Custom Spray Nozzle Solutions – Dairy Industry Swirl Units

Application #050332

Industry: Food Processing

Application: Spray Drying

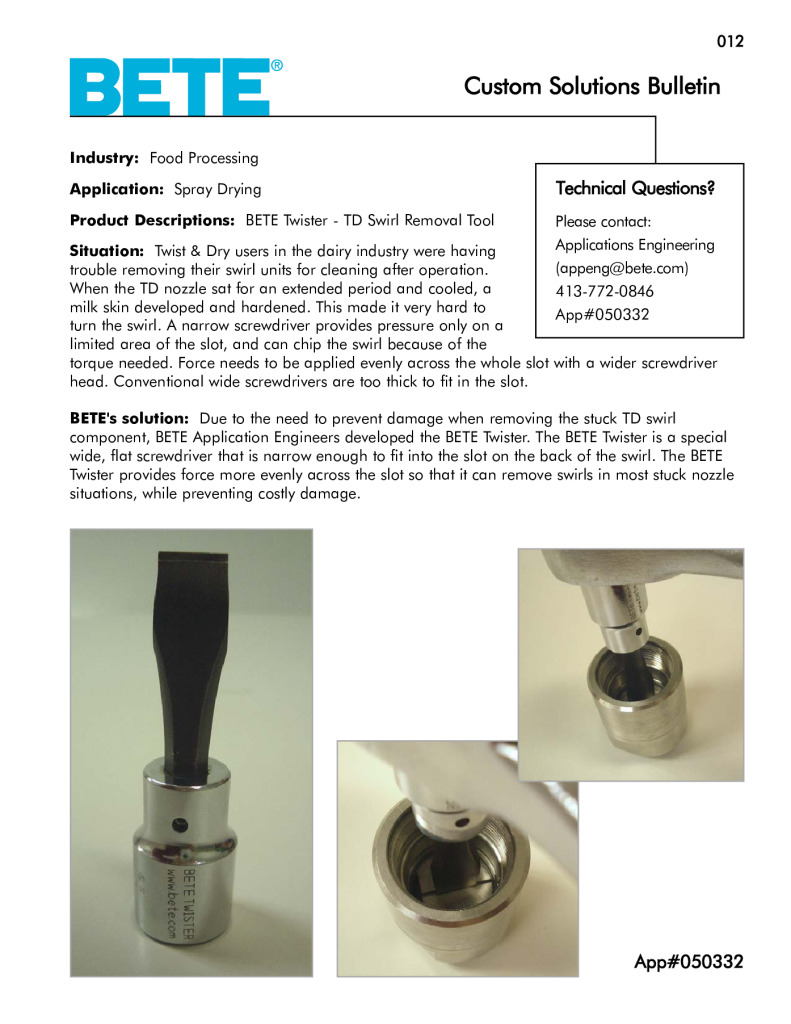

Product Description: BETE Twister – Twist & Dry (TD) Swirl Removal Tool

Situation: Twist & Dry (TD) users in the dairy industry were having trouble removing their swirl units for cleaning after operation. When the TD nozzle sat for an extended period and cooled, a milk skin developed and hardened. This made it very hard to turn the swirl. A narrow screwdriver provides pressure only on a limited area of the slot, and can chip the swirl because of the torque needed. Force needs to be applied evenly across the whole slot with a wider screwdriver head. Conventional wide screwdrivers are too thick to fit in the slot.

Solution: Due to the need to prevent damage when removing the stuck TD swirl component, Bete Application Engineers developed the Bete Twister. The Bete Twister is a special wide, flat screwdriver that is narrow enough to fit into the slot on the back of the swirl. The Bete Twister provides force more evenly across the slot so that it can remove swirls in most stuck nozzle situations, while preventing costly damage.

Custom Spray Nozzle Solutions – Dairy Industry Swirl Units Drawings and Sketches: