diameter vessel. Space was limited underneath the vessel so a triangular array of three smaller nozzles flowing 10 gpm (37.9 L/min) each was agreed upon. The 90° ¾” MaxiPass343M fit the requirements perfectly and, being made from 316 stainless steel, would resist any outdoor elements to be able to provide a critical function for years to come.

Custom Spray Nozzle Solutions – Deluge Tank Cooling System Drawings and Sketches:

(3) 3/4″ MaxiPass 343M @

15 psi (1 bar), 30 gpm (120 L/min) total

Material: 316 stainless steel