Cornell PP Series Food Processing Pumps

- 4″ through 12″ discharge size

- Flows to 8300 GPM and Heads to 165 feet

Cornell introduced the first Hydro-Transport food process pump to the industry almost 40 years ago. Unlike Solids Handling pumps, or other types of pumps, that are sometimes used in the food industry the Cornell P and PP series pumps are designed and manufactured with the sole purpose of pumping food products. The Cornell Food Process pumps have the lowest product damage rates in the industry and are the pump of choice for food processors around the world

Features and Benefits

- Ductile iron construction

- Oversized, offset volute

- No volute cutwater

- Single vane impeller

- Smooth contours

- Reduced product damage

- Low cost of repair

- Threaded impeller

- Food grade packing

- No product contamination

- Heavy “stressproof” steel shaft

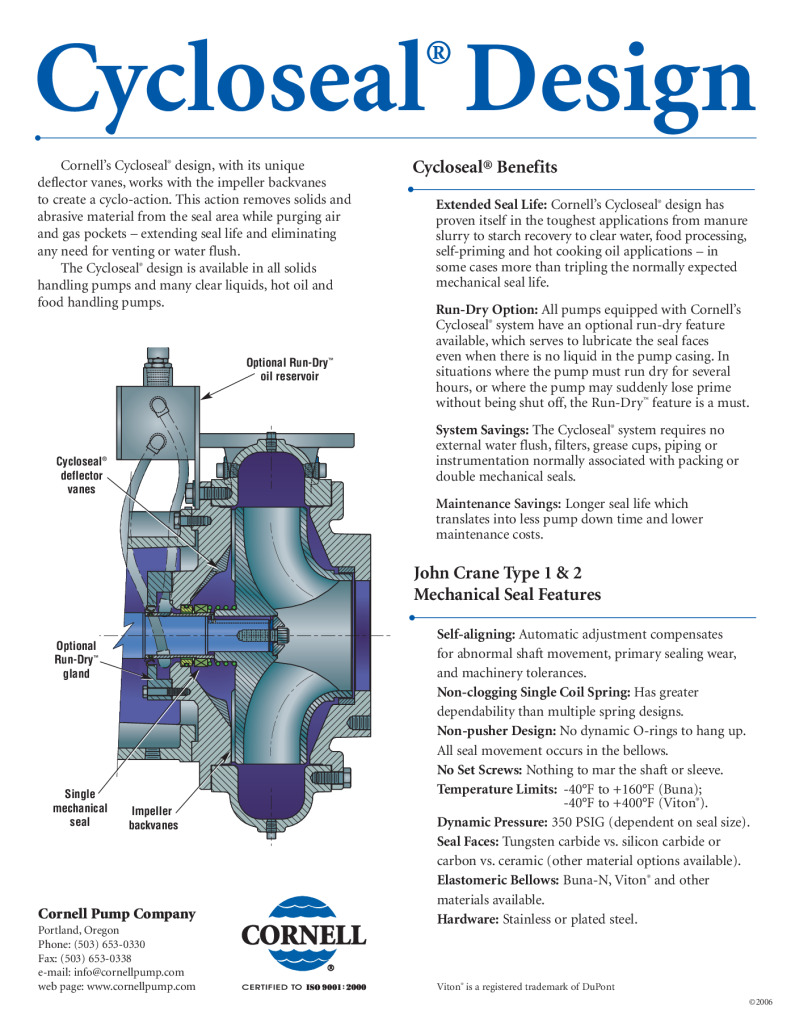

- Cycloseal Design Available

- Back-to-back double lip seals

- Extended mechanical seal life

- Oversized bearings

- Extended bearing life

- Replaceable shaft sleeve

- Dynamically balanced impeller

- Stainless Steel option

- Two-year warranty

- Confidence in product

Applications Include:

- Potatoes

- Live Fish

- Cranberries

- Carrots

- Apples

- Cherries

- Peas

- Broccoli

- Crayfish

- Shrimp

- Lettuce

- Green beans

- Nuts

- Peppers

- Olives

- Cucumbers

- Raisins

- Beans

- Corn

- Peaches

- Beets

- Oranges

- Other whole foods

- French fries

- Potato chips

- Other cut foods

For more information contact us at 1-877-624-5757