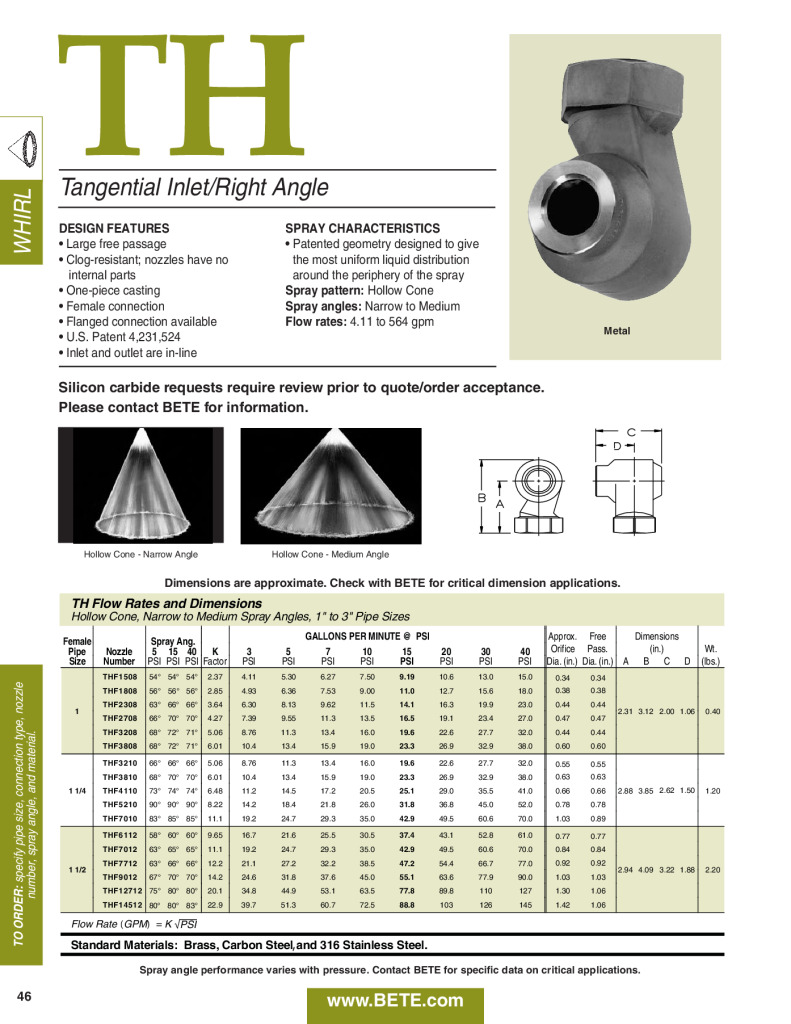

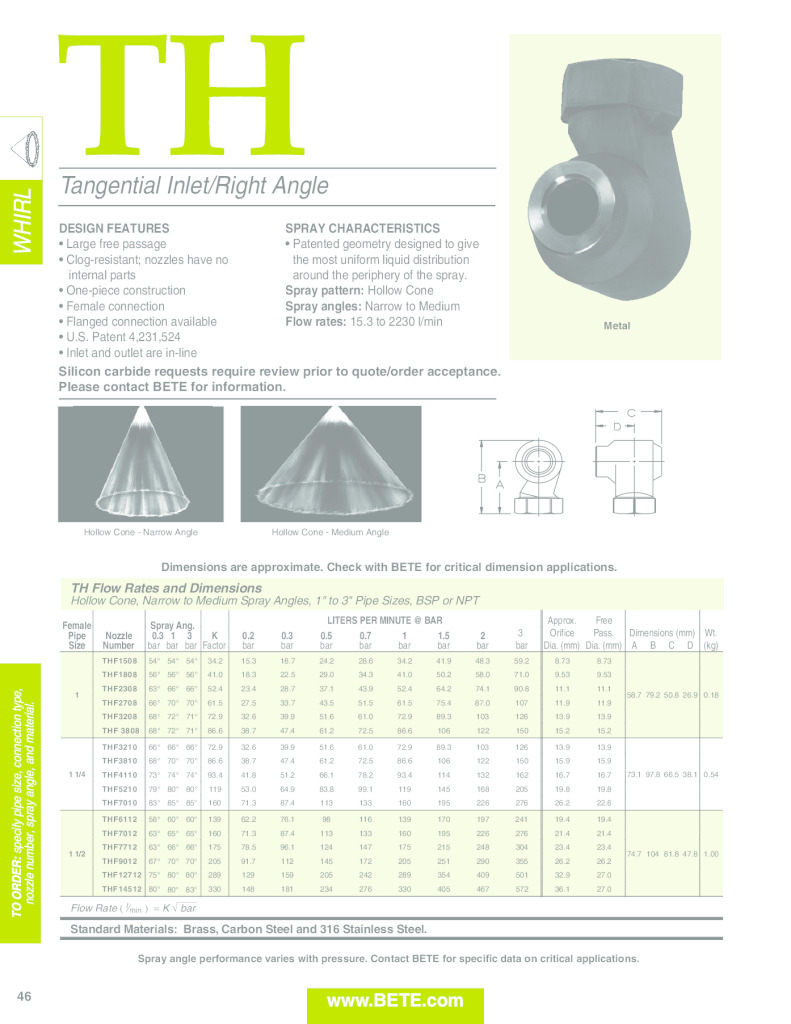

Bete TH Right Angle and Tangential Inlet Nozzle Spray Nozzle

Since the primary cooling mechanism is the evaporation of water, the first consideration in nozzle selection is achieving the smallest possible droplets at the available operating pressure. This is also true in the prescrubber where the gas-liquid contact is the key to effective mass transfer. Select the Bete TH for right angle hollow cone design, which uses a tangential inlet to produce the whirl. The TH is also clog-resistant with no internal parts.

Design Features of the Bete TH Spray Nozzle:

– Large free passage

– Clog-resistant; nozzles have no internal parts

– One-piece casting

– Female connection

– Flanged connection available

– U.S. Patent 4,231,524

– Inlet and outlet are in-line

Spray Characteristics of the Bete TH Spray Nozzle:

– Most even spray distribution of any tangential whirl nozzle in the industry

Spray Patterns: Hollow Cone

Spray Angles: Narrow to Medium

Flow rates: 4.11 to 564 gpm (15.3 to 2230 L/min)

Materials:

– 316 Stainless Steel

– Nickel Alloy C

– Nitride Bonded Silicon Carbide (SNBSC)

– Other materials on application.

Applications:

– Absorption

– Clog Resistance

– Cooling: Pond

– Pollution Control

– Scrubbing: Direct Contact

Hollow Cone- Narrow Angle Visual:

Hollow Cone- Medium Angle Visual: