Custom Spray Nozzle Solutions – Dairy Processor Spray Dryer

Application #031343

Industry: Food Processing

Application: Spray Drying

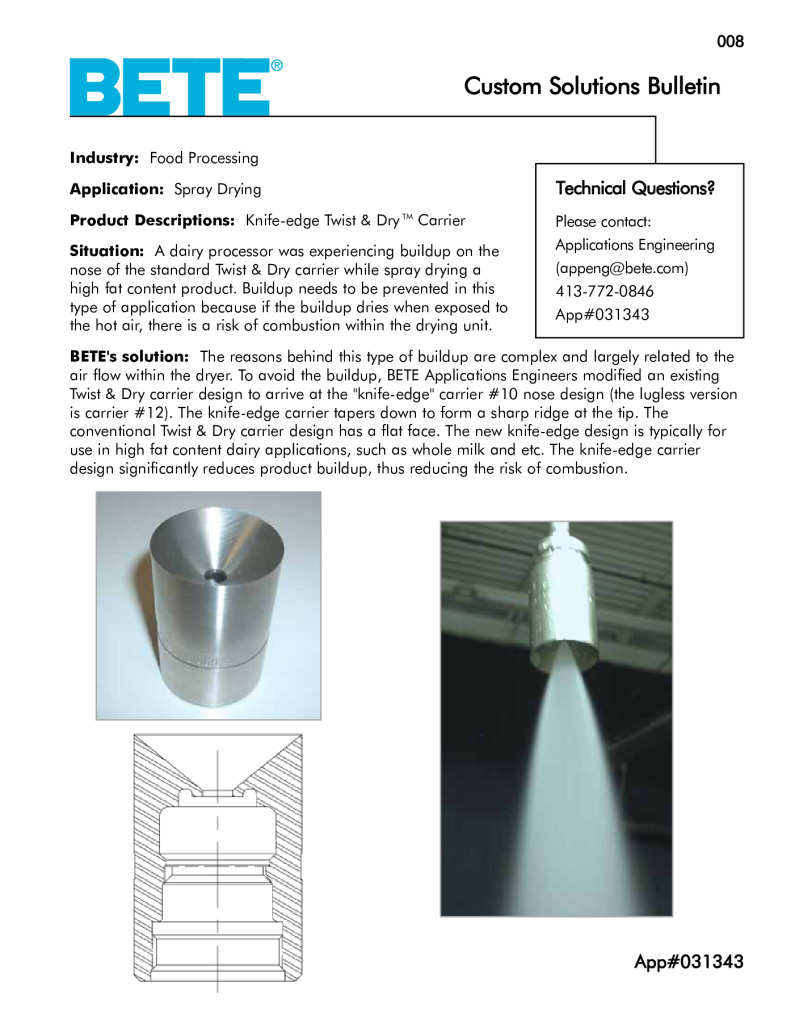

Product Description: Knife-edge Bete Twist & Dry (TD) Carrier

Situation: A dairy processor was experiencing buildup on the nose of the standard Twist & Dry carrier while spray drying a high fat content product. Buildup needs to be prevented in this type of application because if the buildup dries when exposed to the hot air, there is a risk of combustion within the drying unit.

Solution: The reasons behind this type of buildup are complex and largely related to the air flow within the dryer. To avoid the buildup, Bete Applications Engineers modified an existing Twist & Dry carrier design to arrive at the “knife-edge” carrier #10 nose design (the lugless version is carrier #12). The knife-edge carrier tapers down to form a sharp ridge at the tip. The conventional Twist & Dry carrier design has a flat face. The new knife-edge design is typically for use in high fat content dairy applications, such as whole milk and etc. The knife-edge carrier design significantly reduces product buildup, thus reducing the risk of combustion.

Custom Spray Nozzle Solutions – Dairy Processor Spray Dryer Drawings and Sketches: