BETE TC Full Cone Spray Nozzle

The nozzle characteristics of greatest interest for distributing and mixing should be flow rate and a non-clogging design. Whirl nozzles are most commonly used. Bete’s nozzles are designed to handle many types of mixing and distribution, including FCCU feed distribution nozzles, distributing liquids onto packed beds or mixing chemical compounds. Distribution nozzles usually feature wide spray angles, high through-put, medium-to-coarse atomization, and moderate operating pressures.

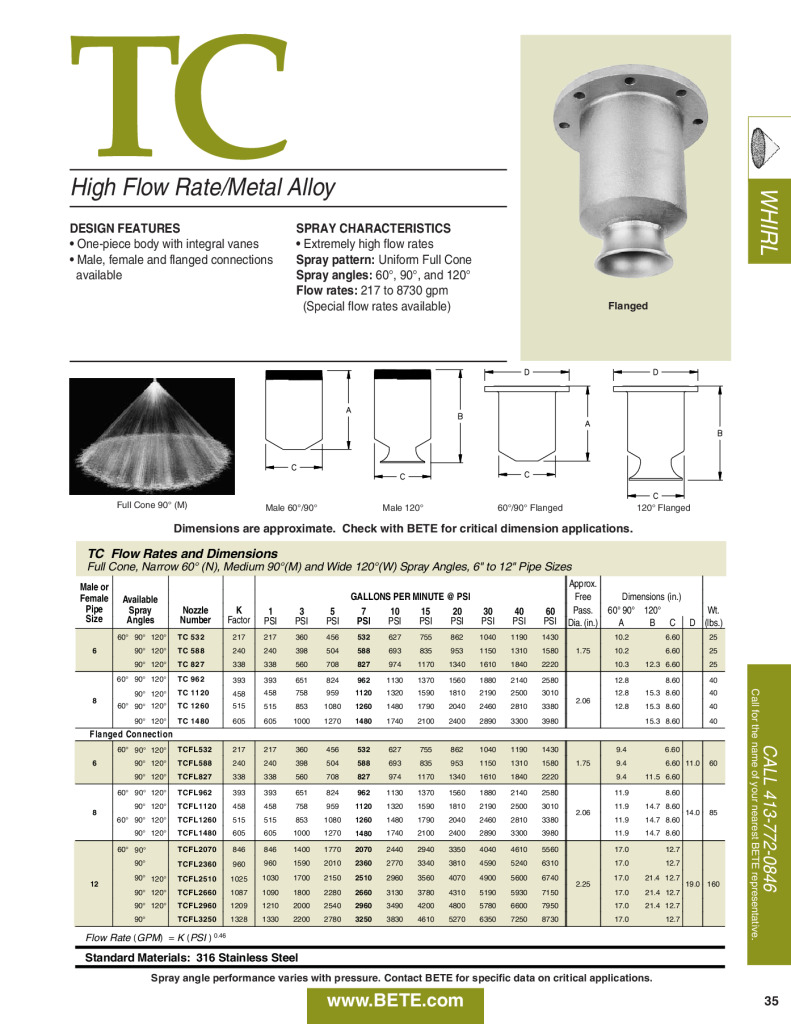

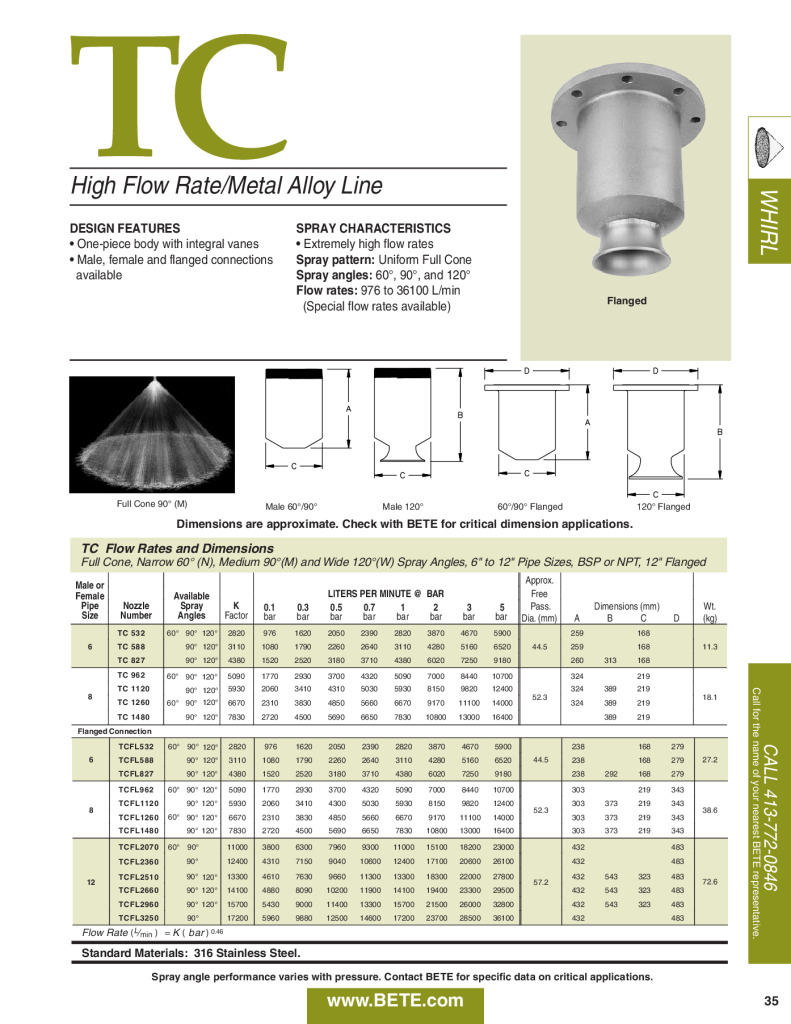

Design Features of the Bete TC High Flow Rate, Metal Alloy, and Full Cone Spray Nozzle:

– One-piece body with integral vanes

– Male, female and flanged connections available

Spray Characteristics of the Bete TC High Flow Rate, Metal Alloy, and Full Cone Spray Nozzle:

– Extremely high flow rates

Bete TC Spray pattern: Uniform Full Cone

Bete TC Spray angles: 60°, 90° and 120°

Bete TC Flow rates: 217 to 8730 gpm (976 to 36100 L/min). Special flow rates available.

Applications:

– Distribution (Distribute fluids uniformly onto packing, foam control, waste water treatment, vacuum distillation, trickle bed media and horticultural beds; VOC stripping)

– Packing (Distribute scrubbing liquor in scrubbers or water in humidifiers)

– Gas cleaning

– Quench cooling

60° Spray Angle Visual:

90° Spray Angle Visual:

120° Spray Angle Visual: