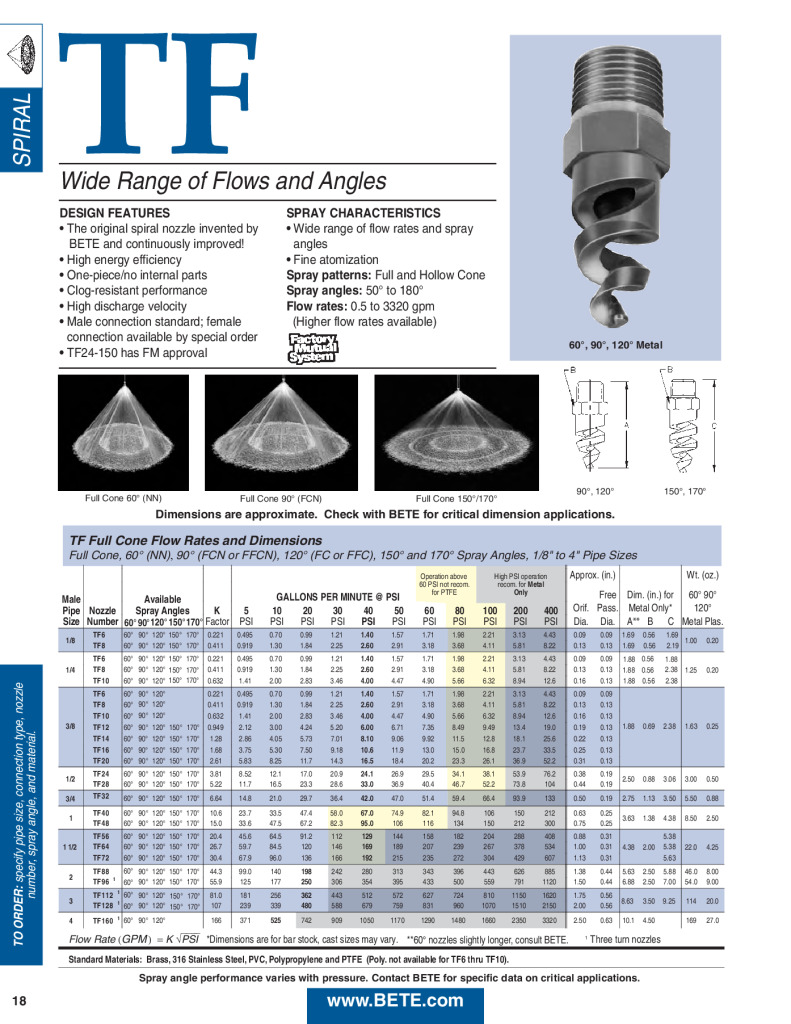

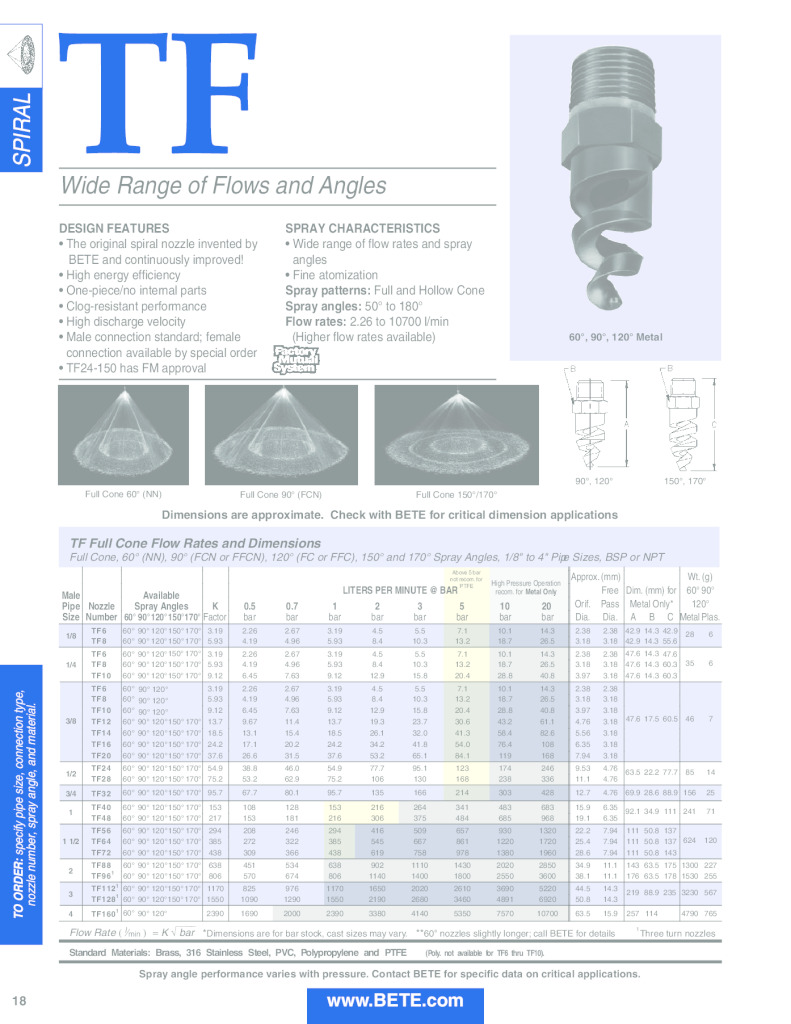

Bete TF Spiral Spray, Fogging, Misting, and Evaporative Cooling Nozzles in a Wide Range of Flows and Angles; Full Cone Nozzles, Hollow Cone Nozzles, Misting Nozzles with a Wide Range of Flows and Angles, Full Cone Nozzles, Hollow Cone Nozzles, Misting Nozzles

Bete TF original spiral nozzle design remains one of the major advances in nozzle technology. The liquid is atomized into small droplets by continuously descending spiral and, therefore enters and exits with no internal restrictions through relatively large passages. The result is a higher discharge velocity so lower pumping pressures can be used to produce the required atomization.

Design Features of the Bete TF Spray Nozzle:

- The original spiral nozzle invented by BETE

- Also referred to as pigtail nozzles, corkscrew nozzles and/or helix nozzles

- High energy efficiency

- One-piece/no internal parts

- Clog-resistant performance

- High discharge velocity

- Male connection standard; female connection available by special order

- The TF24-150, and the TF8NN and TF8FCN (in brass) are FM approved

Spray Characteristics of the Bete TF Spray Nozzle:

- Wide range of flow rates and spray angles

- Fine atomization

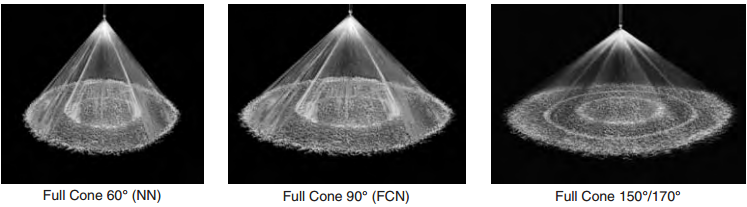

- Spray Patterns: Full Cone and Hollow Cone

- Spray Angles: 50° to 180°

- Flow rates: 0.5 to 3320 gpm (2.26 to 10700 L/min)

(Higher flow rates available)

Applications:

- Absorption

- Aeration

- Cooling: Deluge

- Cooling: Evaporative

- Cooling: Parts

- Cooling: Pond

- Corrosion Resistant Nozzles

- Disposal: Evaporative

- Dust Control: Air-handling Ducts

- Dust Control: Area

- Fire Protection: Deluge

- Fire Protection: Marine

- Fire Protection: Special

- Fire Protection: Toxic Gas Mitigation

- Fire Protection: Water Wall

- Fogging

- Humidification

- Misting

Spray Angle Visual: