Custom Spray Nozzle Solutions – Air Blow Away Fume System

Application #041493

Industry: Utilities

Application: Air Blow-off

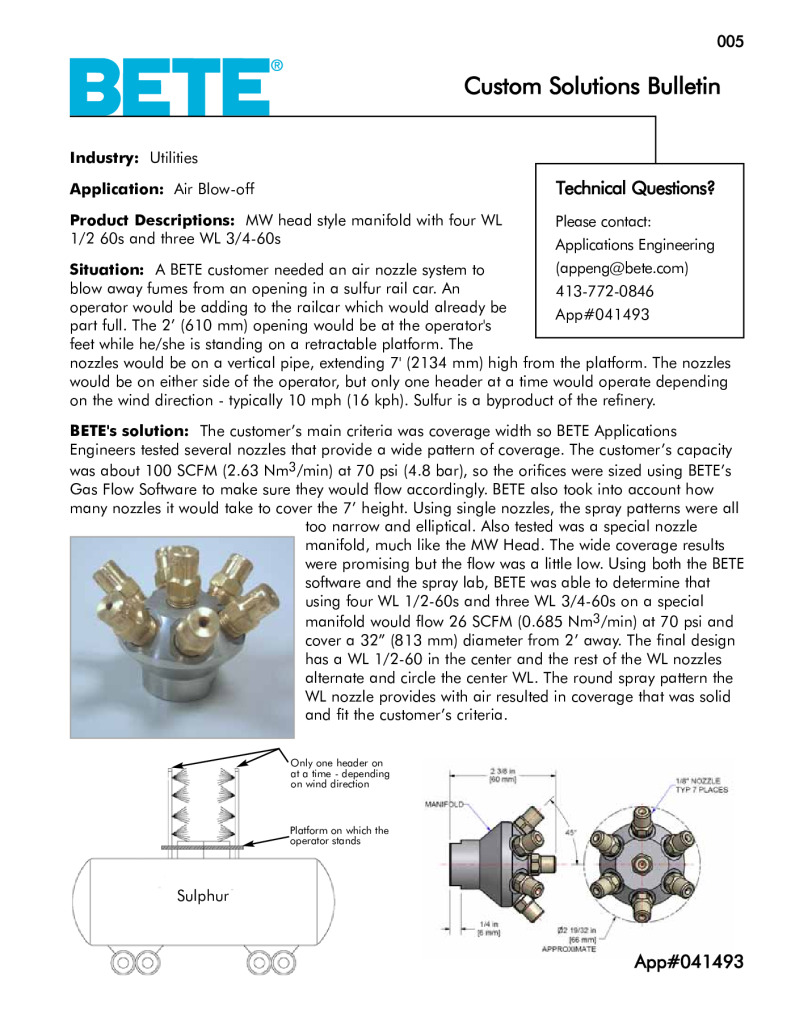

Product Description: Bete MW Head-style manifold with four WL 1/2-60s and three WL 3/4-60s

Situation: A Bete customer needed an air nozzle system to blow away fumes from an opening in a sulfur rail car. An operator would be adding to the railcar that would already be part full. The 2′ (610 mm) opening would be at the operator’s feet while he/she is standing on a retractable platform. The nozzles would be on a vertical pipe, extending 7′ (2134 mm) high from the platform. The nozzles would be on either side of the operator, but only one header at a time would operate depending on the wind direction – typically 10 mph (16 kph). Sulfur is a byproduct of the refinery.

Solution: The customer’s main criteria was coverage width so Bete Applications Engineers tested several nozzles that provide a wide pattern of coverage. The customer’s capacity was about 100 SCFM (2.63 Nm³/min) at 70 psi (4.8 bar), so the orifices were sized using Bete’s Gas Flow Software to make sure they would flow accordingly. Bete also took into account how many nozzles it would take to cover the 7′ height. Using single nozzles, the spray patterns were all too narrow and elliptical. Also tested was a special nozzle manifold, much like the MW Head. The wide coverage results were promising but the flow was a little low. Using both the Bete software and the spray lab, Bete was able to determine that using four WL 1/2-60s and three WL 3/4-60s on a special manifold would flow 26 SCFM (0.685 Nm³/min) at 70 psi and cover a 32″ (813 mm) diameter from 2′ away. The final design has a WL 1/2-60 in the center and the rest of the WL nozzles alternate and circle the center WL. The round spray pattern the WL nozzle provides with air resulted in coverage that was solid and fit the customer’s criteria.

Custom Spray Nozzle Solutions – Air Blow Away Fume System Drawings and Sketches: