Custom Spray Nozzle Solutions – Cool and Remove Plastic Pellets from Cutter

Application #071213

Industry: Chemical Processing

Application: Cool and Remove Plastic Pellets from Cutter

Product Description: 1/8″ Bete NF 06-65 in Stainless Steel

Situation: A polymer processing company used Bete’s Application Intake Sheet to detail their potential application. The company needed to cut large polymer cylinders into pellets for use in other processes. To cut the cylinders into pellets, a series of knives heated to over 400°F (204.4°C) act as a die to whittle down bulk polymer. The company proposed that a nozzle be used to both cool the cut pellets and remove them from the blade.

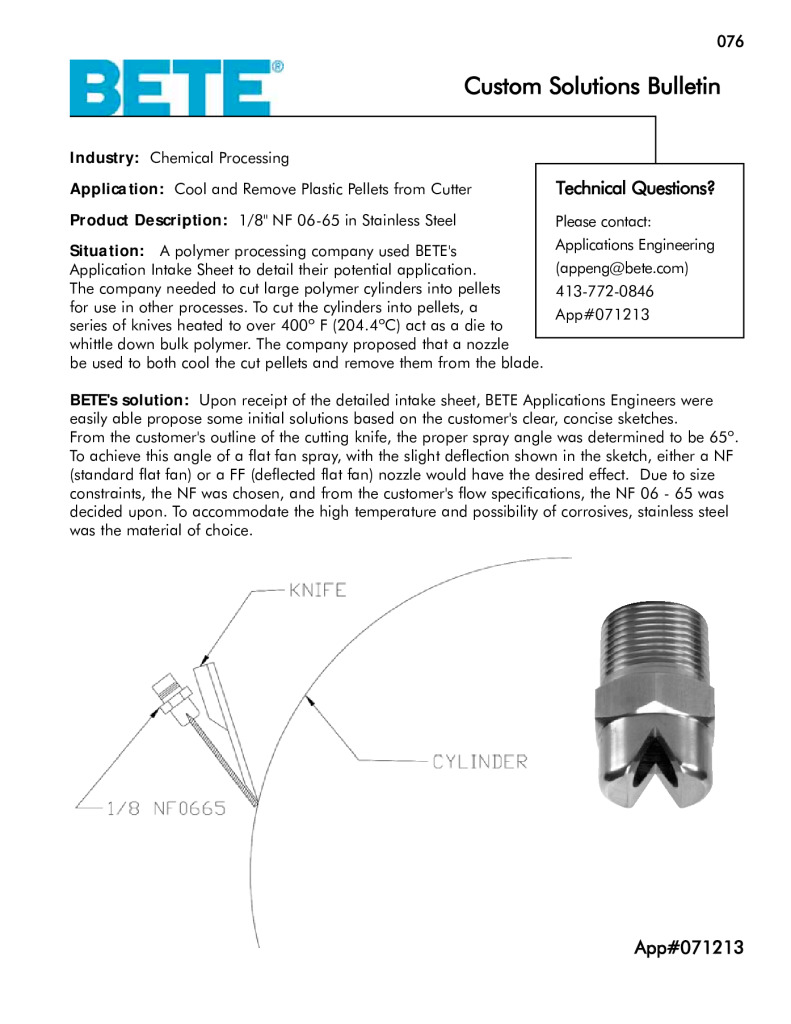

Solution: Upon receipt of the detailed intake sheet, Bete Applications Engineers were easily able propose some initial solutions based on the customer’s clear, concise sketches. From the customer’s outline of the cutting knife, the proper spray angle was determined to be 65°. To achieve this angle of a flat fan spray, with the slight deflection shown in the sketch, either a Bete NF (standard flat fan) or a Bete FF (deflected flat fan) nozzle would have the desired effect. Due to size constraints, the NF was chosen, and from the customer’s flow specifications, the NF 06 – 65 was decided upon. To accommodate the high temperature and possibility of corrosives, stainless steel was the material of choice.

Custom Spray Nozzle Solutions – Cool and Remove Plastic Pellets from Cutter Drawings and Sketches: