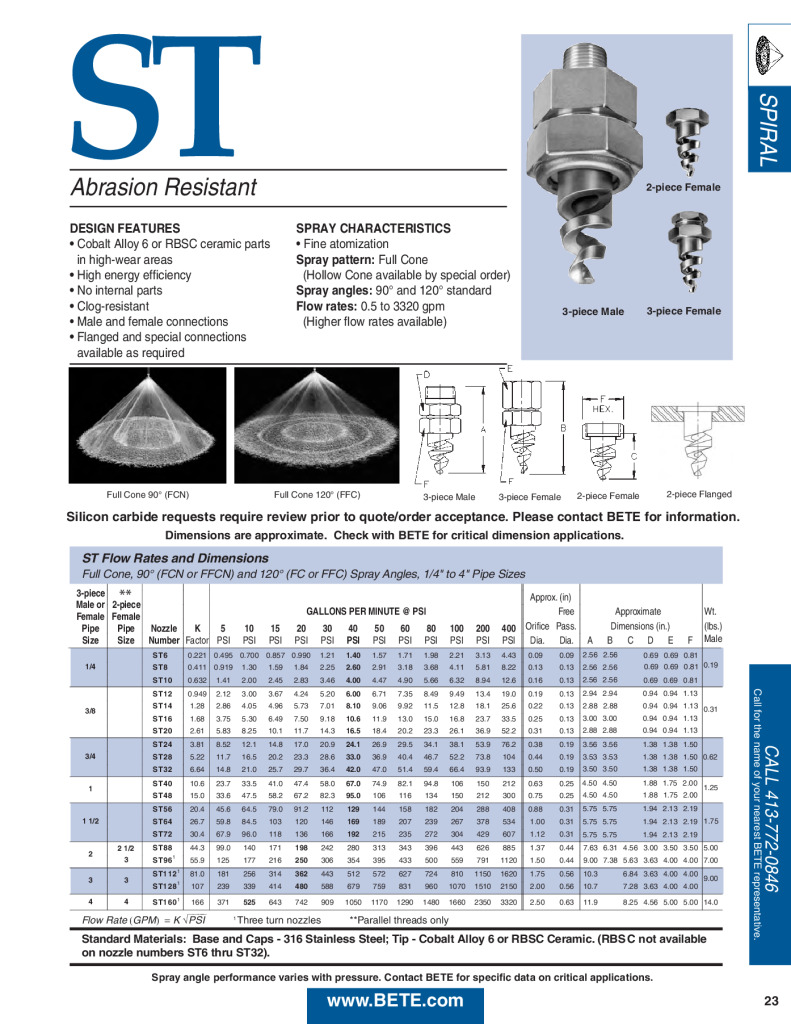

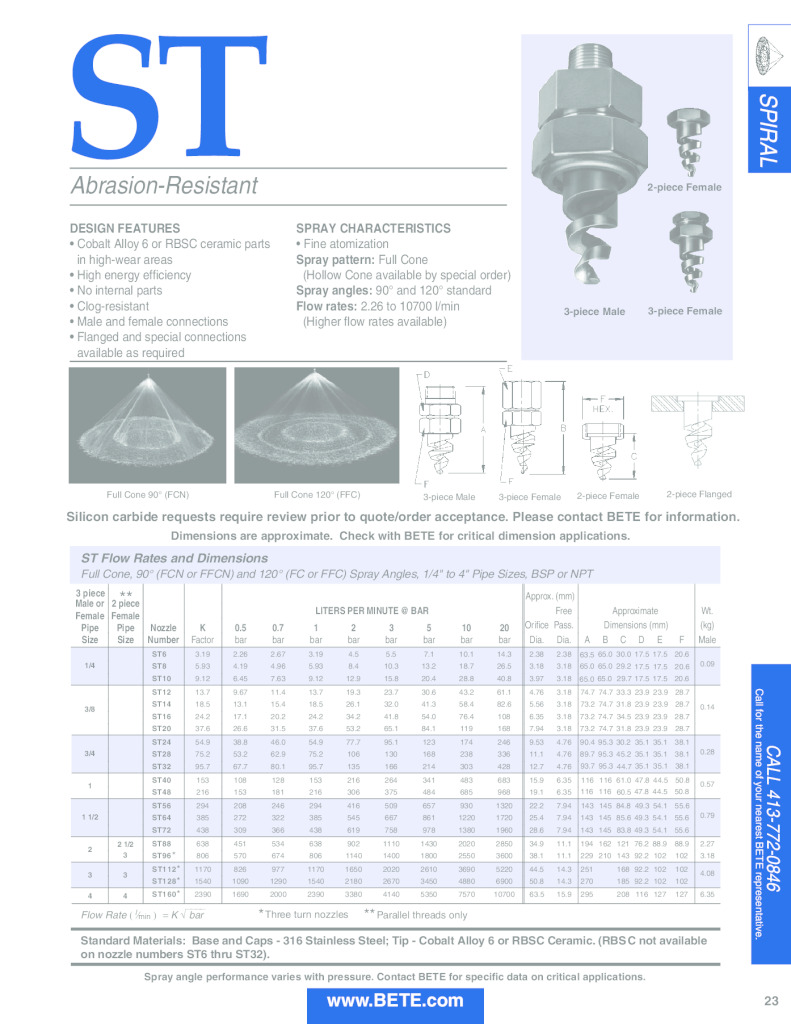

Bete ST Abrasion Resistant Full Cone Spiral Spray Nozzles

Bete ST spiral design remains one of the major advances in nozzle technology. The liquid is atomized into small droplets by a continuously descending spiral and, therefore, enters and exits with no internal restrictions through relatively large passages. The result is a higher discharge velocity so lower pumping pressures can be used to produce the required atomization.

Design Features:

- Designed for use with abrasive materials such as limestone slurry

- Extensive history as a wet FGD (flue gas desulphurization) absorber nozzle

- Available in Cobalt Alloy 6 or industrial ceramic (reaction bonded silicon carbide)

- Inherently clog resistant with no internal parts

- The spiral design produces a spray with more developed surface area than other nozzle styles for a given flow and pressure

- Designed by BETE, the inventor of the spiral nozzle

- Cobalt Alloy 6 or RBSC ceramic parts in high-wear areas

- High energy efficiency

- No internal parts

- Clog-resistant

- Male and female connections

- Flanged and special connections available as required

Spray Characteristics:

- Fine atomization

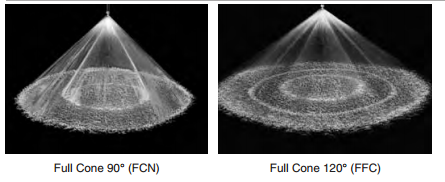

- Spray pattern: Full Cone (Hollow Cone available by special order)

- Spray angles: 90° and 120° standard

- Flow rates: 0.5 to 3320 gpm (2.26 to 10700 L/min). Higher flow rates available.

Bete ST Spray Angle Visuals:

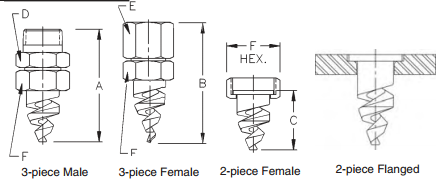

Bete ST Drawings: