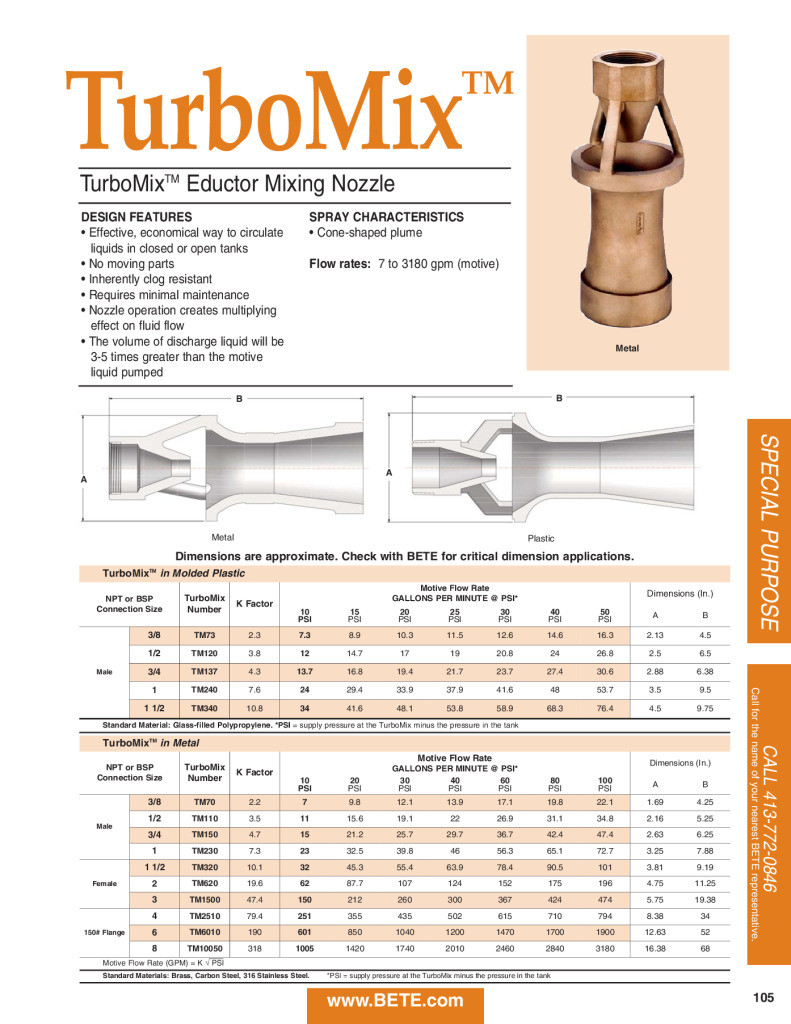

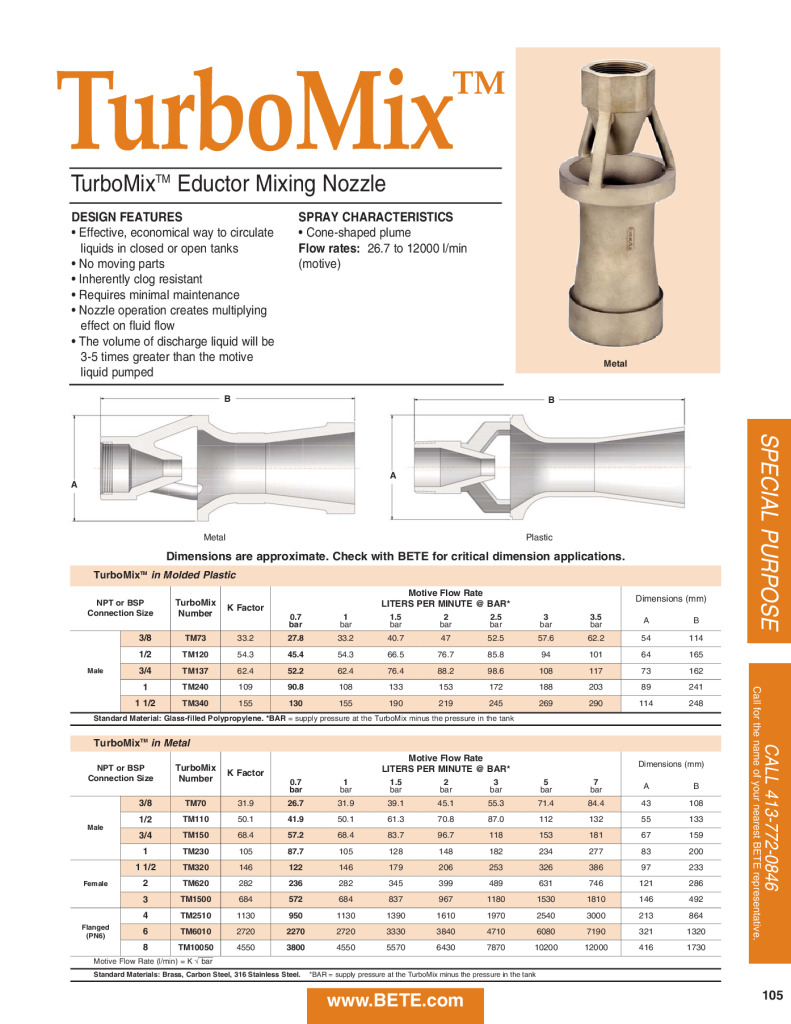

Bete TurboMix Eductor Nozzle for Clog-Resistant Agitation and Mixing

Design Features of the Bete TurboMix Eductor Nozzle for Clog-resistant Agitation and Mixing

– Effective, economical way to circulate liquids in closed or open tanks

– No moving parts

– Inherently clog resistant

– Requires minimal maintenance

– Available in both plastic and metal construction

– Nozzle operation creates multiplying effect on fluid flow; the volume of discharge liquid will be 3-5 times greater than the motive liquid pumped

Spray Characteristics of the Bete TurboMix Eductor Mixing Nozzle

– Cone-shaped plume

Flow rates: 7 to 3180 gpm (26.7 to 12000 L/min) (motive)

Recent Applications:

Fire protection water storage tanks. The water in these tanks is stagnant, often stays there for an extended period of time, and can form thermally stratified layers. Creating movement in the tank decreases bacterial growth. You can also use the nozzles for efficient adding and mixing of chlorine or other water additives. Mixing also reportedly decreases ice formation in winter by keeping the water moving

Clearing sediment. A customer is pumping water from a river into a pond and wants to keep the area under and around the pump clear of sediment. Bete TurboMix eductor nozzles are arranged to keep water flowing across these surfaces and hence keep silt from settling. A similar application in enclosed sump pits is frequent.

Clearing sludge. A customer has a tank in which sludge deposits on the bottom. The mechanical scraper system currently in use is prone to breakage and another removal system is desired. The customer is looking at banks of Bete TurboMix eductor nozzles to push the sludge along the bottom into a removal trough. Using a fluid driven system over a mechanical system minimized downtime as the fluid system has no moving parts in the tank.

General particle agitation. Many applications are for the usual role of the TurboMix, which is to keep particles in suspension by essentially stirring the tank.

Material injection and mixing. A customer had the typical pump-around configuration to keep the liquid in the tank circulating. The situation also existed where they needed to inject a chemical into the tank to keep it within limits. They added an injection port into the pump-around line so that the sulfuric acid could be injected into the line and then mixed efficiently as it emitted through the TurboMix.

Breaking up a grease layer. A bio-fuel customer had a tank in which a layer of grease would form at the surface and harden. They set up a system with a sump pump and Bete TurboMix eductor nozzles pointed at the surface to break up the grease layer and keep it from solidifying into a single mass.