Bete XA Spray Nozzles

The Bete XA nozzle system uses the energy in compressed air to produce highly atomized sprays at low flow rates. There are many interchangeable components that can be assembled to achieve a variety of spraying objectives.

SPRAY SET-UPS

Bete XA nozzles produce eight distinctly different types of sprays, depending on which interchangeable air and fluid caps are selected. The spray type and flow rate are determined by the ”set-up”—a specific combination of one air cap and one fluid cap.

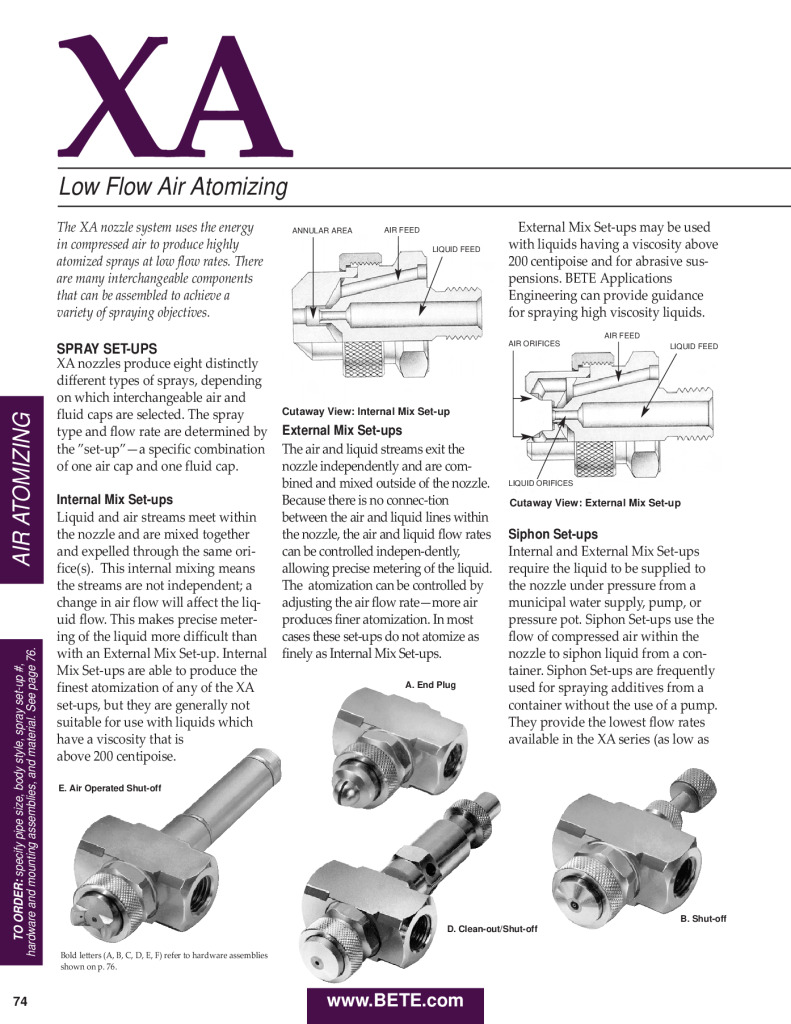

Internal Mix Set-ups:

Liquid and air streams meet within the nozzle and are mixed together and expelled through the same orifice(s). This internal mixing means the streams are not independent; a change in air flow will affect the liquid flow. This makes precise metering of the liquid more difficult than with an External Mix Set-up. Internal Mix Set-ups are able to produce the finest atomization of any of the Bete XA set-ups, but they are generally not suitable for use with liquids which have a viscosity that is above 200 centipoise.

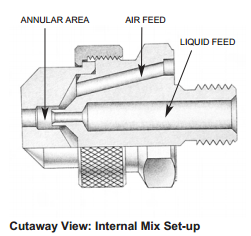

External Mix Set-ups

The air and liquid streams exit the nozzle independently and are combined and mixed outside of the nozzle. Since there is no connection between the air and liquid lines within the nozzle, the air and liquid flow rates can be controlled independently, allowing precise metering of the liquid. The atomization can be controlled by adjusting the air flow rate—more air produces finer atomization. In most cases these set-ups do not atomize as finely as Internal Mix Set-ups. External Mix Set-ups may be used with liquids having a viscosity above 200 centipoise and for abrasive suspensions. We can provide guidance for spraying high viscosity liquids.

BASIC OPERATION

The basic Bete XA nozzle assembly consists of a body, a spray set-up, and a “hardware assembly” that can provide shut-off and clean-out capabilities.

Non-Automatic Operation:

The XA00 Square Body is the basic component of a non-automatic XA nozzle. Air and liquid feeds are located at opposite ends, perpendicular to the spray.

The XA03 Body has air and liquid feeds on one side, perpendicular to the spray axis.

The XA05 Body has air and liquid inlets located in-line with the spray. Hardware assemblies cannot be used with the XA05 body.

Hardware Assemblies for Non-Automatic Operation:

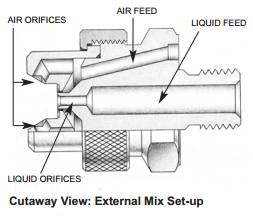

A. Plug. The minimum option hardware assembly required for XA operation. Provides neither clean-out nor shut-off.

B. Shut-off. Turning the knurled knob will stop the flow of liquid to the nozzle. Should not be used to meter the flow of liquid.

C. Clean-out. Pressing the spring-loaded plunger will force a small dia-meter rod through the liquid orifice, cleaning any obstruction. Useful for intermittent spraying of a liquid that may dry in the orifice when not in use.

D. Clean-out/Shut-off. Combines functions of hardware assemblies B and C in one unit. For critical applications which require automatic, no-drip, or highspeed spray shut-off, the XA can be supplied with an air-cylinder operated shut-off or clean-out/shutoff. These air cylinders provide virtually instantaneous liquid shut-off at rates of up to 180 cycles per minute. The air cylinders require a minimum of 30 PSI.

BETE XAAD Air Atomizing Spray Nozzles

Spray Nozzle – Air Atomizing, Pressure Fed, Hollow Cone, Internal Mix Nozzles...

BETE XAEF Spray Nozzles

Bete XAEF : Air Atomizing, Pressure Fed, and Flat Fan Spray Nozzle...

BETE XAER Spray Nozzles

Bete XAER : Air Atomizing, Pressure Fed, External Mix, Round Spray Nozzle...

BETE XAFF Air Atomizing Spray Nozzles

Bete XAFF Spray Nozzle: Air Atomizing, Pressure Fed, and Flat Fan Nozzle...

BETE XAPF Air Atomizing Spray Nozzles

Bete XAPF Spray Nozzle – Air Atomizing, Pressure Fed, and Flat Fan...

BETE XAPR Internal Mix Spray Nozzles

Air Atomizing, Pressure Fed, and Narrow Angle Injector Nozzle Bete XAPR spray...

BETE XASF Air Atomizing Siphon Fed Flat Fan Spray Nozzles

Bete XASF : Air Atomizing and Siphon-fed Flat Fan Nozzle John Brooks Company...

BETE XASR Air Atomizing Siphon Fed Full Cone Spray Nozzles

Bete XASR Spray Nozzle : Air Atomizing and Siphon Fed Round Full Cone Nozzle...

BETE XAXW Extra Wide Hollow Cone Spray Nozzles

Air Atomizing, Pressure Fed, Extra-wide Hollow Cone Spray Nozzles Bete XAXW spray...