Bete XAER : Air Atomizing, Pressure Fed, External Mix, Round Spray Nozzle

Air Atomizing Nozzle Suits High Viscosity Fluids

The Bete XAER spray nozzle is part of the Bete XA nozzle system. It uses the energy in compressed air to produce highly atomized sprays at low flow rates.

Design Features of the Bete XAER Air Atomizing, Pressure Fed, External Mix, Round Spray Nozzle

– External mix: allows spraying of viscous materials

– Able to spray high viscosity (100+ cP) fluids which require a round spray pattern

– Liquid flow rate is controlled only by the liquid pressure. Liquid flow rate is not dependent on the air pressure making the nozzle performance easier to control.

– Variable atomization

– Narrow spray angle (10° to 30°)

– Precise metering of the liquid flow rate

The BETE XAER air atomizing spray nozzle provides a full cone round spray pattern for liquids and is especially suited for liquids with a high viscosity (100+ cP). The round pattern XAER complements the existing XAEF nozzle, which produces a flat fan spray pattern.

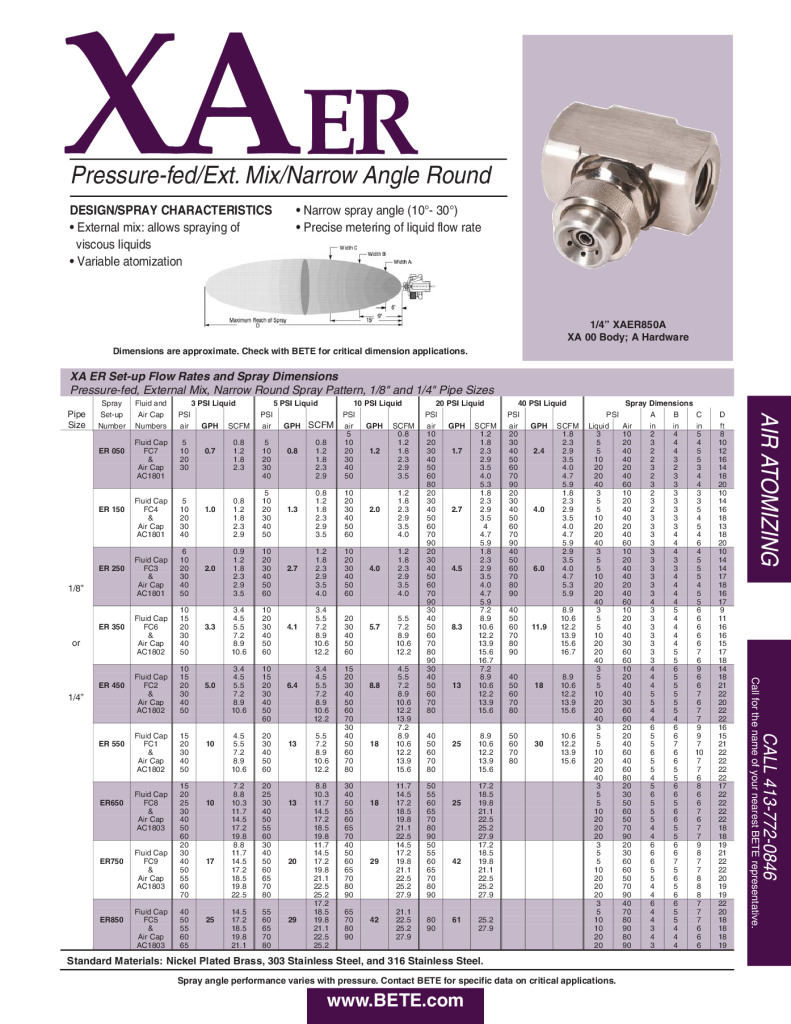

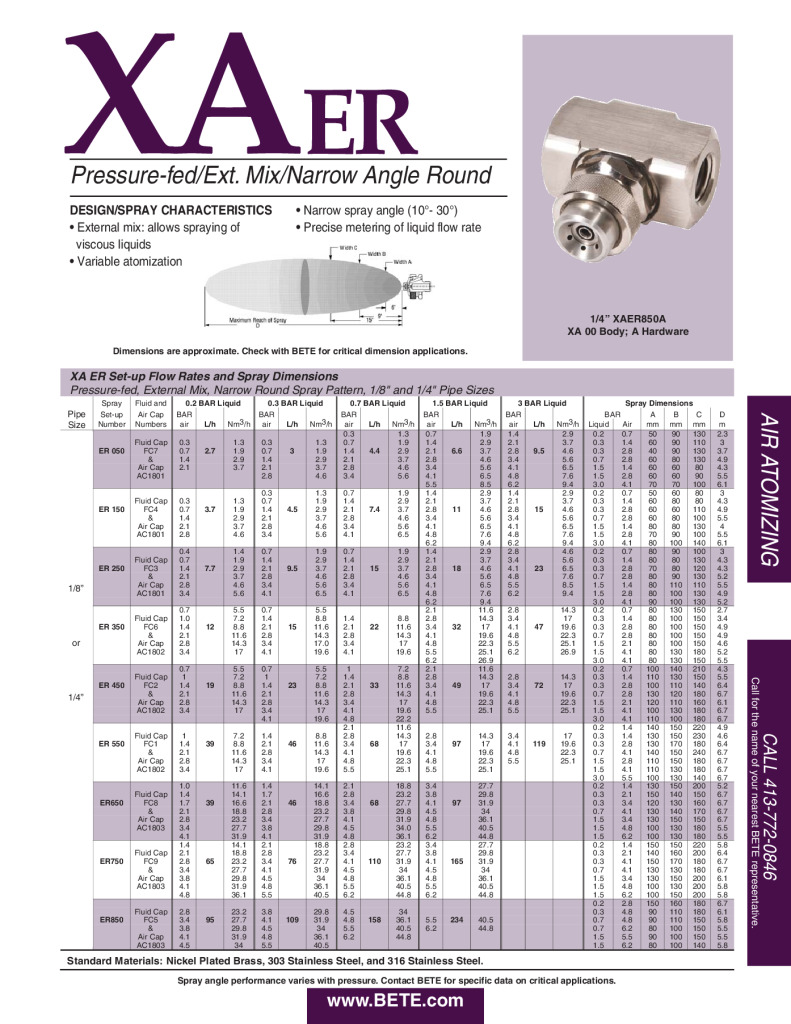

The Bete XAER spray nozzle operates with an external mix, which means the atomization of the fluid takes place outside the nozzle. As the XAER is an external mix, (as opposed to an internal mix), the flow rate is not dependent on the air pressure, which results in easier control. It is available for 1/8″ and ¼” pipe sizes and can be specified in a choice of standard materials including nickel-plated brass, 303 or 316 stainless steel. The Bete XAER can also be constructed from other materials to accommodate demanding conditions.

Typical applications include spray drying, where the fluid pressure is typically lower and the fluid viscosities are typically higher. Other applications for the BETE XAER nozzle include gas cooling and coating foodstuffs. The versatility of the nozzle is demonstrated by one of its more unique applications, injecting a viscous liquid into a gas stream that contains powder particles in order to coat the powder with the liquid.

Applications for Bete XAER spray nozzles:

– Air Atomizing

– Air Conditioning

– Coating

– Concrete Curing

– Cooling: Evaporative

– Fogging

– Humidification

– Lubrication

– Misting

– Moistening

– Odor Control

– Scrubbing: Conditioning

– Scrubbing: Dry